Turnover device

A technology of flipping device and flipping plate, applied in the direction of assembly machine, magnetic recording, record carrier structural parts, etc., can solve the problems of inconvenience in accurate positioning and installation of belts, difficulty in accurately positioning and installing magnetic sheets, and low installation efficiency, and achieves The effect of convenient operation, high work efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

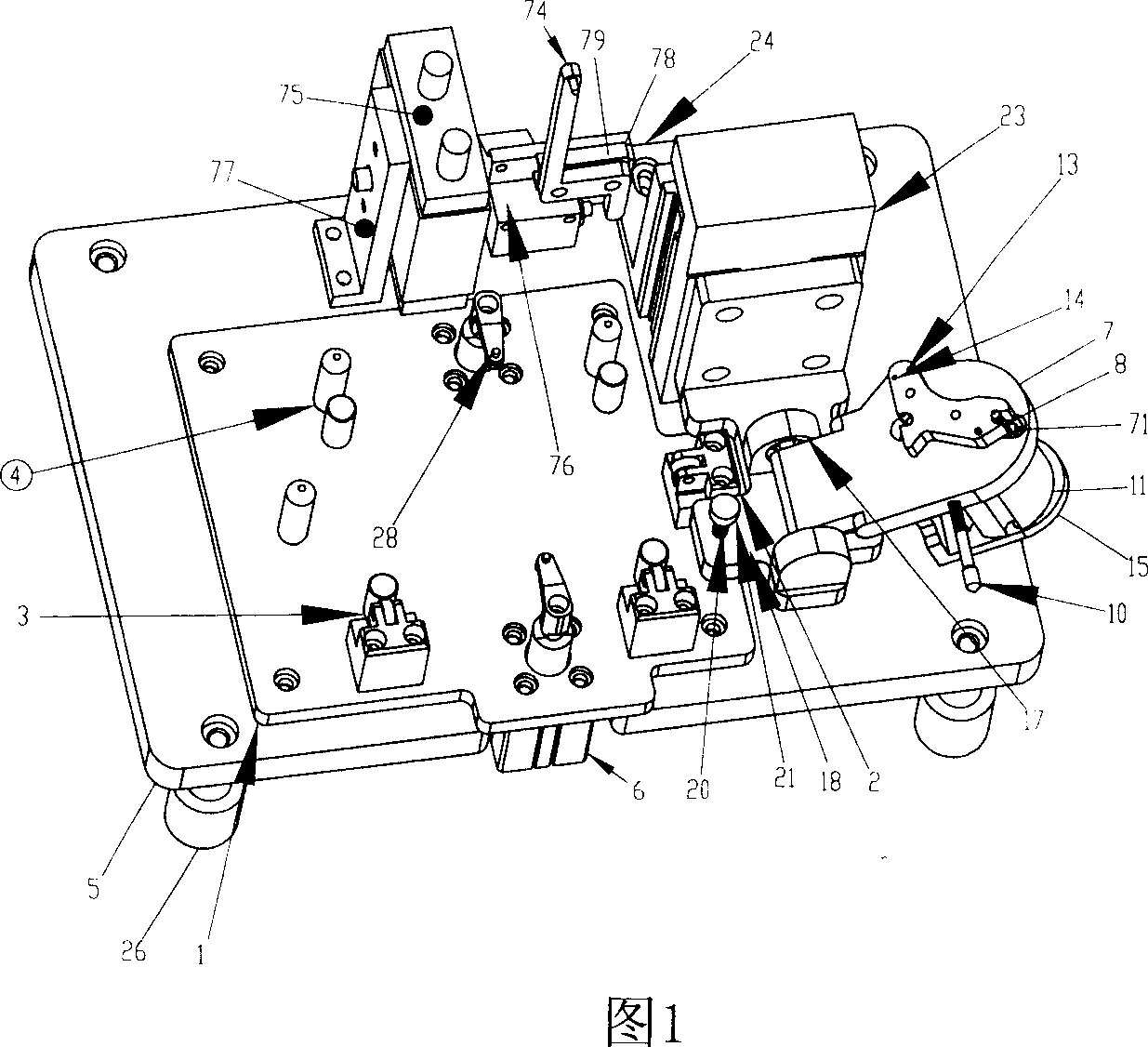

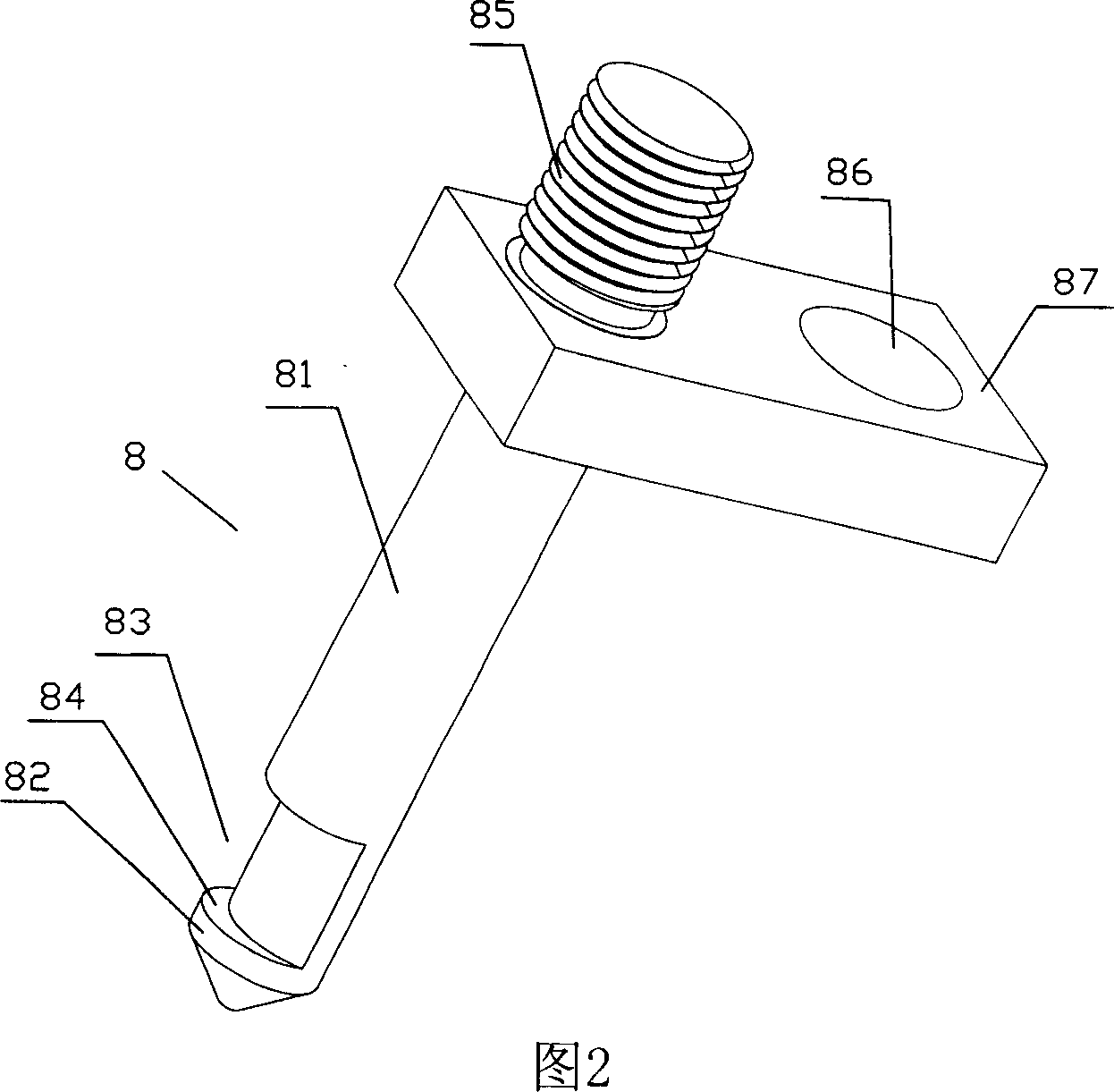

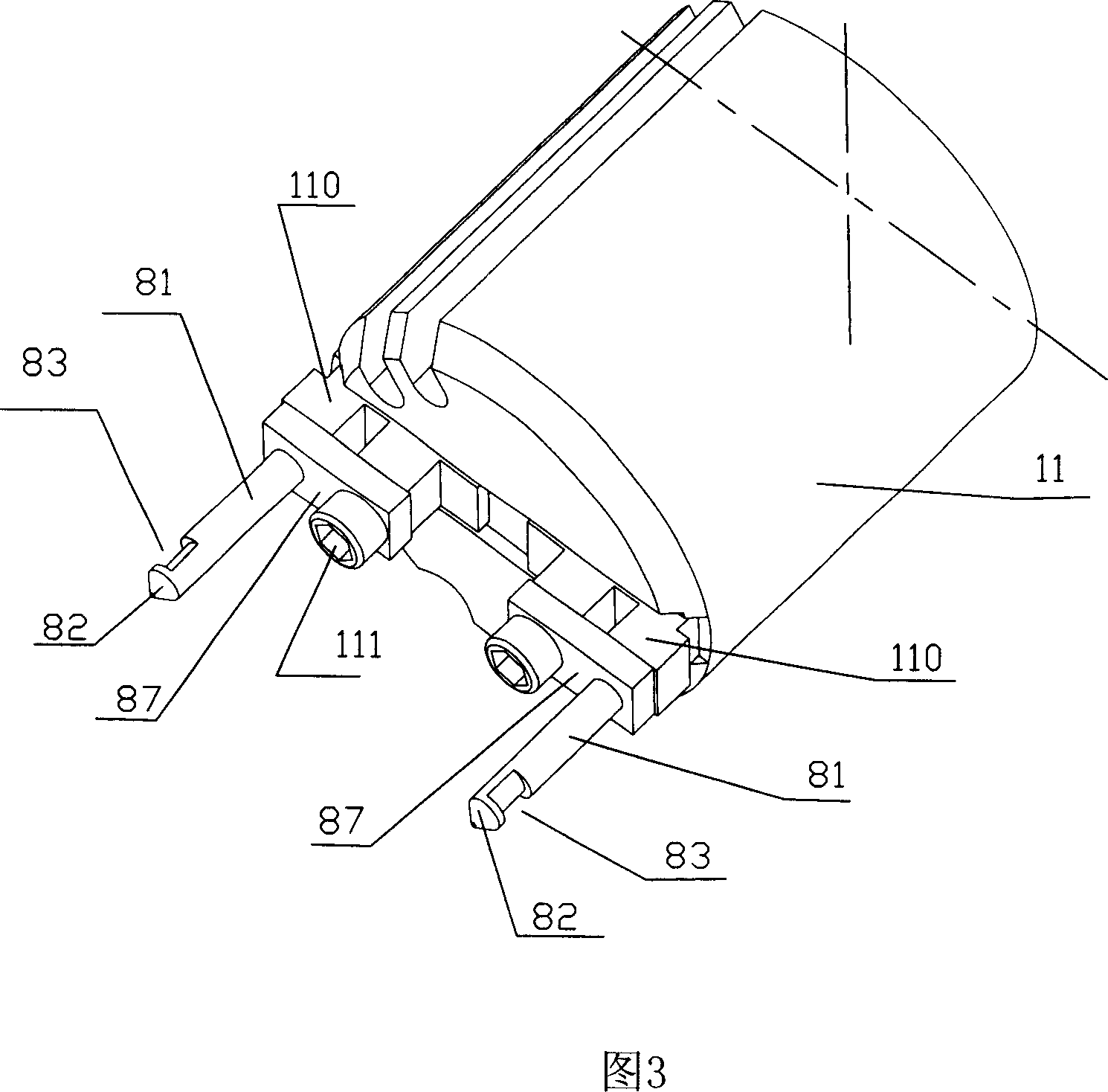

[0027] A flipping device, as shown in Figure 1, Figure 2 and Figure 3, includes a clamping device, a base plate 5, a tooling panel 1 fixed on the base plate 5, and a displacement adjustment device. The lifting cylinder 23 on the bottom plate 5 , the turning plate seat 17 fixedly connected with the lifting cylinder 23 , the turning plate 7 rotatably supported on the turning plate seat 17 , and the turning regulating plate 18 fixedly connected with the turning plate seat 17 . At least a pair of positioning holes 71 are formed on the flip plate 7, and a clamping claw 8 protrudes from each positioning hole 71. The clamping claw 8 includes a clamping rod 81 and a fixing block 87, and the top of the clamping rod 81 has a clamping head 82. The clamping head There is an arc-shaped notch 83 on the 82, and a boss 84 supporting the clamping part is formed under the arc-shaped notch 83 near the top. The part of the block 87 is a threaded rod 85, and the fixed block 87 has a sleeve 86 ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com