Charge transport device, touch induction device and method

A charge transfer and charge technology, applied in the field of touch sensing and touch sensing devices, can solve the problems of complex circuit structure, unable to reflect unknown capacitance size and change, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

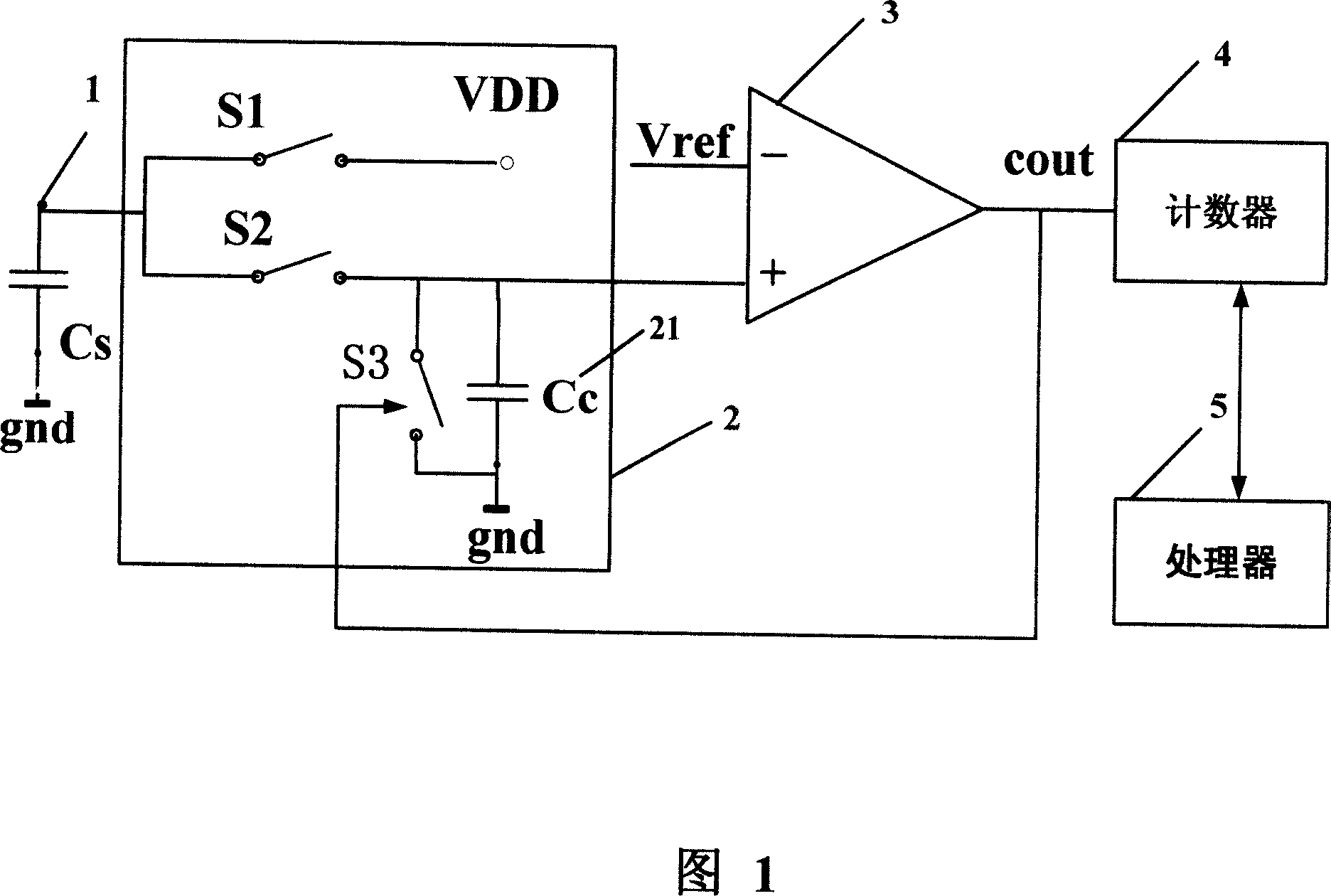

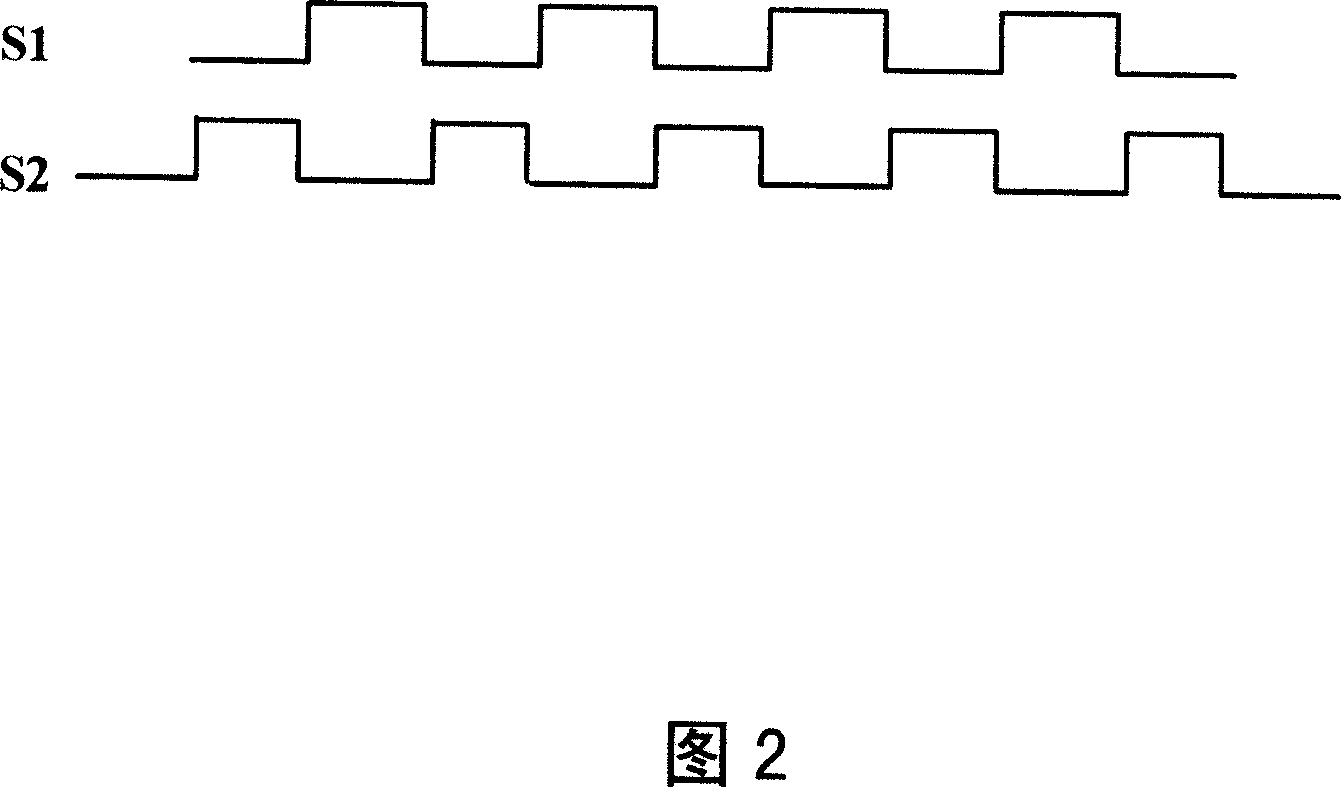

[0061] FIG. 1 is a schematic diagram of a touch sensing device of the present invention. As shown in the figure, it includes: a sensing point 1, a charge transfer device 2, a comparator 3, a counter 4, a processor 5, and a third switch S3.

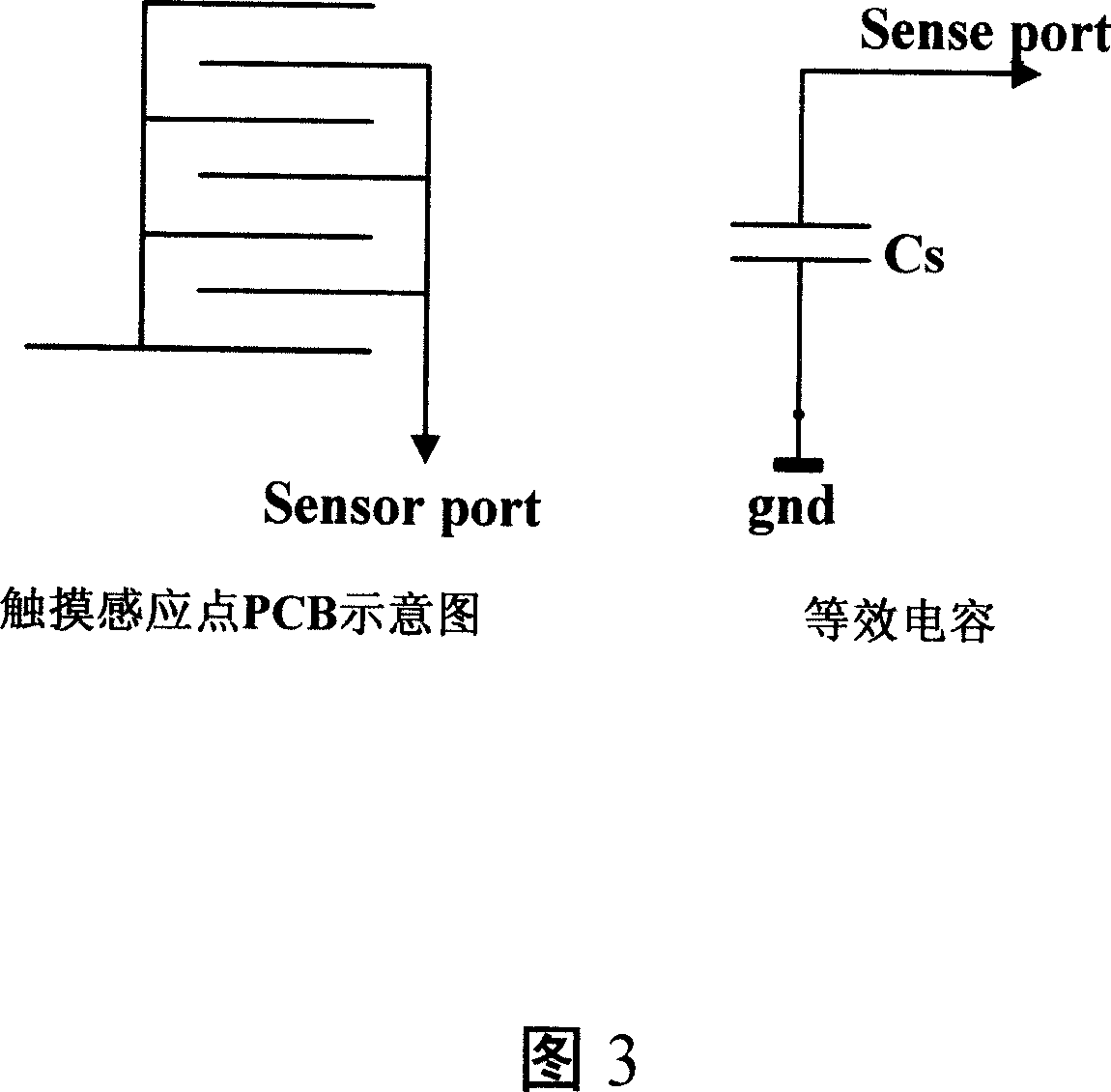

[0062]The sensing point 1 is used to sense the capacitance between different environments and the ground (gnd), thereby generating a sensing capacitance Cs. The sensing point 1 can be formed by PCB traces, and the PCB traces can be made into the shape shown in attached drawing 3, or can be made into the shape shown in attached drawing 4, so as to form the correct sensing capacitance and ensure the smoothness of the sensing action. reliability.

[0063] Since the capacitance Cs generated on the sensing point 1 is very small, and the amount of charge transferred each time is also very small, it is difficult to measure. The present invention provides a charge transfer device 2 capable of accumulating charge, which converts the sensing point...

Embodiment 2

[0082] Since the sensing capacitance Cs generated by the sensing point 1 may change with the temperature and humidity of the external environment, the charging time of the sensing point 1 will also change with the temperature and humidity of the environment where it is located. In this way, as the environment changes, the actual non-touch charging count value T nkn It will change slowly, and when the change difference is greater than the specified standard deviation value, it will also be mistaken for a touch action. In the same way, in the touch state, the environment is still affecting the value of the counter, which may change the value of the counter to a value without touch.

[0083] Therefore, in order to ensure accurate triggering and high sensitivity, it is necessary to evaluate the change of the sensing capacitance Cs generated by sensing point 1. In this way, it is necessary to continuously adjust the non-touch charging count value, and set the standard deviation val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com