Fitting for forming a fluid-conducting connection

A fitting and fluid technology, applied in the direction of pipe/pipe joint/pipe fitting, separation method, filtration and separation, etc., can solve the problems of corrosion resistance, small weight, difficulty in manufacturing fluid joints, deformation, etc., and achieve the effect of high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

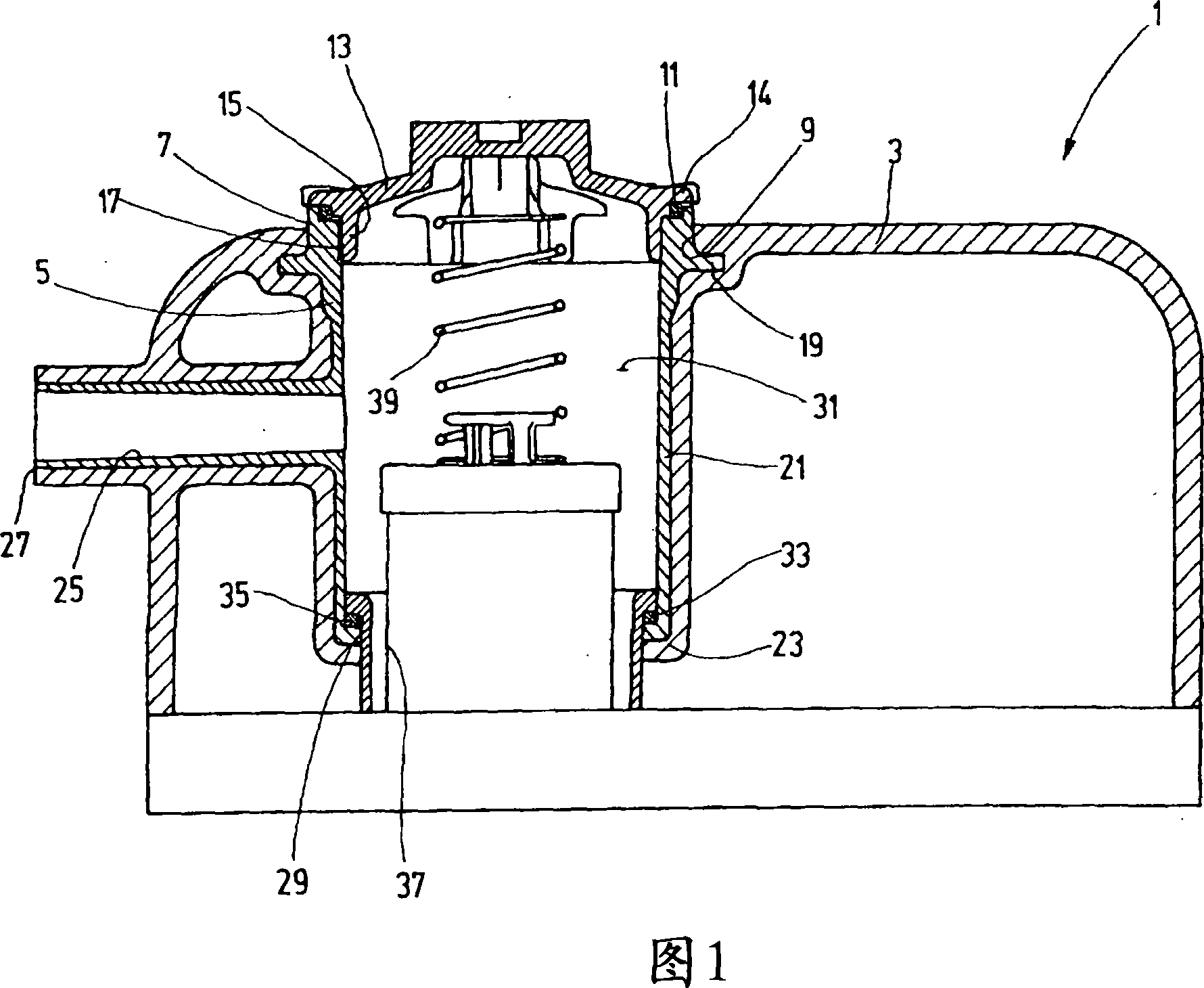

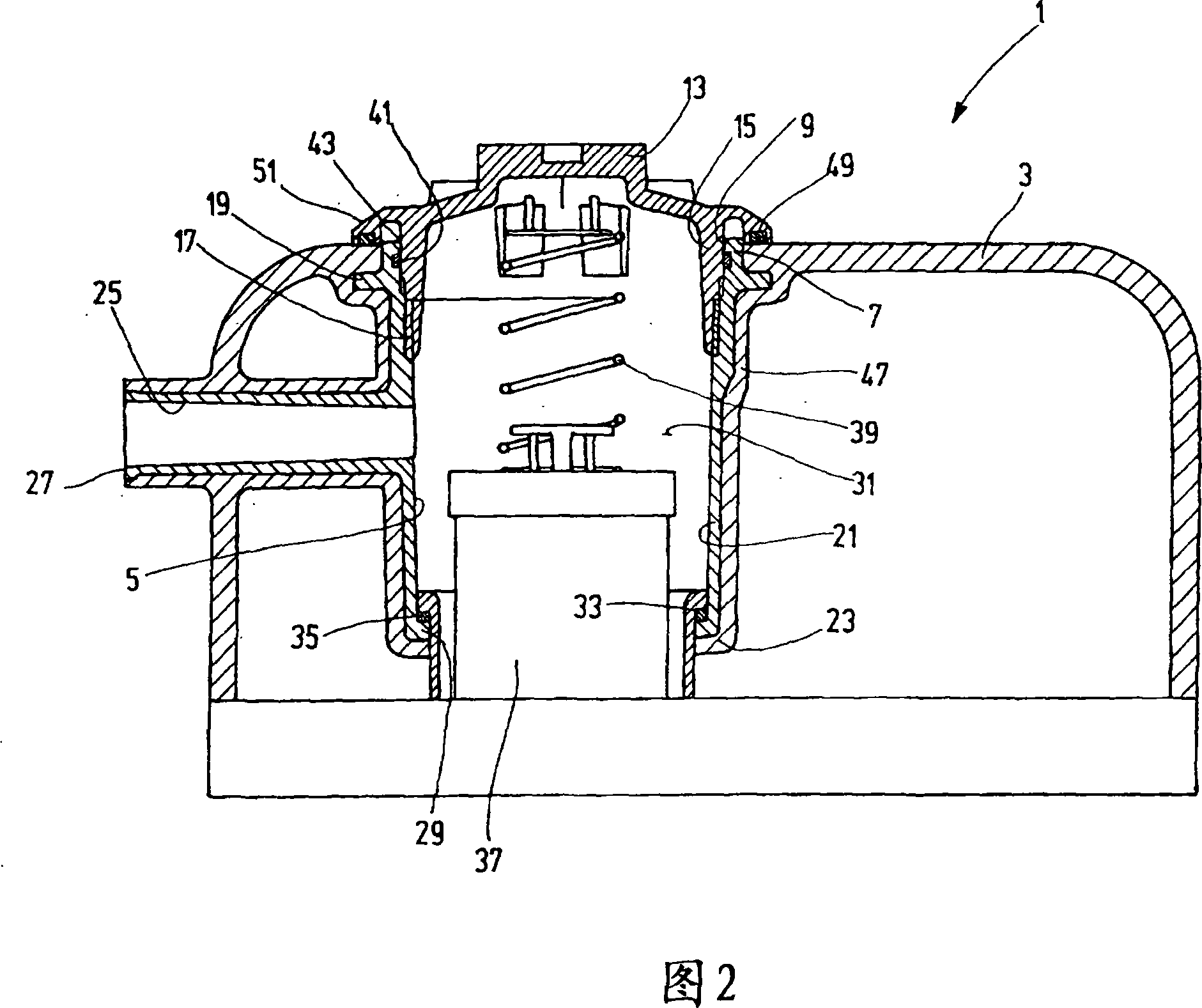

[0019] Figure 1 shows the upper region of a container in the form of a plastic box 1, which is formed by a known method of rotomolding (see Schaab / Stoeckhert's "Guidelines for Plastics Processing Machinery", pages 561-564) from a machine suitable for relatively Manufacture of plastic material for large containers. In the process of rotomolding, a hollow body 5 formed in the form of a cylinder is molded in the plastic wall 3, so that the hollow body 5 abuts against the opening 9 in the wall 3 of the box body 1 with its upper end 7 in the figure. inside. In the example shown in the figure, the end 7 of the hollow body 5 protrudes slightly outside the wall 3, wherein a sealing ring 11 is arranged on this protruding end, which cooperates with a closing element in the form of a screw cap 13 to enable A tight seal and thus a seal of the opening 9 of the container wall 3 is achieved at the end 7 of the hollow body 5 concerned.

[0020] The cover 13 has a threaded part in the form o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com