Carbon cream, carbon negative electrode of battery, preparation method thereof and super lead-acid battery

A super lead-acid battery, negative electrode technology, applied in battery electrodes, lead-acid battery electrodes, circuits, etc., to achieve the effect of improving cycle life, good electrical conductivity, and inhibiting hydrogen evolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

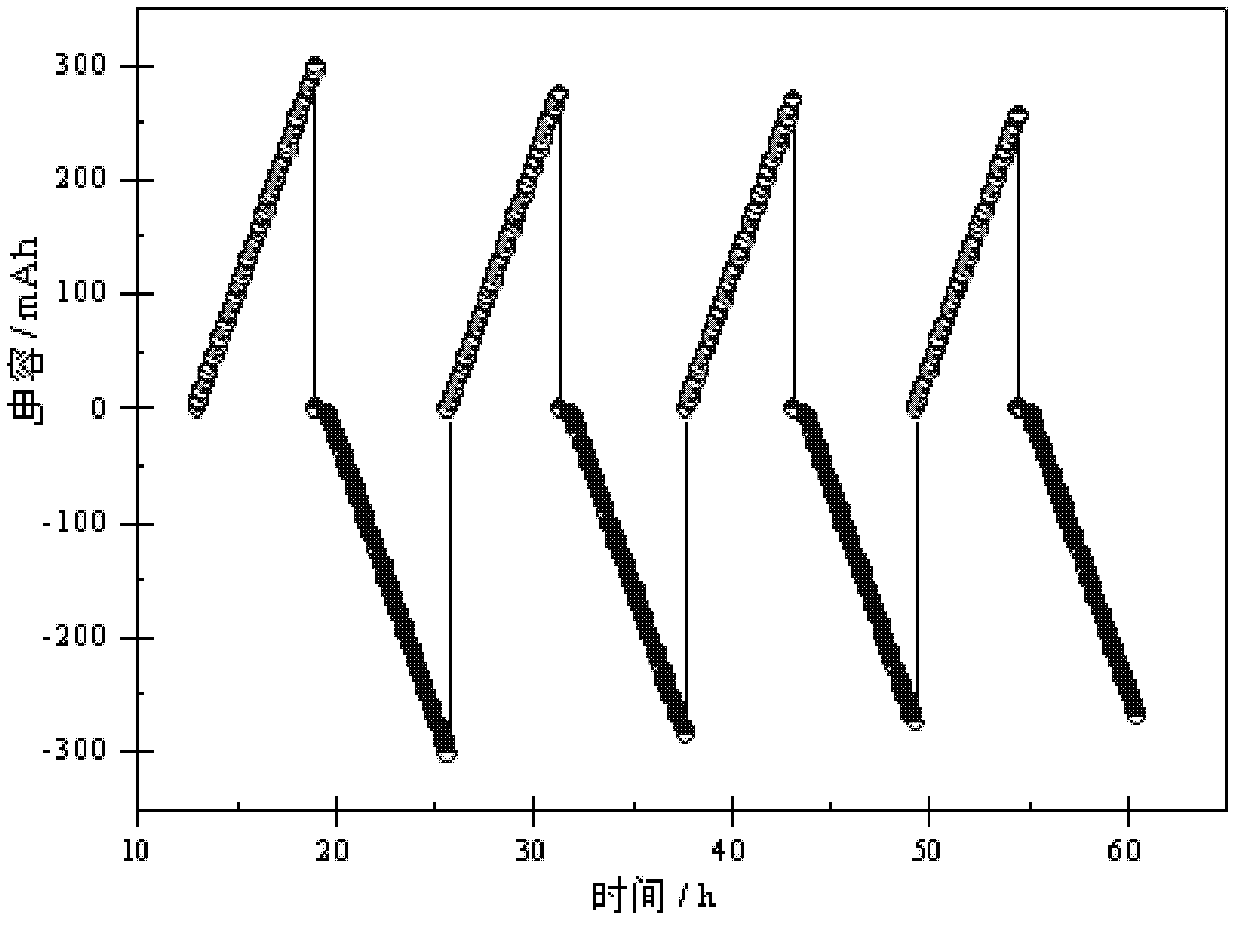

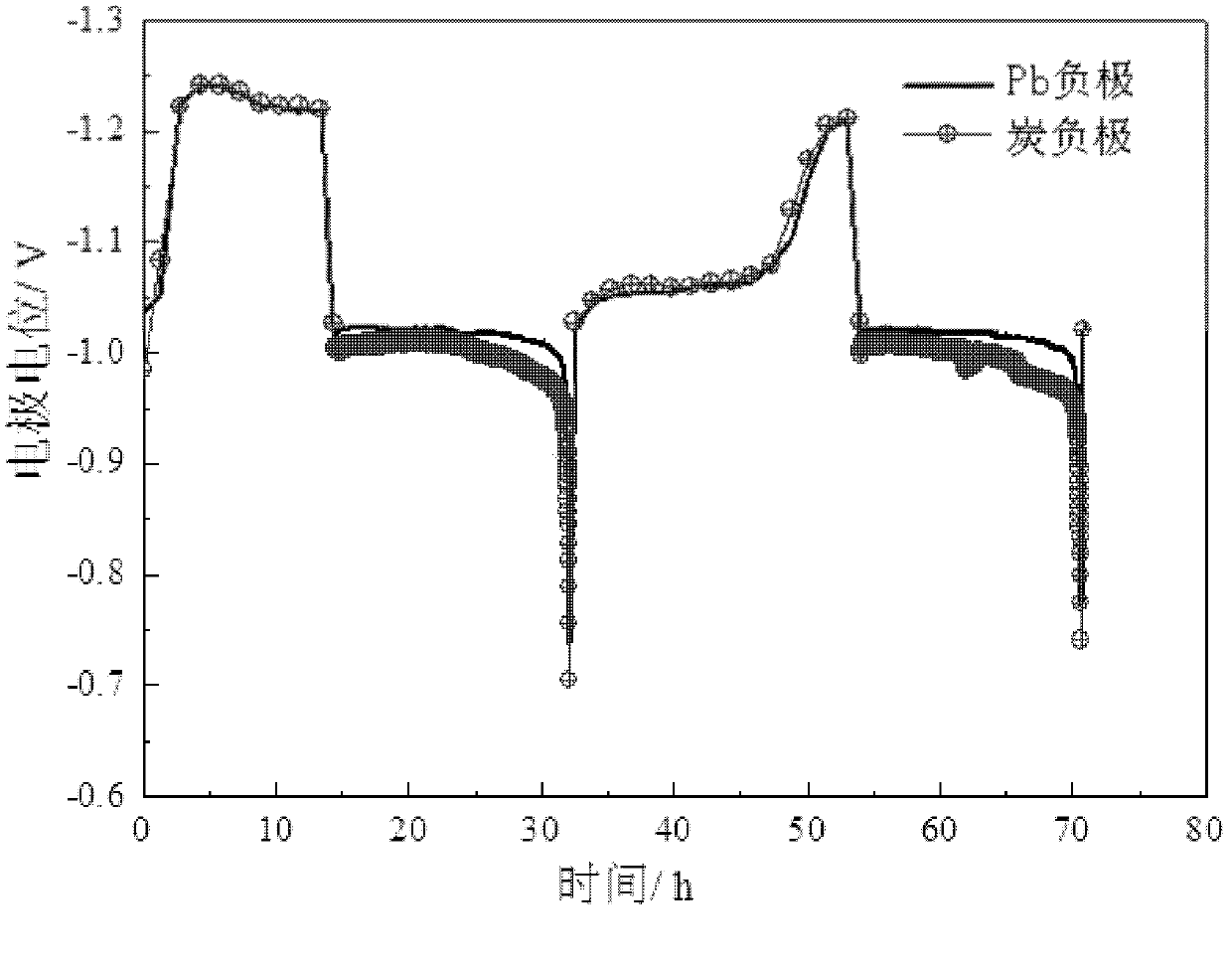

Image

Examples

Embodiment 1

[0044] This embodiment provides a carbon paste for a carbon negative electrode of a super lead-acid battery, which is formed by mixing a solid component and a liquid component, and the solid component contains:

[0045]A hydrogen evolution inhibitor with a content of 0.01% to 30%, whose general formula is M x N y o z , where M represents any one of Sr, Ba, Zn, and Cd, and N represents any one of Zr, Sn, and Pb, 0.5≤x≤1, 0.5≤y≤1, 2≤z≤3; among them, The content of hydrogen evolution inhibitor is the mass percentage relative to the total amount of solid components; that is to say, 0.01-30 mass parts of hydrogen evolution inhibitor is contained in 100 mass parts of solid components.

[0046] According to the above general formula, the hydrogen evolution inhibitor can be ZnPbO 3 , CdPbO 3 , BaPbO 3 , ZnSnO 3 , CdSnO 3 , CdZr 0.5 o 2 , SrPb 0.5 o 2 、Ba 0.5 Pb 0.5 o 2 、Cd 0.5 PbO 2.5 and other substances; preferably, N represents Pb, x=1, z=3, that is, the hydrogen ev...

Embodiment 2

[0059] The present embodiment provides a kind of preparation method of carbon paste for super lead-acid battery carbon negative electrode, it comprises the following steps:

[0060] 1) Weigh the specific surface area as 1800m 2 / g of activated carbon 800g, the specific surface area is 800m 2 15g of conductive carbon black per gram, 5g of nylon fibers with a length of 3mm, 100g of lead powder with a degree of oxidation of 75%, BaPbO as a hydrogen evolution inhibitor 3 80g, they were added in the agate mortar, dry mixed and dispersed for 5min to obtain the first mixture;

[0061] 2) Add 920g deionized water to the first mixture, grind for 10min to obtain the second mixture;

[0062] 3) Add 300 mg of sulfuric acid solution with a density of 1.4 g / ml (at 25° C.) to the second mixture, and continue grinding for 15 minutes to form the third mixture;

[0063] 4) 95 g of 10% polyvinylidene fluoride solution (as a binder) was evenly added dropwise into the third mixture, and ground ...

Embodiment 3

[0072] The present embodiment provides a kind of preparation method of carbon paste for super lead-acid battery carbon negative electrode, it comprises the following steps:

[0073] 1) Weigh the specific surface area as 1800m 2 / g of activated carbon 750g, the specific surface area is 800m 2 60g of conductive carbon black per gram, 5g of long 3mm nylon fiber, 125g of lead powder with 80% degree of oxidation, ZnPbO as hydrogen evolution inhibitor 3 60g, they were added in a stirring vessel, dry-mixed and dispersed for 5min to obtain the first mixture;

[0074] 2) Add 1000g of deionized water to the first mixture, stir for 10min to obtain the second mixture;

[0075] 3) Add 1800 mg of sulfuric acid solution with a density of 1.1 g / ml (at 25° C.) to the second mixture, and continue stirring for 15 minutes to form the third mixture;

[0076] 4) 100 g of a 10% polytetrafluoroethylene solution (as a binder) was evenly added dropwise into the third mixture, and stirred for 15 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com