Tyre digital gas-filling meter

A technology for inflatable meters and tires, used in container filling methods, gas/liquid distribution and storage, vehicle maintenance, etc., can solve problems such as low sensitivity to air pressure changes, increase costs, and inaccurate readings, achieve firm and reliable connections, and improve production. Efficiency, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

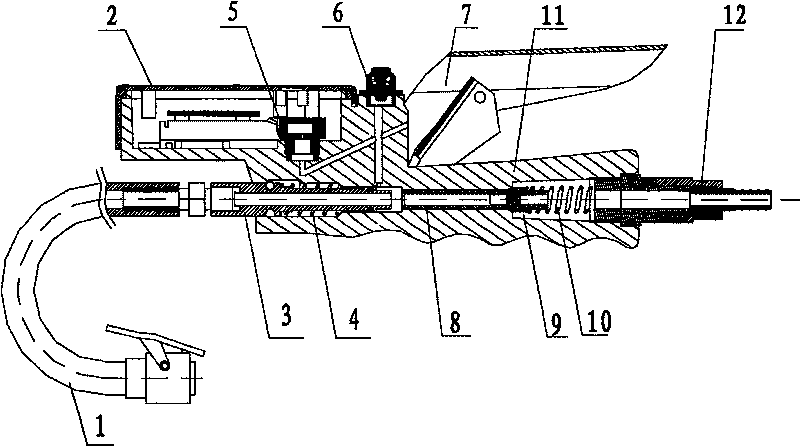

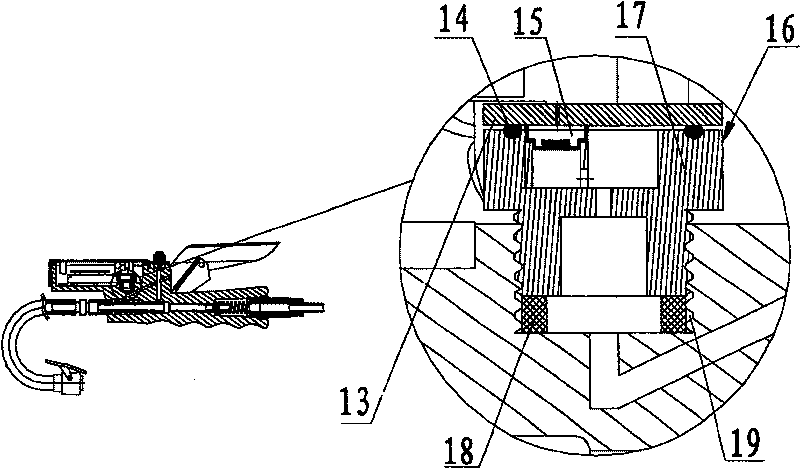

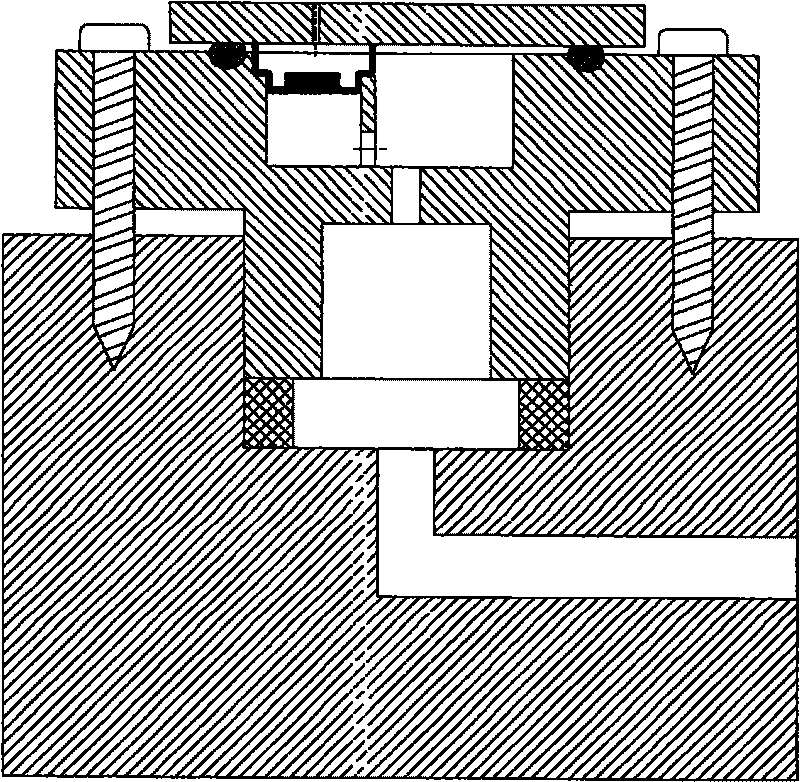

[0028] The present invention will be further described below in conjunction with accompanying drawing.

[0029] Such as Figure 1 to Figure 4 As shown, the digital display inflatable meter of this embodiment, when the air inlet joint part is connected to the air source, press the handle 7 at this time, the handle 7 will drive the pumping part 3 to move to the right, when the pumping part 3 moves a certain distance Finally, it will touch the airtight tube 8. If the handle 7 continues to be pressed at this time, the pumping part 3 will lift the airtight tube 8. At this time, the air source is connected with the tire, and the compressed air in the air source just enters the tire. Tire Air Refill. When the handle is released, the inflating part 3 will move to the left under the action of the elastic force of the spring one 4. At this time, the airtight tube 8 will also move to the left under the effect of the spring two 10. When the airtight tube 8 has moved a certain distance, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com