Balancing pilot run transmission

A technology of transmission and trial operation, applied in transmission, gear transmission, static/dynamic balance testing, etc., can solve the problems of hurting people, damaging the structure or parts of machine 91, wasting time, etc., achieving easy maintenance, Environmentally friendly and maintenance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to have a more complete and clear disclosure of the technical content used in the present invention and the effects achieved, it is described in detail below, and please also refer to the disclosed drawings and figure numbers:

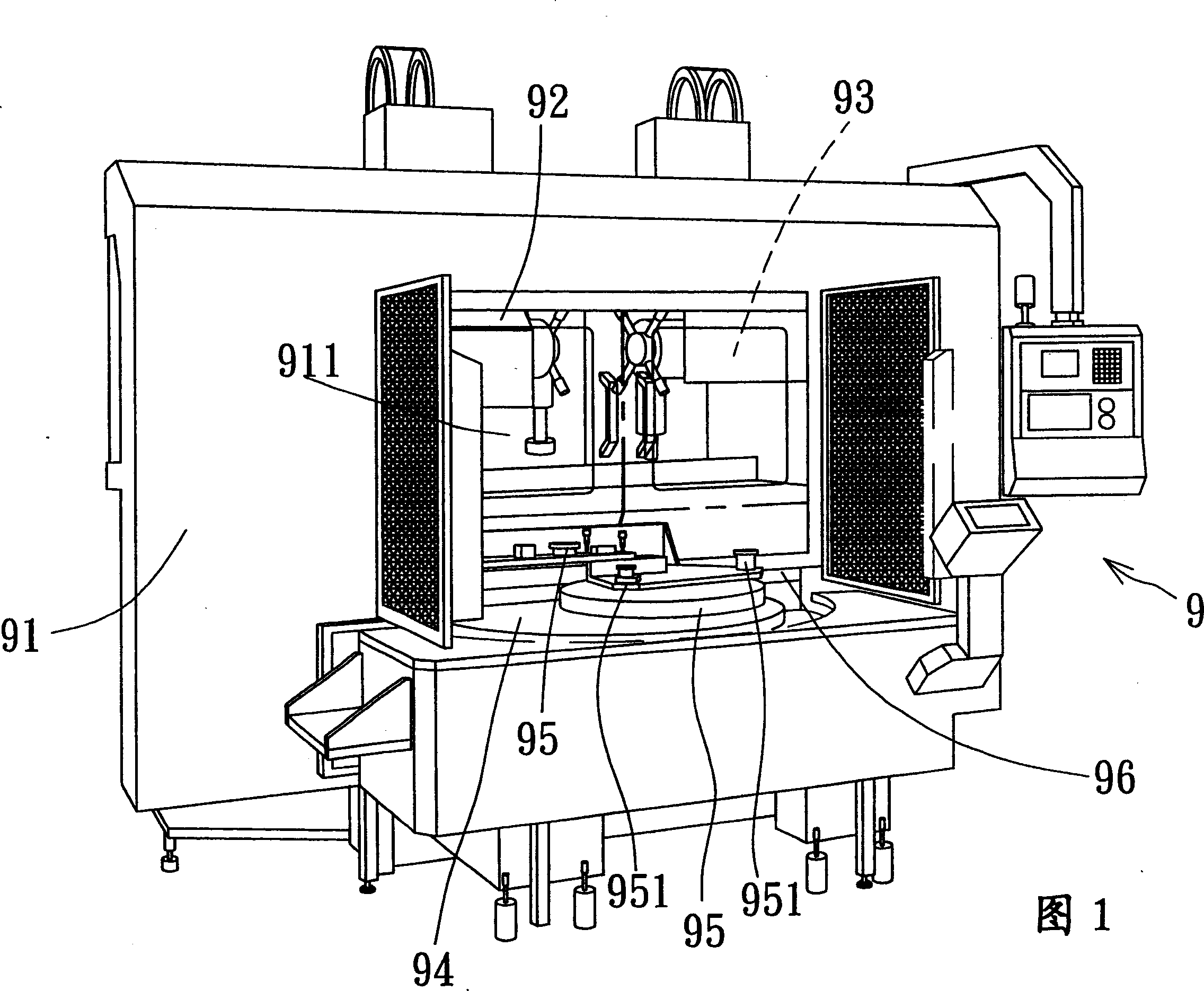

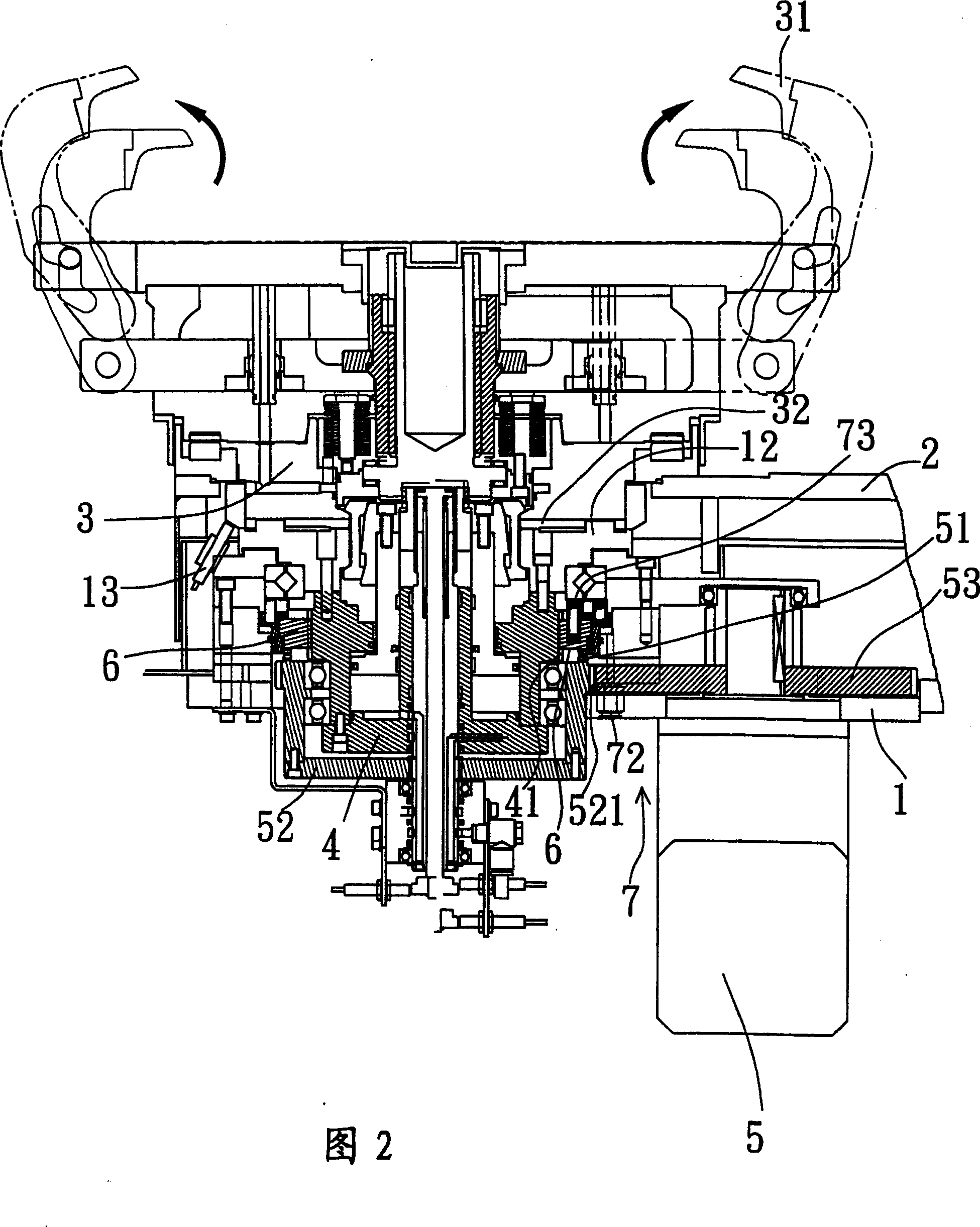

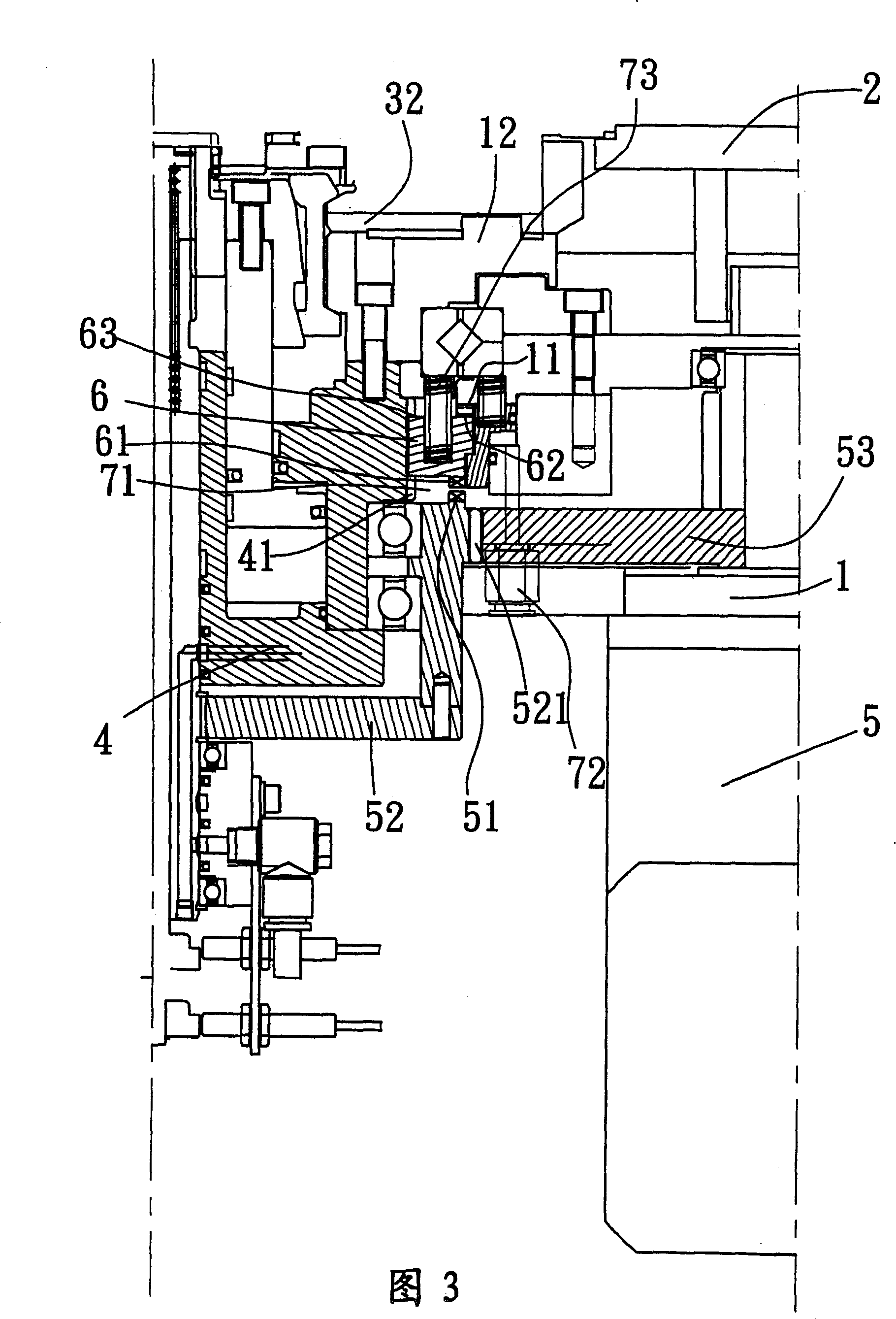

[0045] As shown in Fig. 2 to Fig. 5, it is an embodiment of the transmission device for balanced trial operation of the present invention, which includes a machine platform 1, a turntable 2, and two workbenches 3 (only one of the two workbenches is shown in this embodiment) 1), an inner rotating base 4, a power source 5, a clutch 6 and a driving group 7, wherein the machine 1 is used as the basis for parts assembly, and can be in the form of various vertical lathes, not in this embodiment As a limit, the turntable 2 is rotatably arranged on the machine table 1, and each workbench 3 is symmetrically and rotatably arranged on the turntable 2, and each workbench 3 is provided with a gripper 31, and the gripper 31 can be used for the workpie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com