Digging-drilling integrated digging-drilling machine

A technology of excavation and drilling rigs, which is applied in the field of excavation and drilling integrated new models - excavation and drilling rigs, which can solve problems such as the limitation of excavation space, the limitation of drilling range, and the complexity of hydraulic systems, so as to reduce the space size and improve work efficiency. , The effect of simplifying the design structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

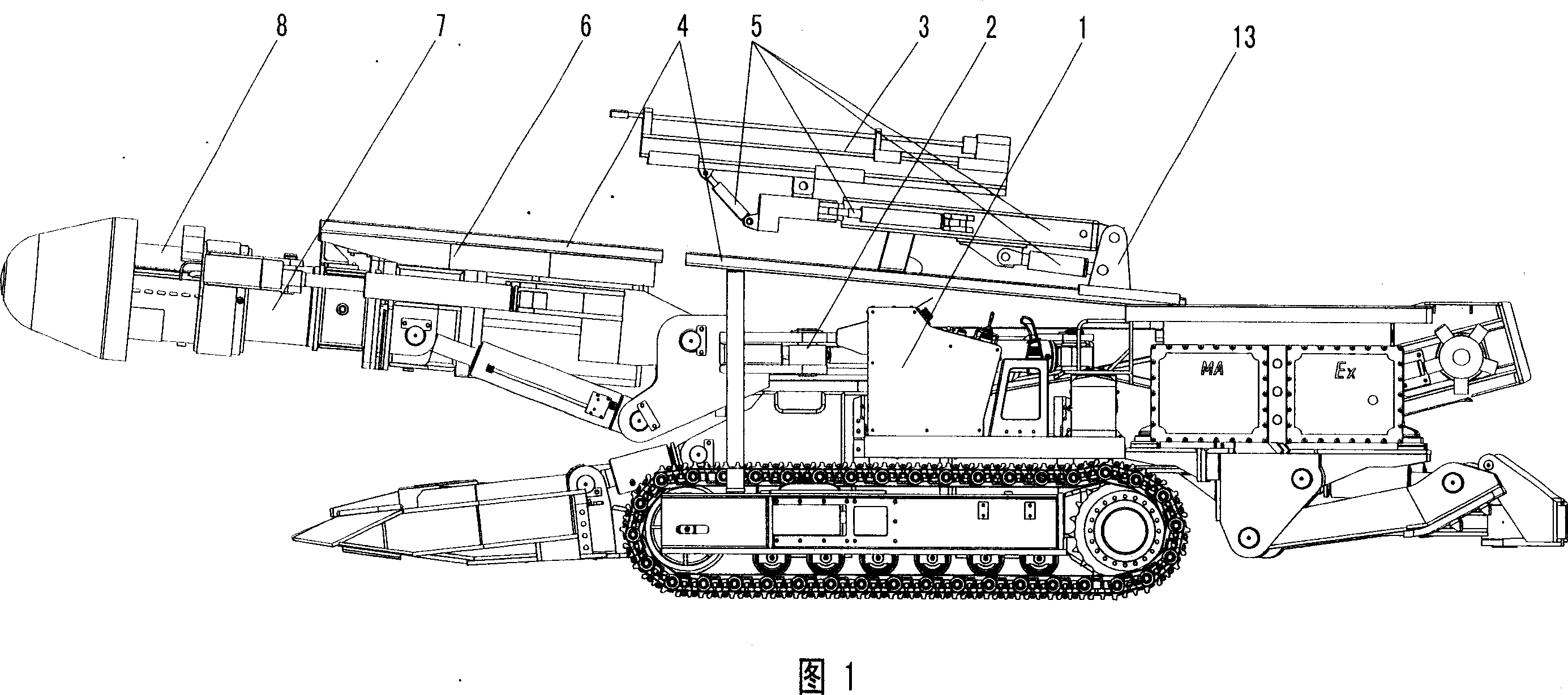

[0023] As shown in Fig. 1, the present invention is an excavation and drilling integrated excavation and drilling machine. The rooms are connected by track 4. The above part of roadheader 1 among the figure is exactly drilling machine 3 devices. It moves up and down and swings together with the cutting part 7 of the roadheader 1 and the rotary table 2, together with the hydraulic cylinder 5 of the drilling machine 3 (including: angle adjustment cylinder 9, telescopic cylinder 10, swing cylinder 11, support lifting cylinder 12) With its own function, the drilling work of the deep hole in the roadway can be completed.

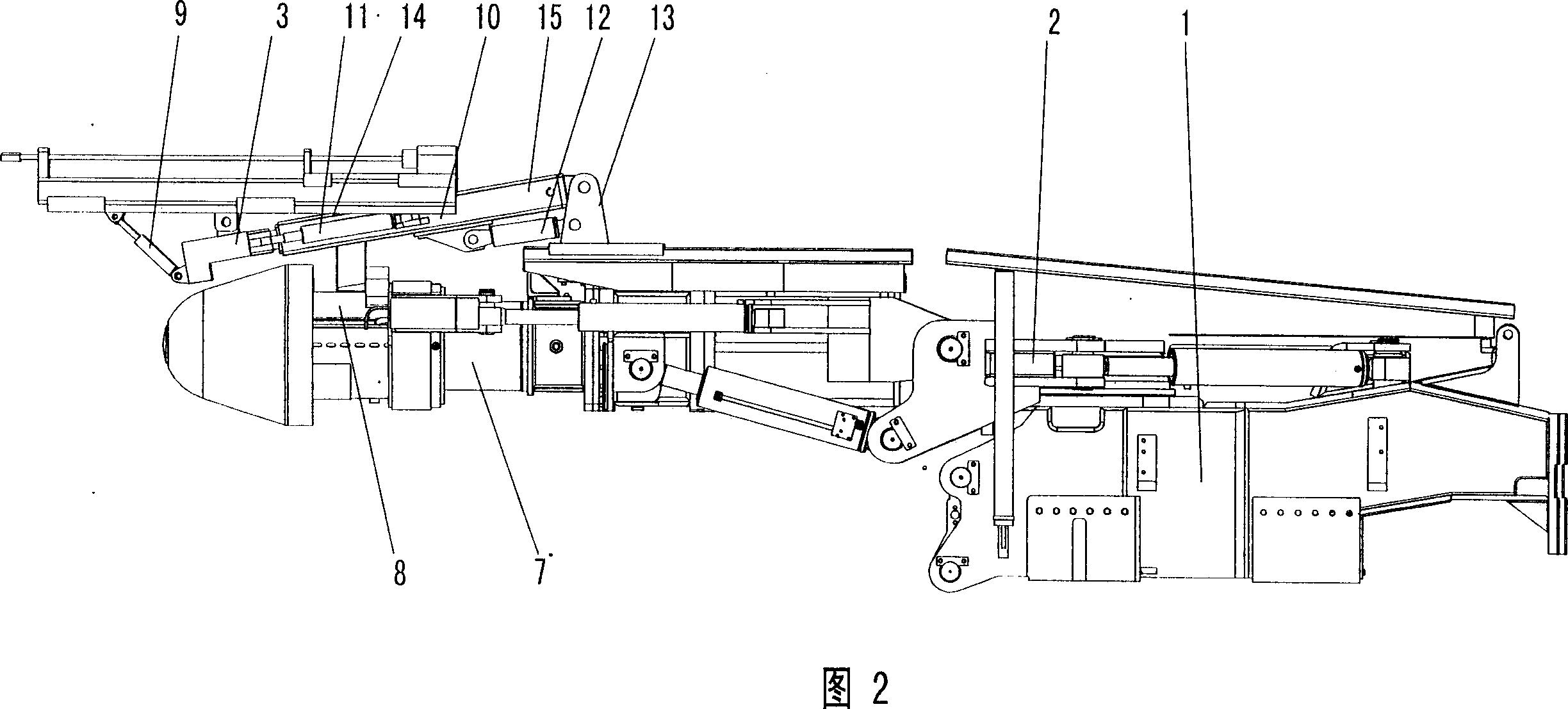

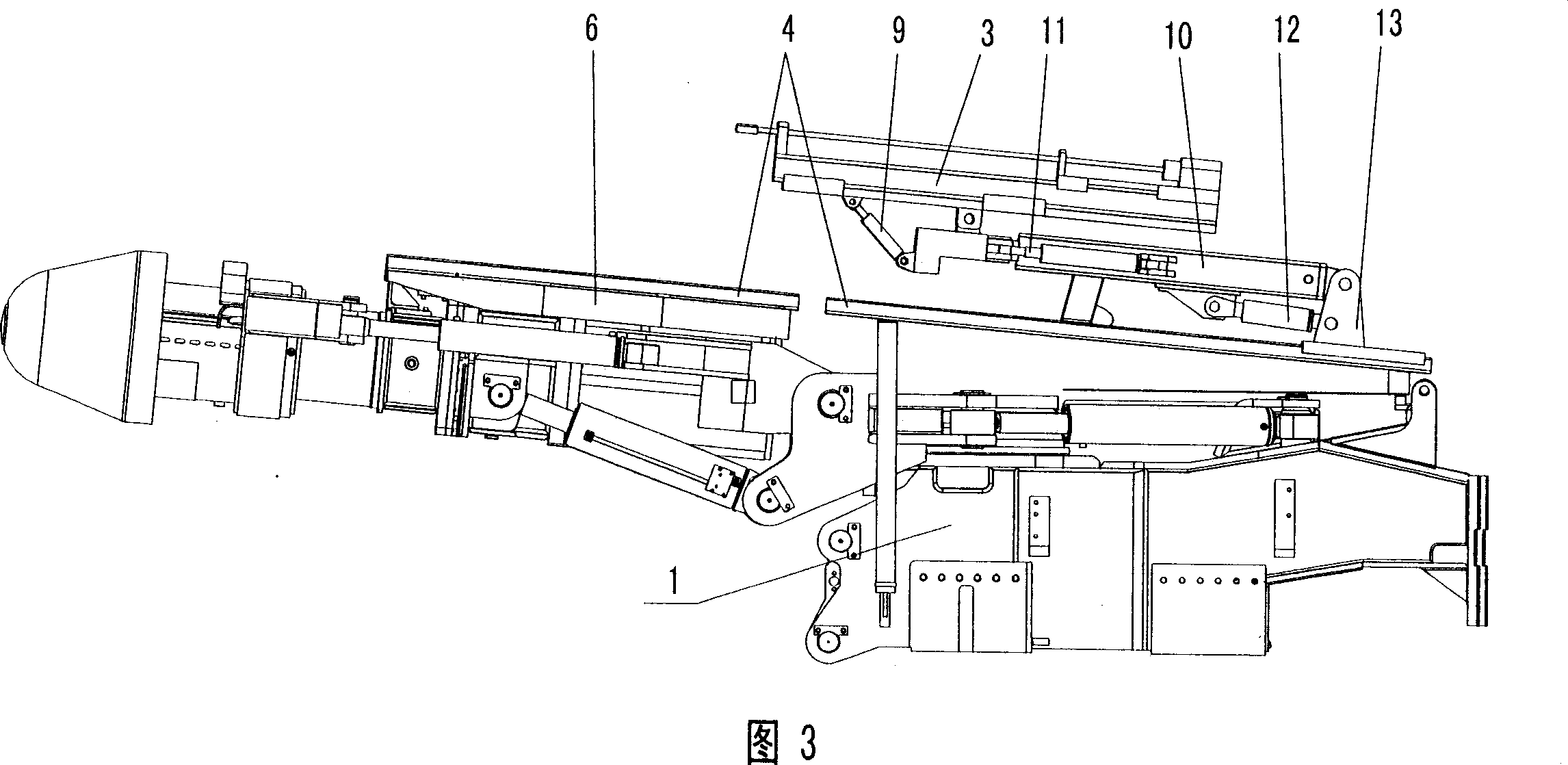

[0024] As shown in Figure 2 and Figure 3, the drilling machine 3 can be retracted and retreated to the rear of the roadheader 1 body. Its mechanism is mainly composed of four oil cylinders: angle adjustment oil cylinder 9, telescopic oil cylinder 10, swing oil cylinder 11, and support lifting oil cylinder 12. One end of the angle adjustment oil cylinder 9 is hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com