Moulding method and structure thereof of fabrics three-dimensional apical horn

A molding method and three-dimensional technology, applied in fabrics, textiles, textiles, and papermaking, can solve the problems of low processing efficiency, low production efficiency, and short service life, and achieve easy damage, convenient and fast processing, and extended use. The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

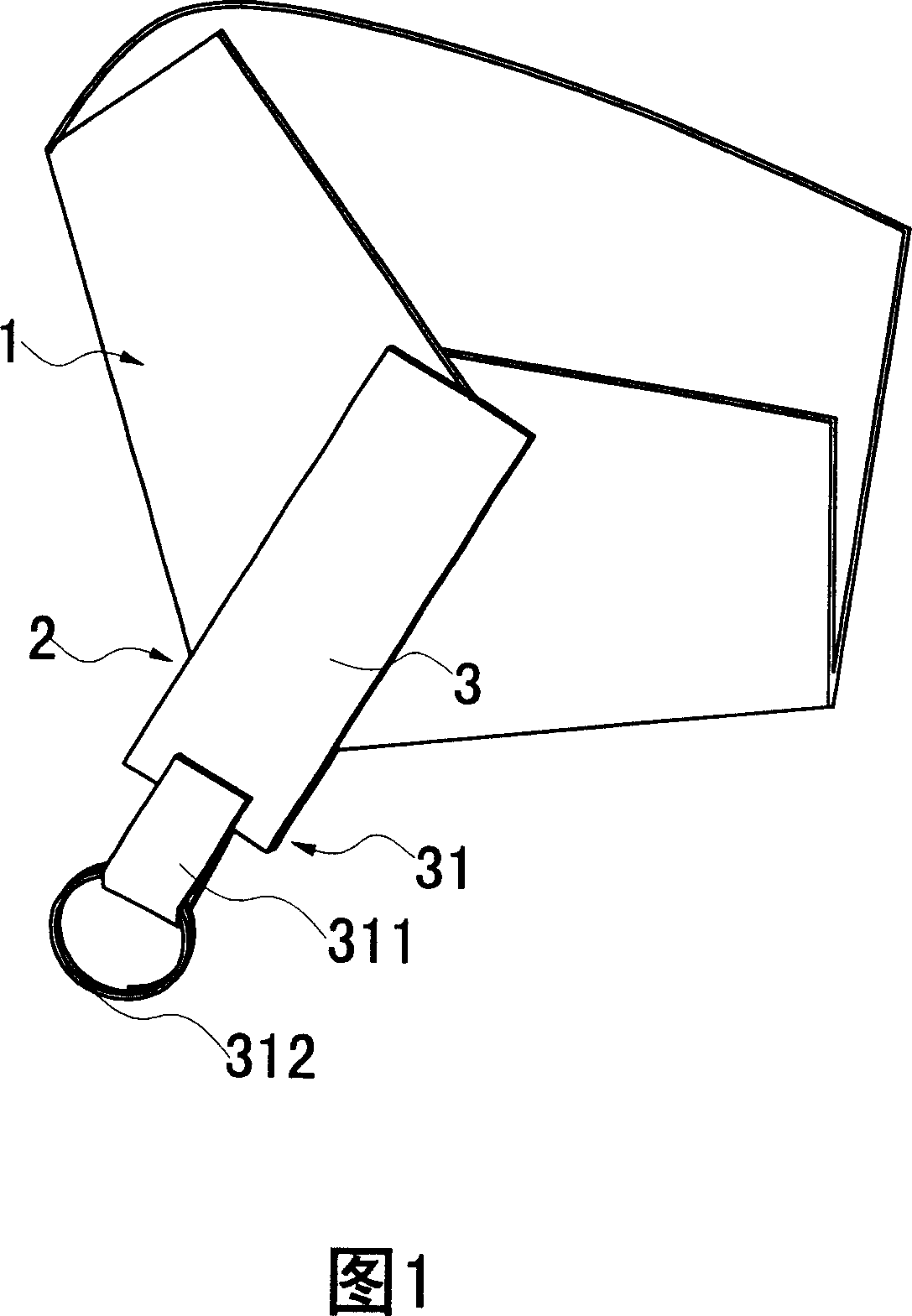

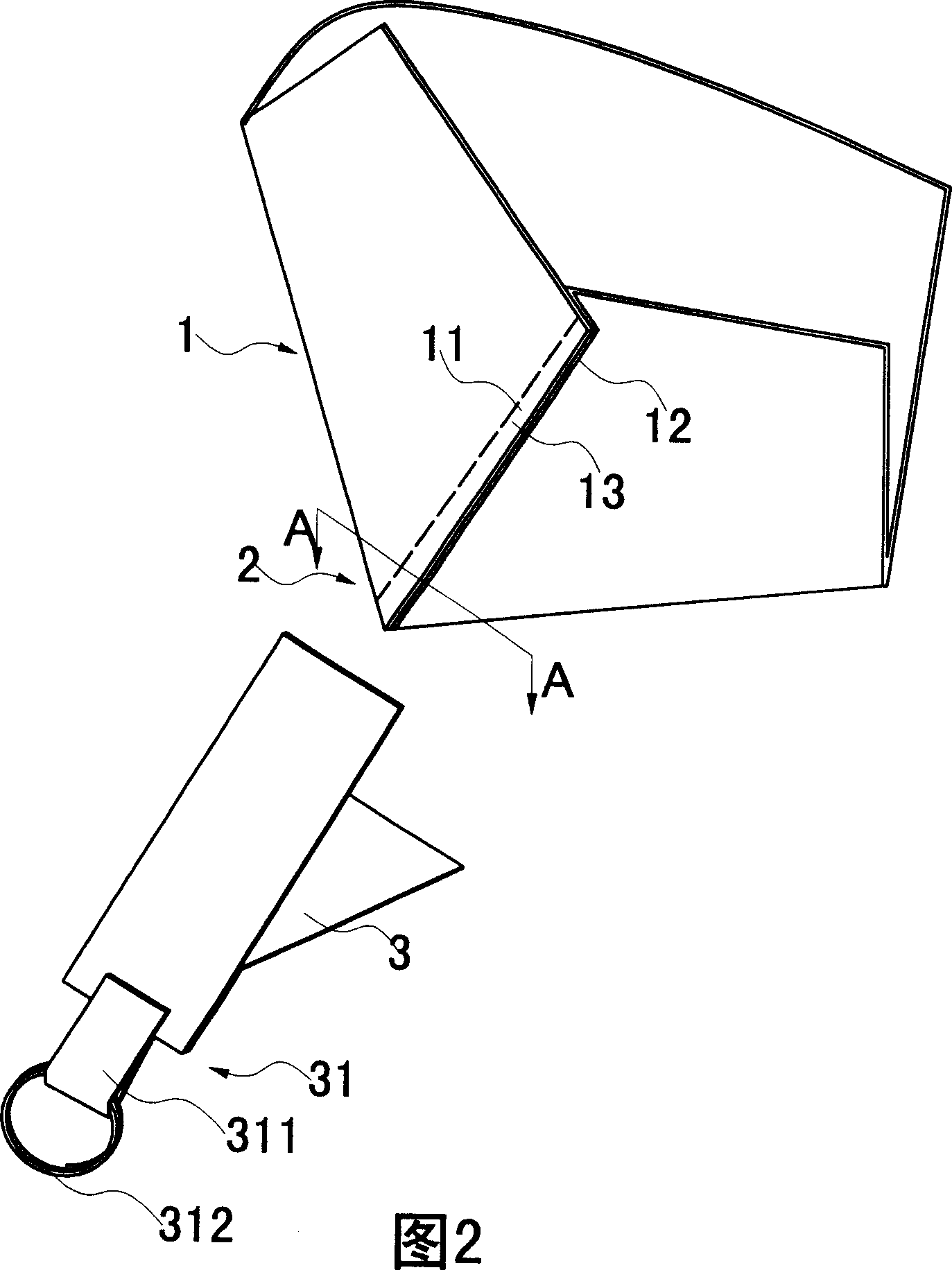

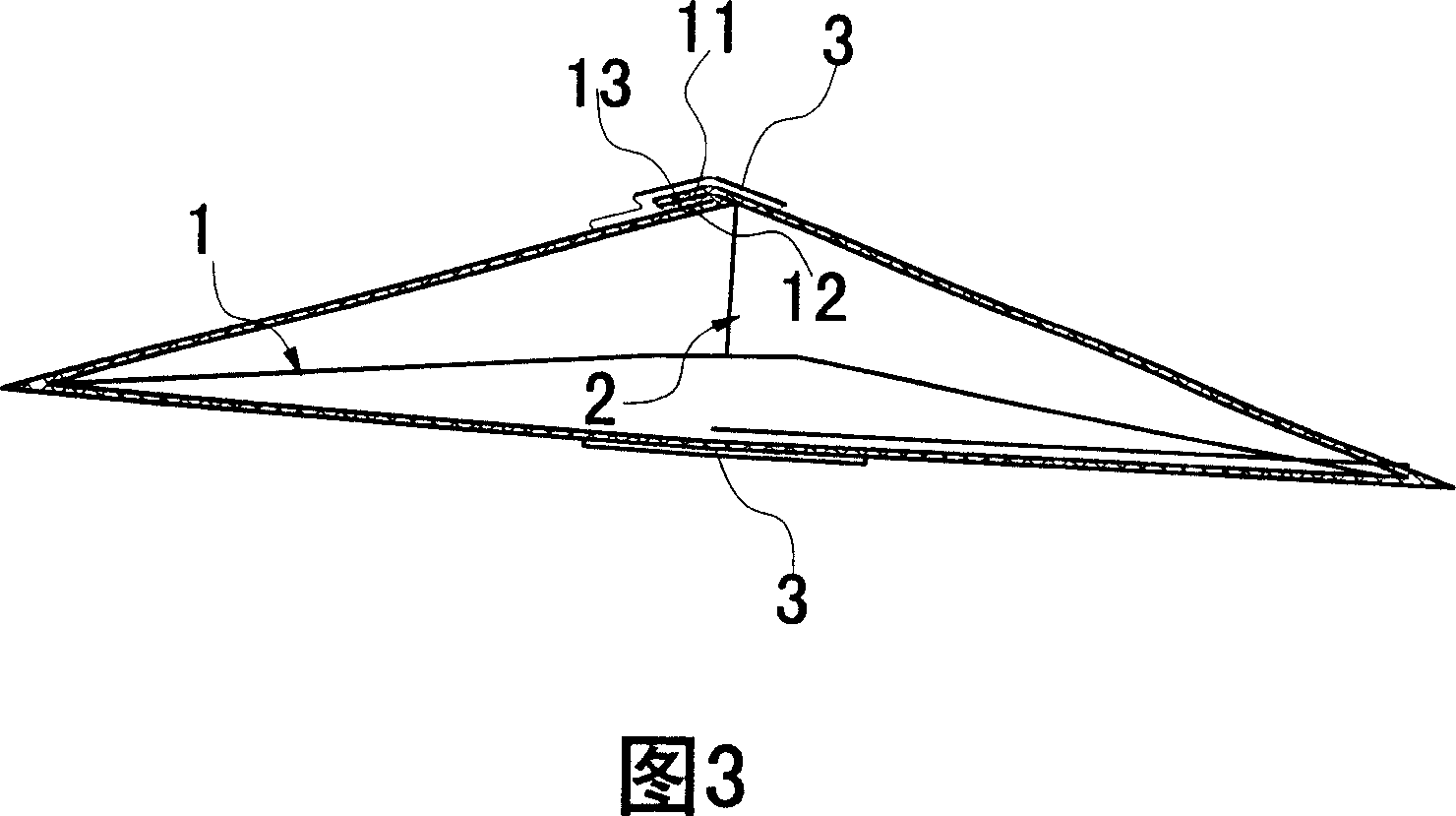

[0067] A kind of fabric three-dimensional vertex structure applied to tent cloth, as shown in Figures 1, 2, and 3, the fabric 1 has a first edge 11 and a second edge 12 that abut against each other, or bend the fabric 1 to make the fabric 1 is divided into a first edge 11 and a second edge 12. The fabric 1 is folded and its first edge 11 and second edge 12 are in contact and overlapped, and the overlapping edge 13 is sewn to form a three-dimensional corner 2, and two opposite outer sides of the three-dimensional corner 2 are welded or crimped or bonded Or heat-sewn waterproof cloth 3, the protruding parts of the two waterproof cloths 3 outside the central corner of the three-dimensional top corner 2 are directly welded or crimped or bonded or hot-sewn to form a joint 31, one of which is a waterproof cloth 3 directly covers all or part of the overlapping side 13 and seals the joint between the first edge 11 and the second edge 12, and the part of the overlapping side 13 is the ...

Embodiment 2

[0077] The difference between this embodiment and the previous embodiment is that, as shown in FIG. 5 , a coupling ring 312 is directly fixed on the coupling portion 31 .

Embodiment 3

[0079] The difference between this embodiment and the previous embodiment is that, as shown in Figure 6, the first edge 11 and the second edge 12 of the fabric 1 are only in contact with each other to form a three-dimensional corner 2 directly, without sewing. Connect the first edge 11 and the second edge 12. The corresponding first step in the forming method is: bending the fabric 1 so that the first edge 11 and the second edge 12 of the fabric 1 are in contact to directly form a three-dimensional corner 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com