Construction method for guiding slurry and pulling pipe

A construction method, a technology of grout-guiding and pipe-drawing, which is applied in the sewer pipeline system, waterway system, water supply device, etc., can solve the problems of heavy reaming workload, large disturbance of surrounding soil, cracking of houses, etc., and achieve accurate elevation control, It is not easy for the house to crack and the effect of ground subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

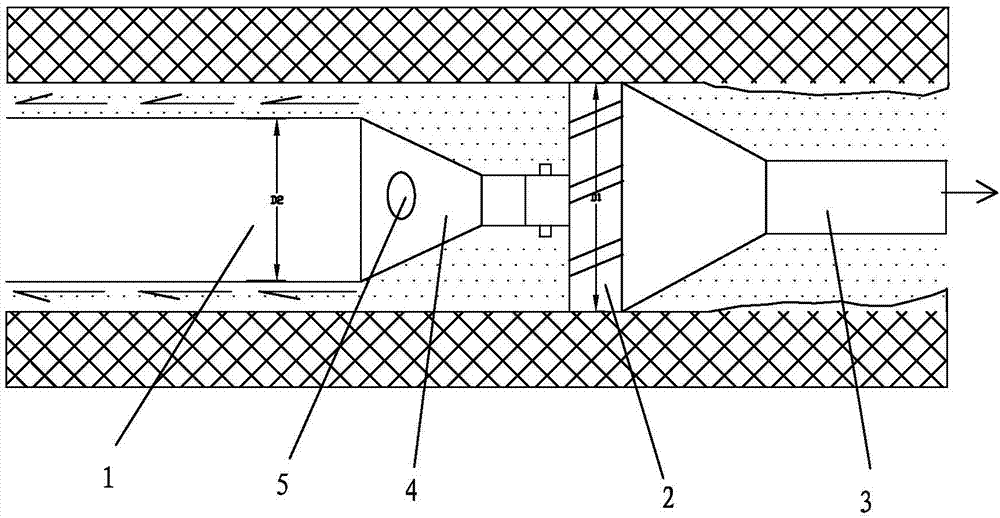

[0030] Such as figure 1 Shown, a kind of construction method of grout drawing pipe comprises the following steps:

[0031] A. Connect the top of the reaming drill 2 with the guide drill rod 3, and connect the tail of the reaming drill 2 with the pipeline 1;

[0032] B. The guide drill rod 3 is aligned to the position to be constructed, the reaming drill bit 2 is started, the guide drill rod 3 is guided, the reamer drill bit 2 cuts the soil and discharges the mud into the pipeline 1, and the drill hole is expanded to the hole at one time size;

[0033] C. After the pipe drawing is completed, the reaming bit 2 is separated from the pipe, and the mud in the pipe 1 is discharged, and the pipe 1 remains in the hole.

[0034] The construction method of the present invention is to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com