Pressurized water reactor nuclear power station control bar driving mechanism on-line monitoring and fault diagnosing method

A technology of pressurized water reactor nuclear power plant and driving mechanism, which is applied in nuclear power generation, reactor, nuclear engineering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

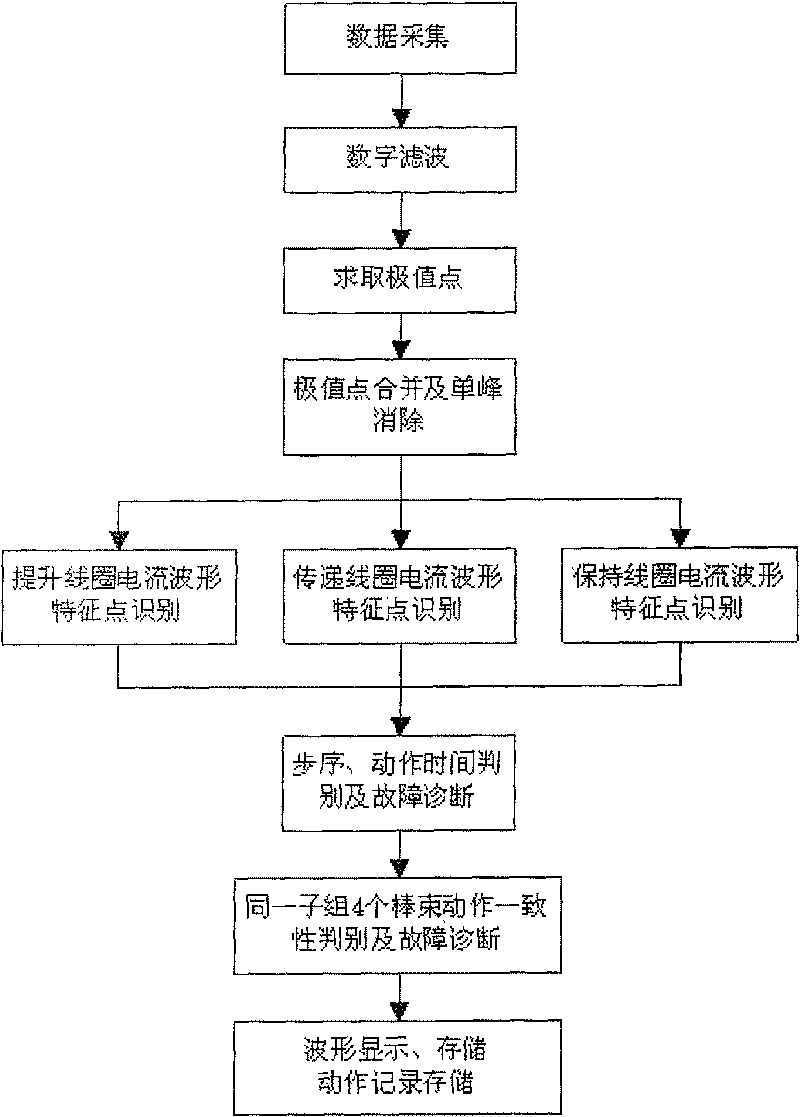

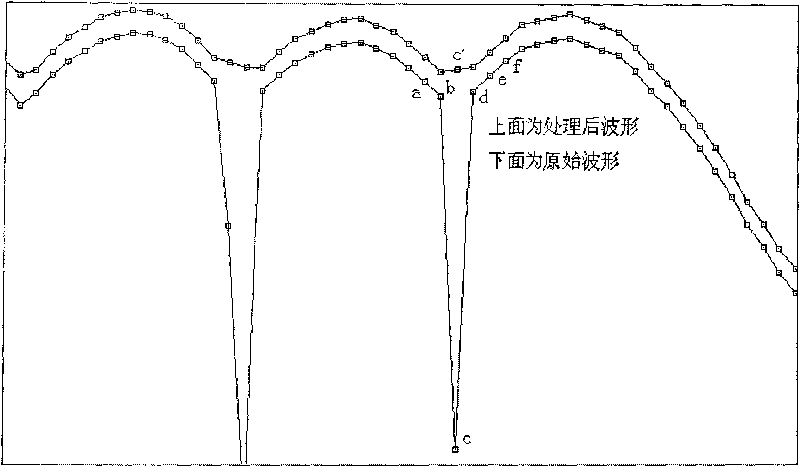

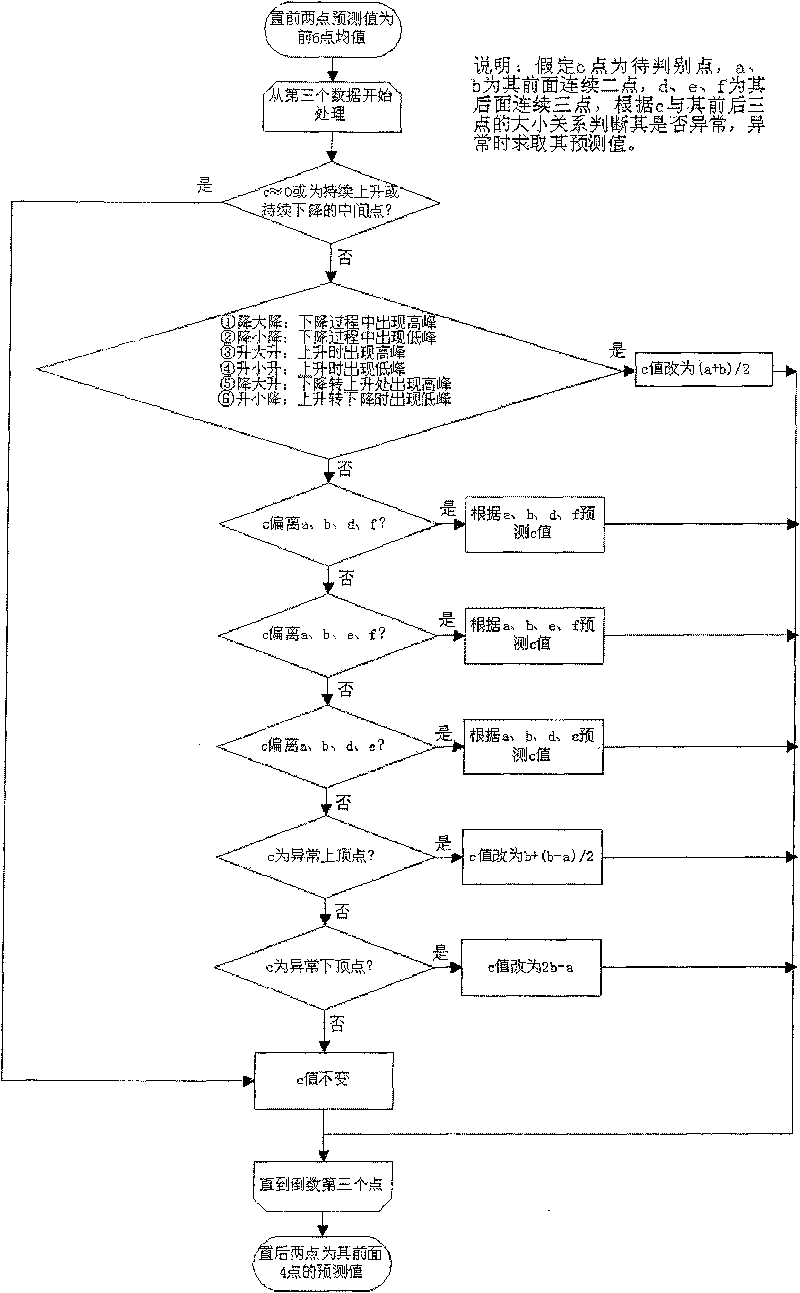

Method used

Image

Examples

Embodiment Construction

[0080] There are 33 bundles of control rods for Qinshan Phase II Reactor. 8 shutdown rod bundles and 25 regulation rod bundles are used to adjust the power of the reactor. Eight shutdown rod bundles are compiled into a rod group——Sa, and Sa is divided into two subgroups, Sa1 and Sa2, and each subgroup contains 4 rod bundles. The 25 adjustment rod bundles are compiled into four rod groups A, B, C and D, and the three rod groups A, B and C are divided into two subgroups 1 and 2 respectively; A1, A2, B1, B2, C1 and D each Contains 4 bundles, C2 only contains 1 bundle. Correspondingly, there are 33 control rod drive mechanisms, and each subgroup is controlled by a power cabinet, a total of 9 power cabinets.

[0081] Each driving mechanism has 3 coils, and 3 current signals need to be measured. If the sound and vibration signals for judging the movement of the mechanism are added, each driving mechanism has 4 signals to be collected. 132 signals need to be collected for 33 drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com