Dc-to-dc converter and electric motor drive system using the same

A technology of DC converter and converter, which is applied in the direction of DC motor speed/torque control, conversion of DC power input to DC power output, control system, etc., and can solve the problems of increased manufacturing cost and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

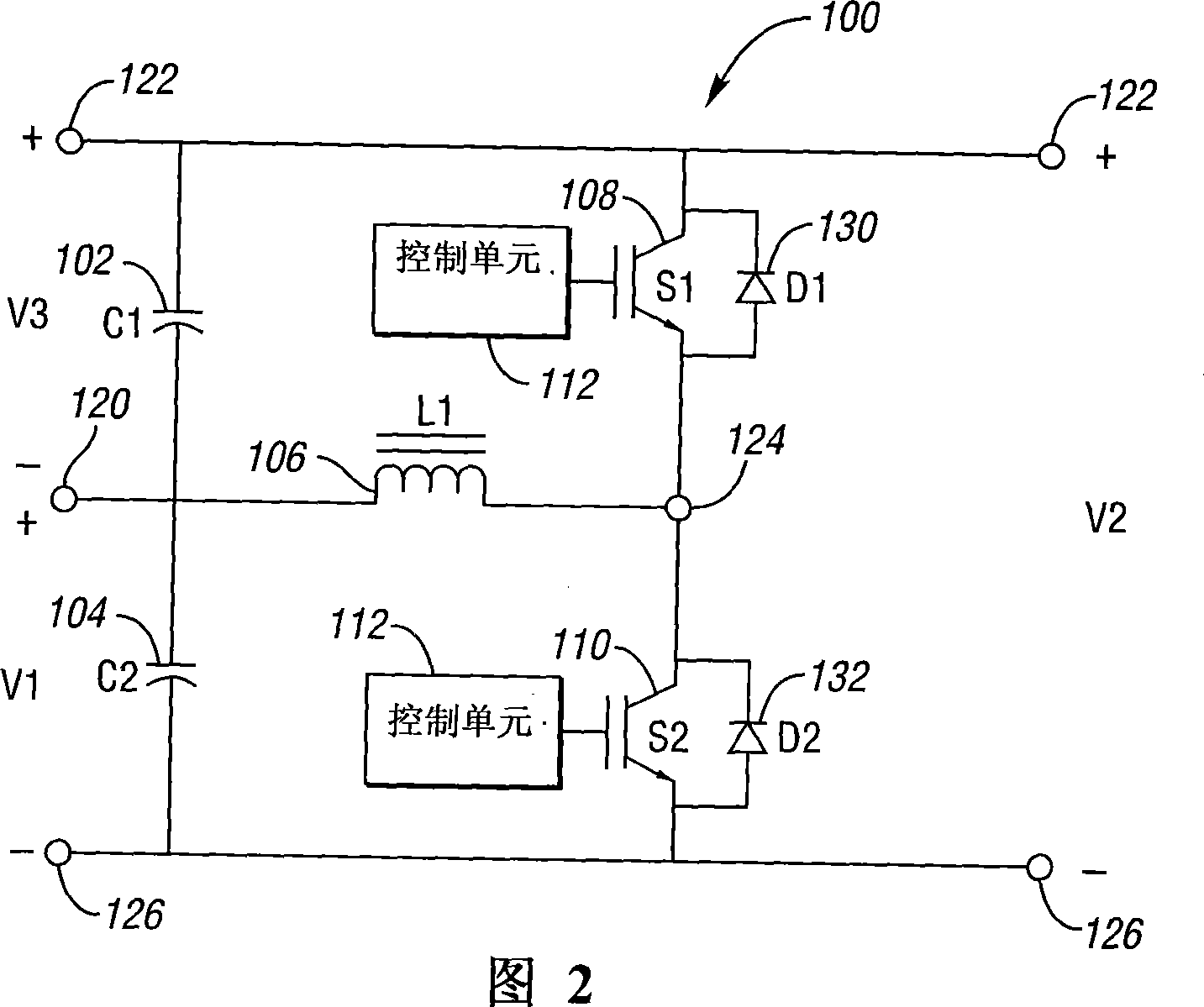

[0015] Referring to FIG. 2 , it shows a schematic diagram of a DC-DC converter 100 according to at least one embodiment of the present invention. The converter 100 generally comprises a first capacitor (ie C1) 102, a second capacitor (ie C2) 104, an inductor (ie L1) 106, a first switching device (ie S1) 108, a second switching device (ie S2 ) 110, and a plurality of nodes, such as a first node 120, a second node 122, a third node 124, and a fourth node 126.

[0016] First capacitor 102 (i.e., capacitive element), second capacitor 104, and inductor 106 (i.e., inductive element) may each include a circuit breaker for connecting the respective component (i.e., 102, 104, and / or 106) to an adjacent component. first and second terminals (ie, electrical connection points). Likewise, the first 108 and / or second 110 switching devices (ie, switches) may each include first and second terminals connecting the respective switches (ie, 108 and / or 110 ) to adjacent components.

[0017] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com