Pneumatic flexible torsional knuckle

A flexible and joint technology, applied in the direction of manipulators, manufacturing tools, joints, etc., can solve the problems of unreasonable robot joint structure, difficulty in miniaturization, poor flexibility, etc., and achieve the effect of high implementation value, easy miniaturization, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

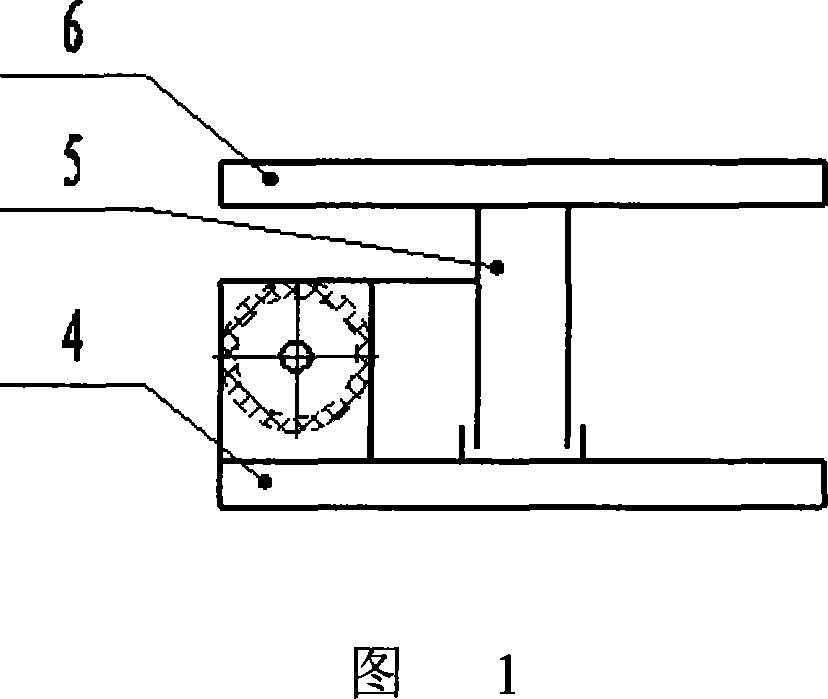

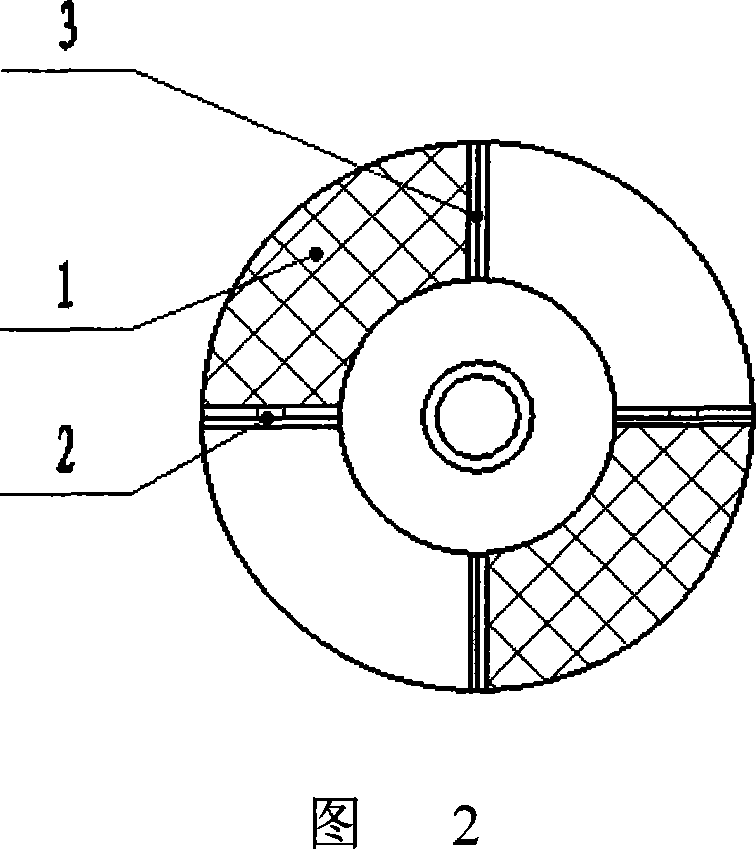

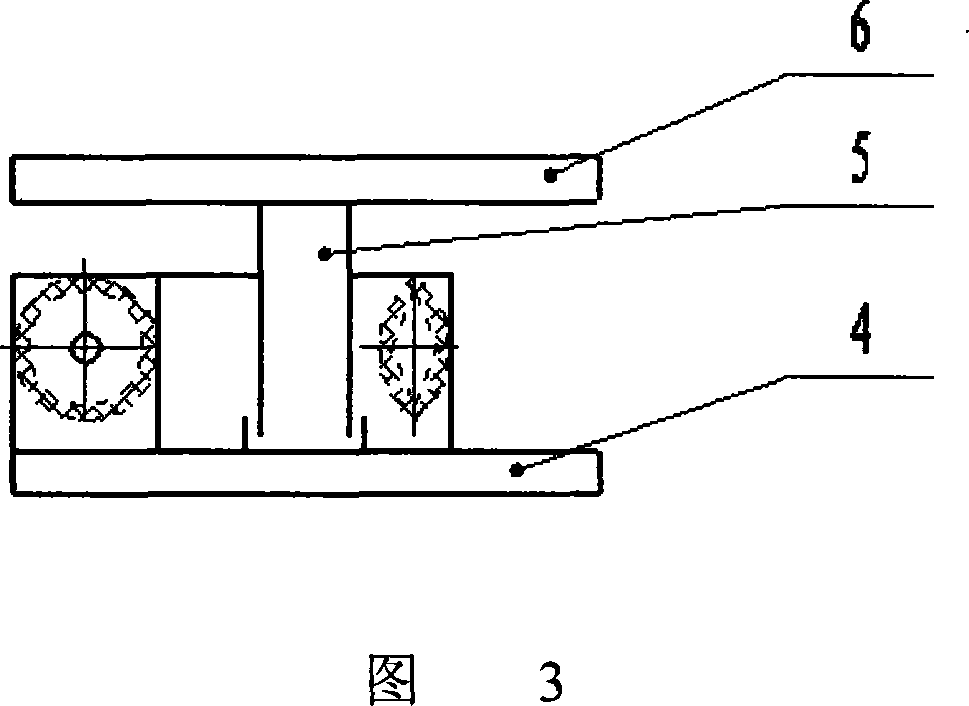

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] Referring to Figures 1 to 4, a pneumatic flexible torsion joint is composed of an arc-shaped pneumatic flexible cylinder 1, a first end cover 2, a second end cover 3, a fixed disc 4, a central shaft 5 and a circular turntable 6, and the arc The left and right ends of the shaped pneumatic flexible cylinder 1 are respectively connected with the first end cover 2 and the second end cover 3. Due to its inherent arc shape, the arc-shaped pneumatic flexible cylinder can ensure that it can elongate along the arc during rotation. or contraction; the first end cover 2 has a through hole to communicate with the outside atmosphere, and one end of the second end cover 3 is closed, and two arc-shaped pneumatic flexible cylinders 1 of the same size are symmetrically placed on the fixed disk 4 left and right in the center, and the fixed disk 4 is equipped with a central axis 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com