Egr control device for internal combustion engine

A technology for control devices and internal combustion engines, applied in engine control, internal combustion piston engines, electrical control, etc., can solve difficult problems such as system simplification and matching difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

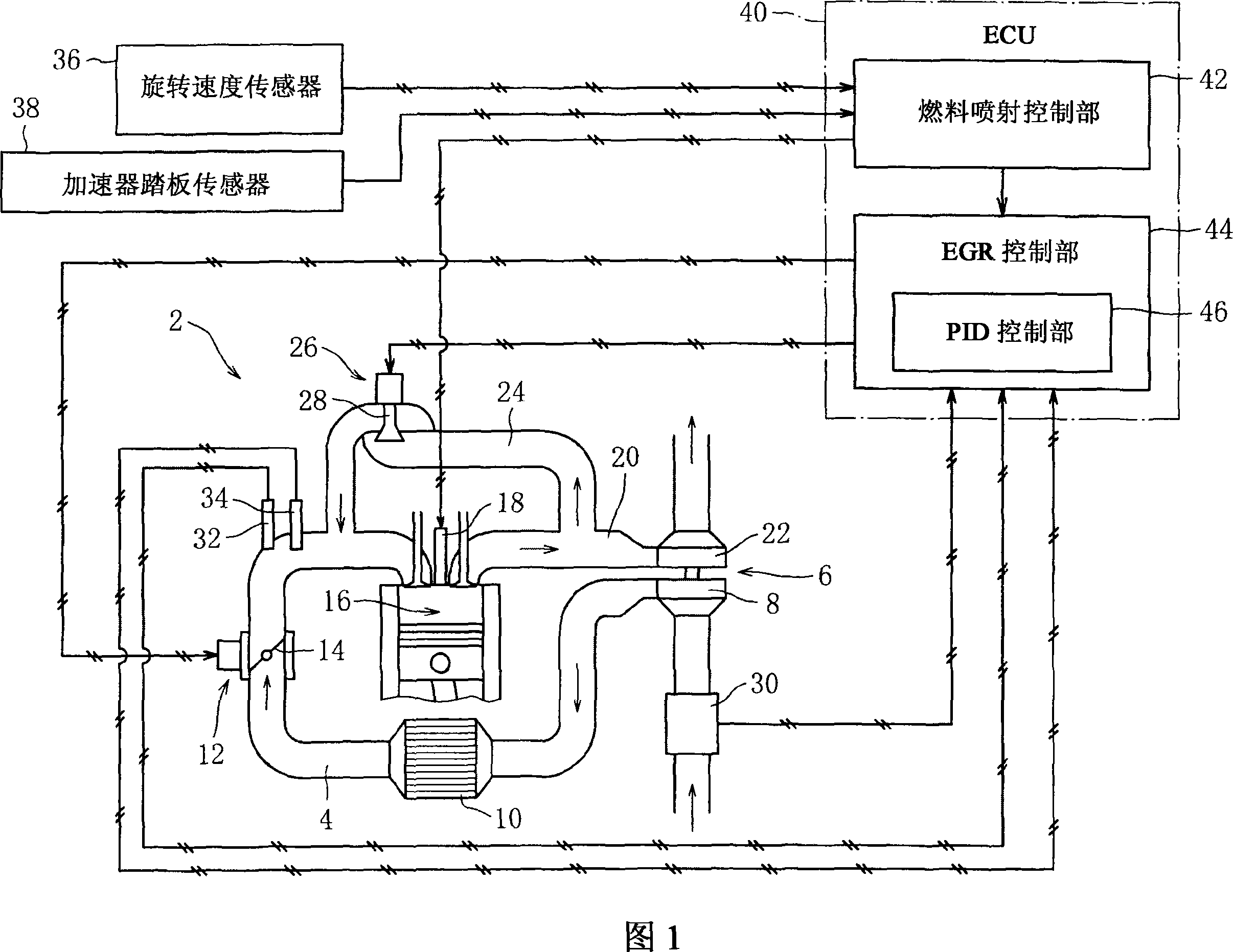

[0015] Embodiments of the present invention will be described below with reference to the drawings.

[0016] Fig. 1 is an embodiment of an EGR control device for a diesel engine. As shown in the figure, a supercharger 6 is provided in the intake passage 4 of the engine 2 . Intake air taken from an air cleaner (not shown) is pressurized by compressor 8 and introduced into combustion chamber 16 via intercooler 10 .

[0017] In addition, an intake throttle valve 12 is provided at an appropriate position in the passage 4 . The throttle valve 12 has a butterfly valve body 14 driven by a brushed motor, and the flow rate of the intake air is controlled by the opening and closing of the valve body 14, and the recirculation amount of the exhaust gas (EGR) as described later is also controlled. quantity). In this way, in the throttle valve 12 of the present embodiment, a current flows in a diagram in which a magnetic field is generated using a brush.

[0018] A turbine 22 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com