Structural acoustic sound baffle for automotive sheet metal cavity applications

A technology of acoustic baffles and metal panels, applied in superstructures, superstructure subassemblies, building components, etc., can solve the problems of increasing the weight of rear panel subassemblies, high cost, lack of consistency, etc., to reduce sensitivity , the effect of reducing roar and reducing susceptibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

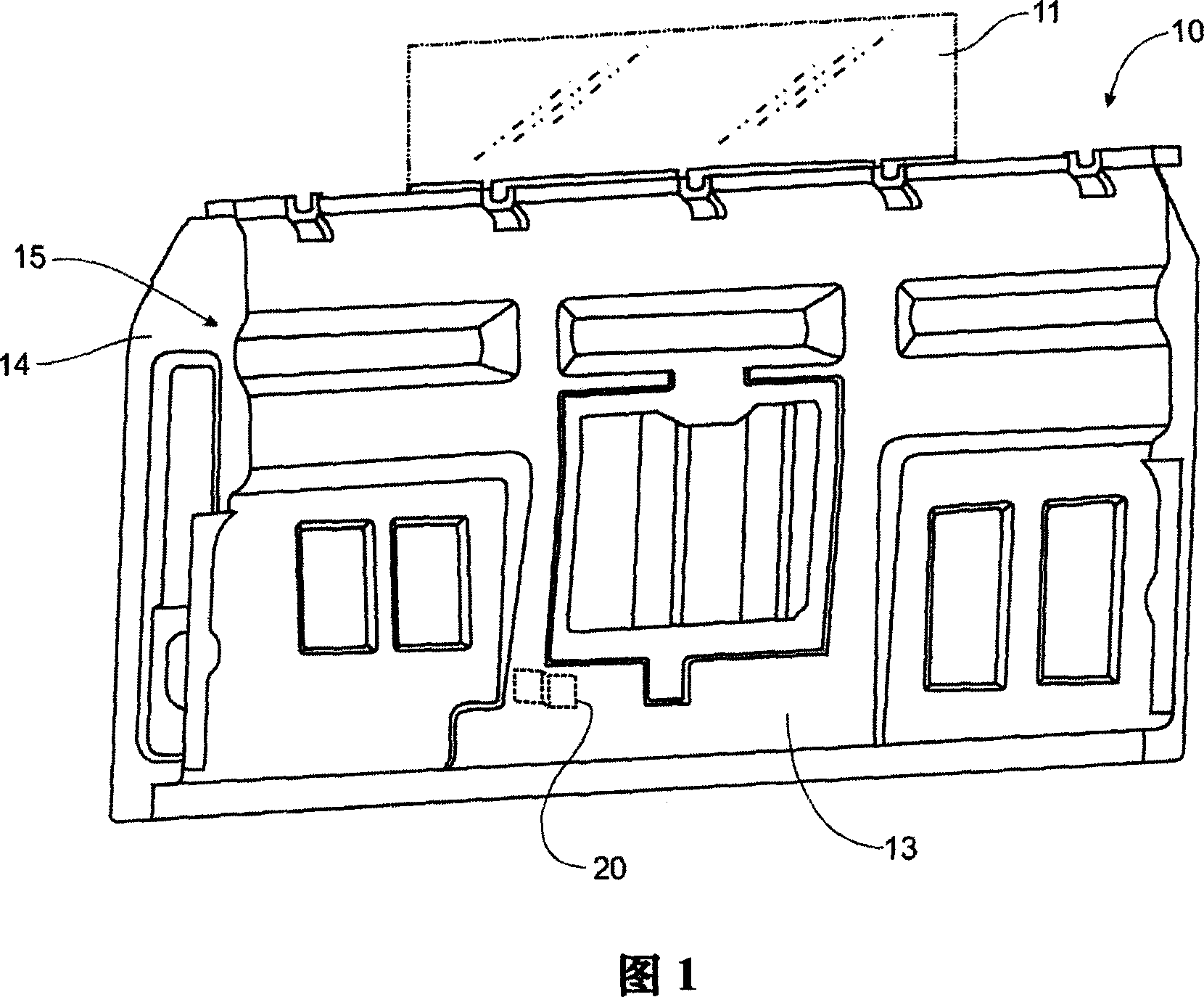

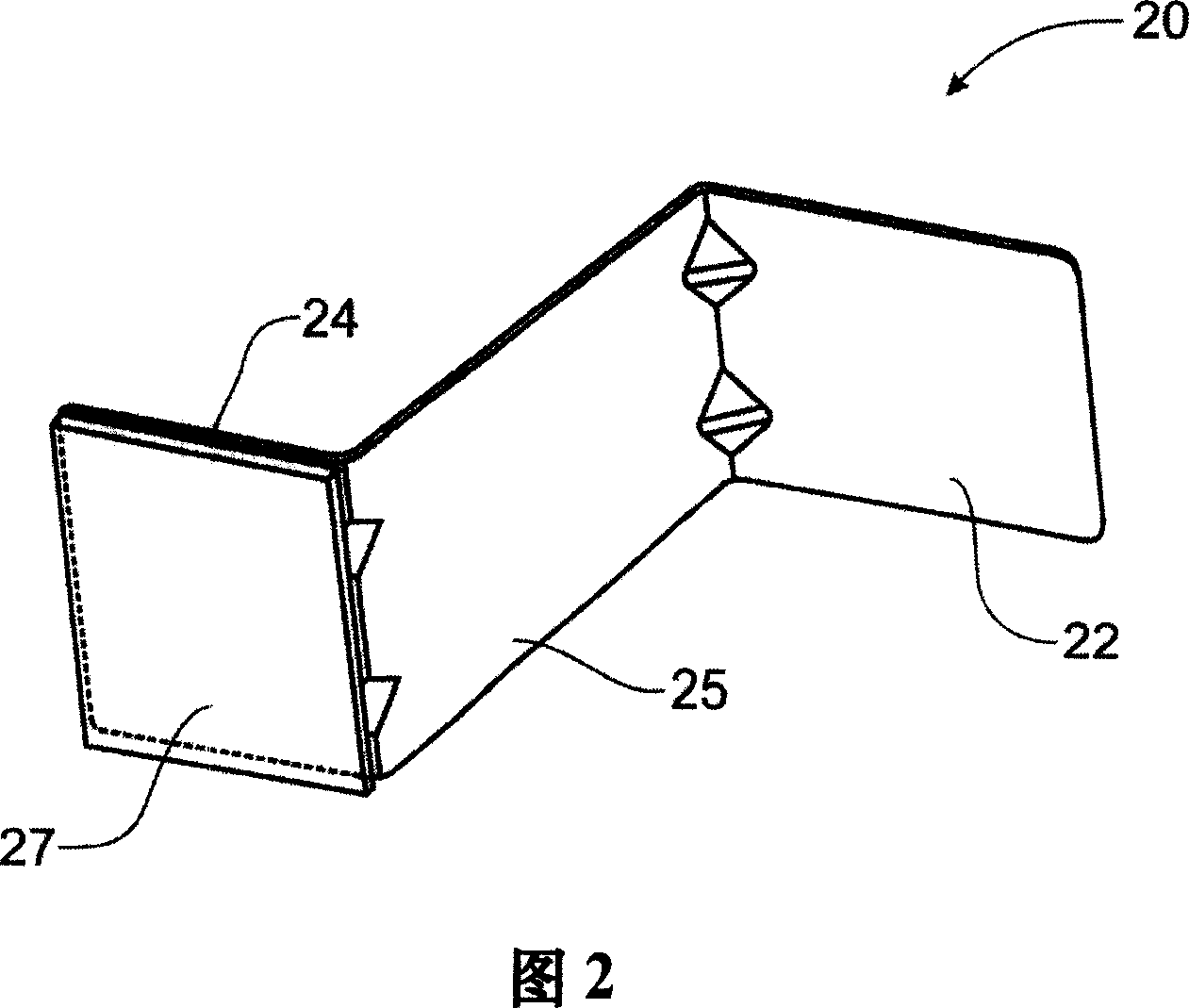

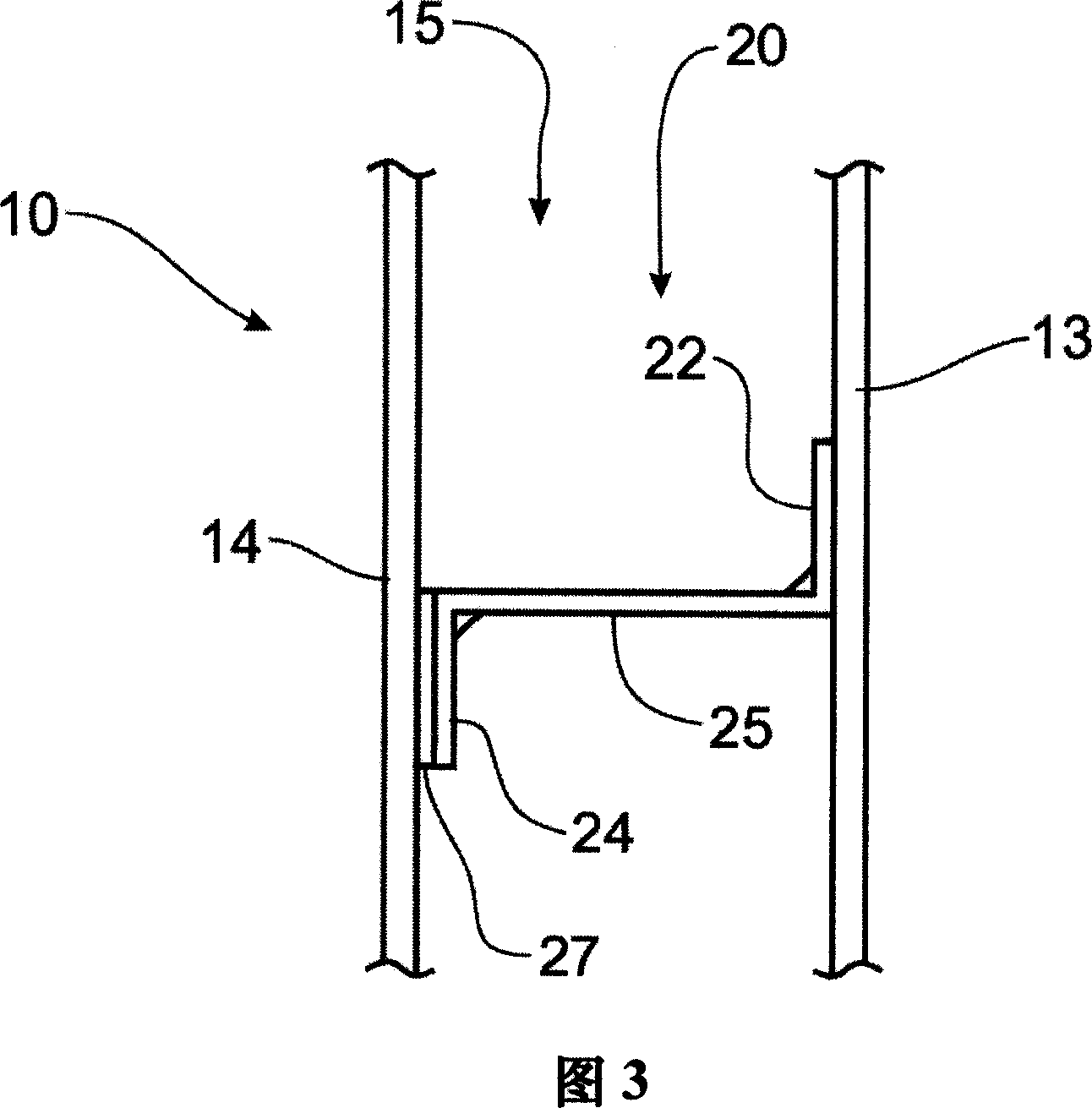

[0026] Referring to Figures 1-3, a rear panel subassembly embodying the principles of the present invention for a passenger compartment of a motor vehicle, such as a pickup truck, can be best seen. Those skilled in the art will readily recognize that the rear panel subassembly 10 is typically used as a rear structural component, positioned under the rear window glass of a pickup truck cab, as described by Steve Bruford. Bruford et al., US Patent Application No. 10 / 975,065, which is incorporated herein by reference. In some pick-up trucks or sports utility vehicles structured like a pick-up truck, the rear window 11 is fixed, or is arranged to slide sideways to selectively form a central opening in the rear window. In some rear panel subassemblies 10, as shown in FIG. In order to enable the rear window glass 11 to retract into the inner cavity 15, the middle part of the inner cavity 15 corresponding to the position of the rear window glass 11 must remain unobstructed.

[0027...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com