Light shield and method for forming air-cushion surface pattern on surface of magnetic head using same

An air cushion surface and photomask technology, which is applied to the hydrodynamic spacing of the head, the configuration/installation of the recording head, the support head, etc., can solve the problem that the gap between the long strips cannot be shortened sufficiently, the production efficiency of the lithography machine cannot be improved, and the long-term The number of strips cannot be increased, etc., to achieve the effects of increasing the output of magnetic heads, saving materials, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

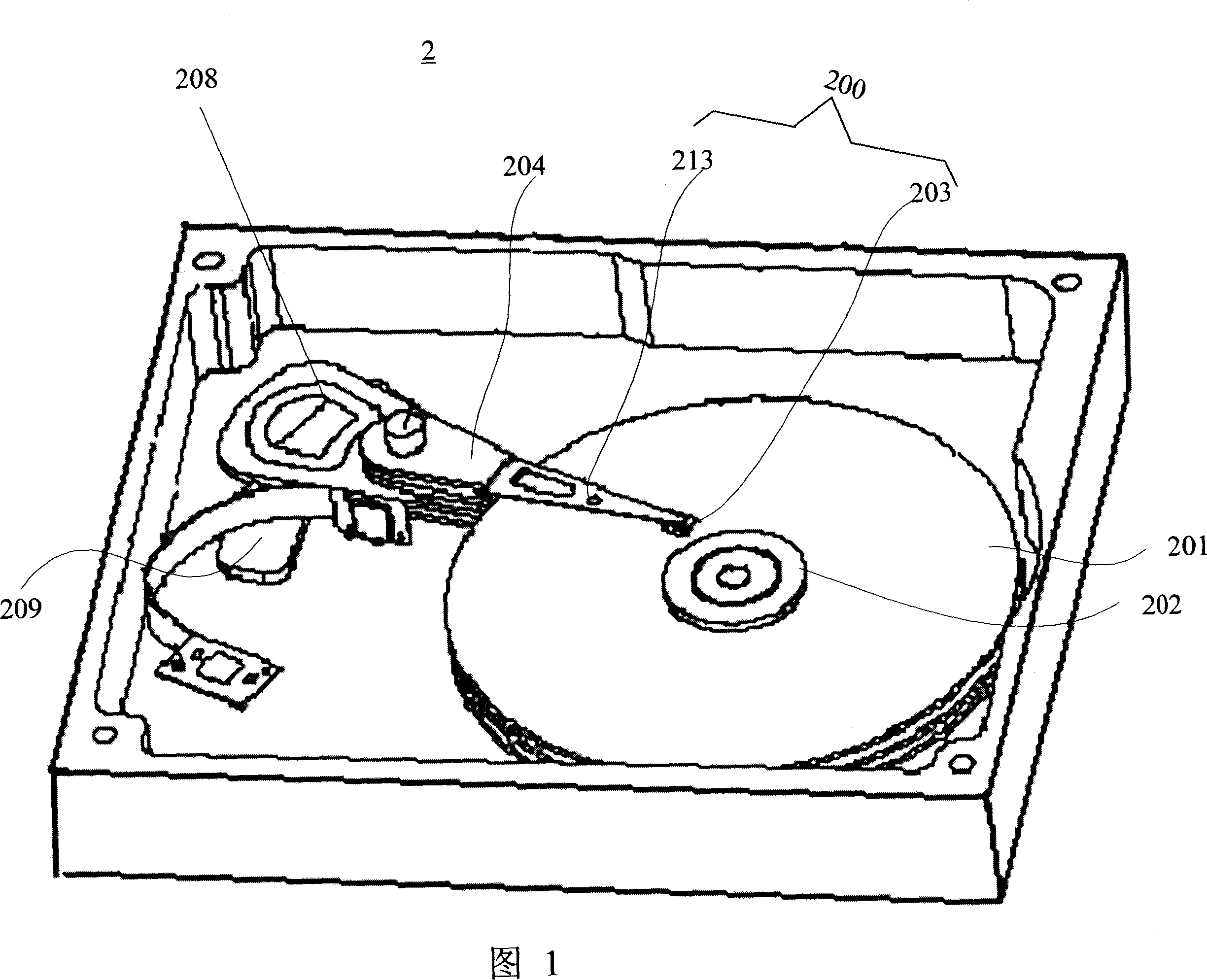

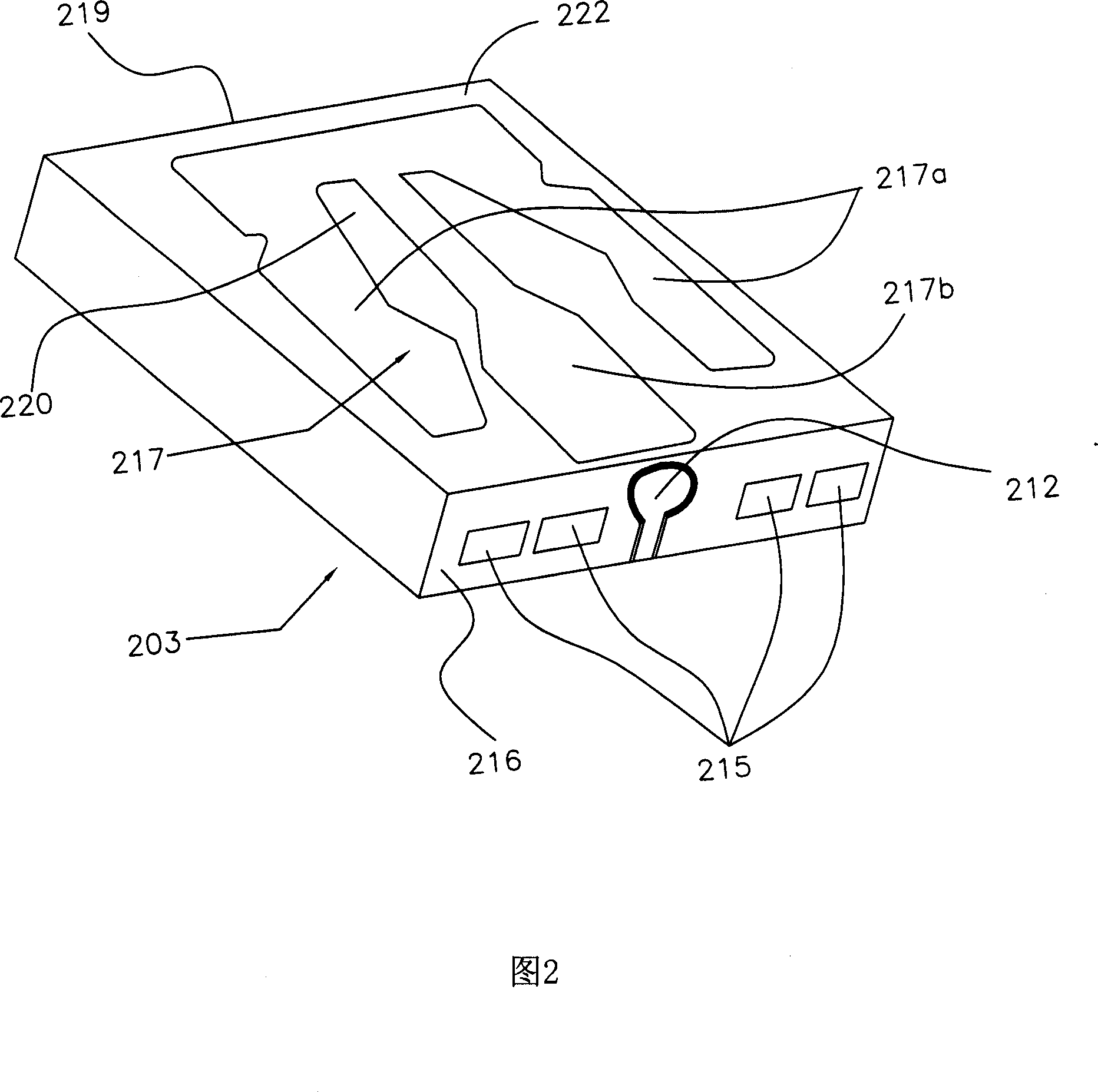

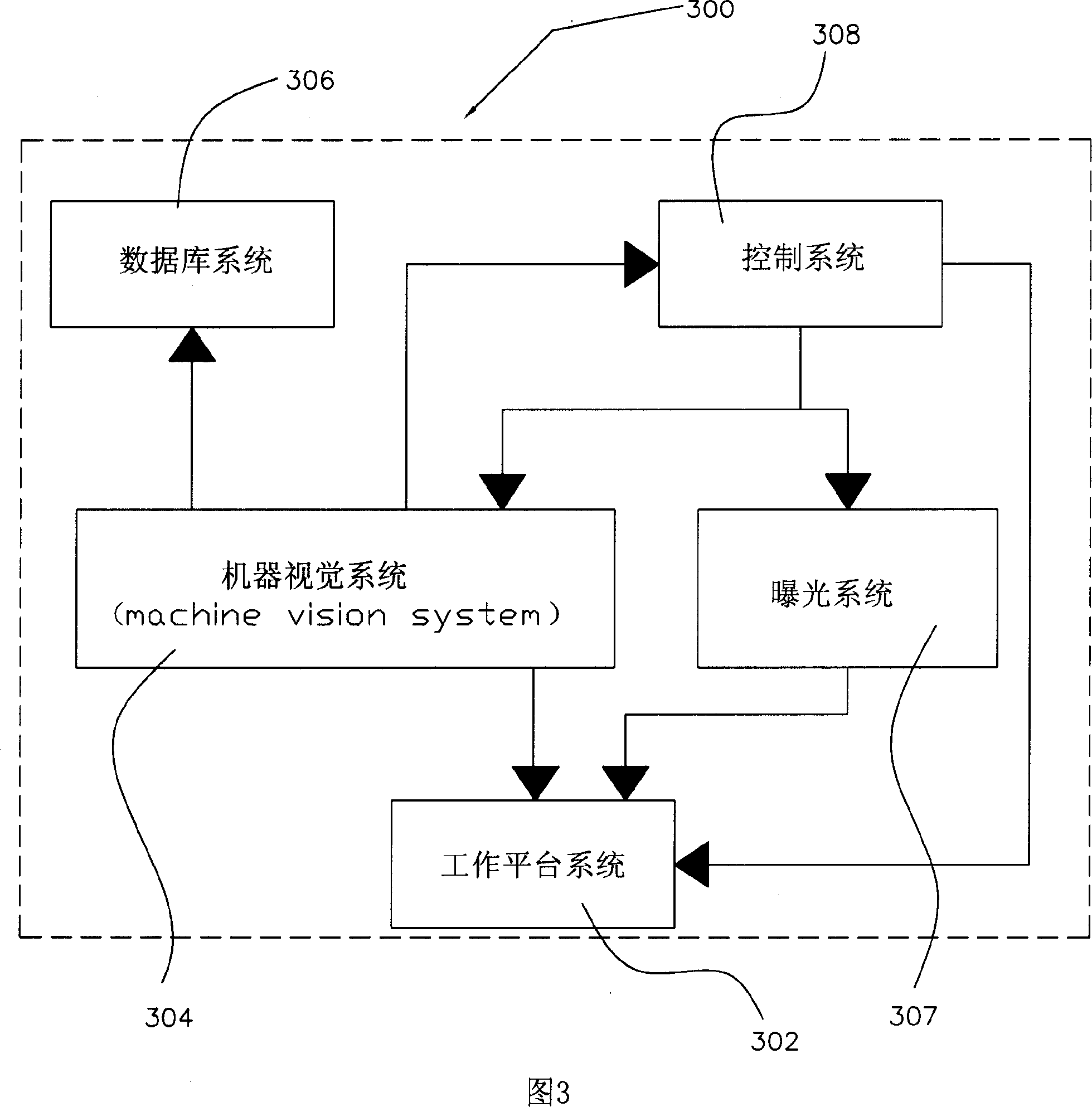

[0047] Embodiments of the present invention will now be described with reference to the accompanying drawings. The invention provides a photomask, comprising: a base and a metal thin film layer formed on the base. An air bearing surface image, a mask mark and a machine vision system window are formed on the metal thin film layer. Wherein, the window of the machine vision system is coincident with the image of the air bearing surface. The invention uses the light-transmitting central air-bearing surface image with a large outline on the reticle as the window of the machine vision system, avoiding the design of the machine vision system window with a small outline that exists independently in the traditional reticle, and at the same time forming a small size on the reticle. The reticle logo of the reticle replaces the oversized reticle logo in the traditional reticle. Through the cooperation between the window of the machine vision system and the reticle mark, the long strip c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com