Guiding device for waste gas turbocharger of piston-type internal combustion engine with heavy oil as fuel

A technology of exhaust gas turbine and guide, applied in the field of guide, can solve the problems of accidental displacement of adjustment ring and guide, achieve the effect of reducing accidental displacement, realizing structural type, and reducing installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

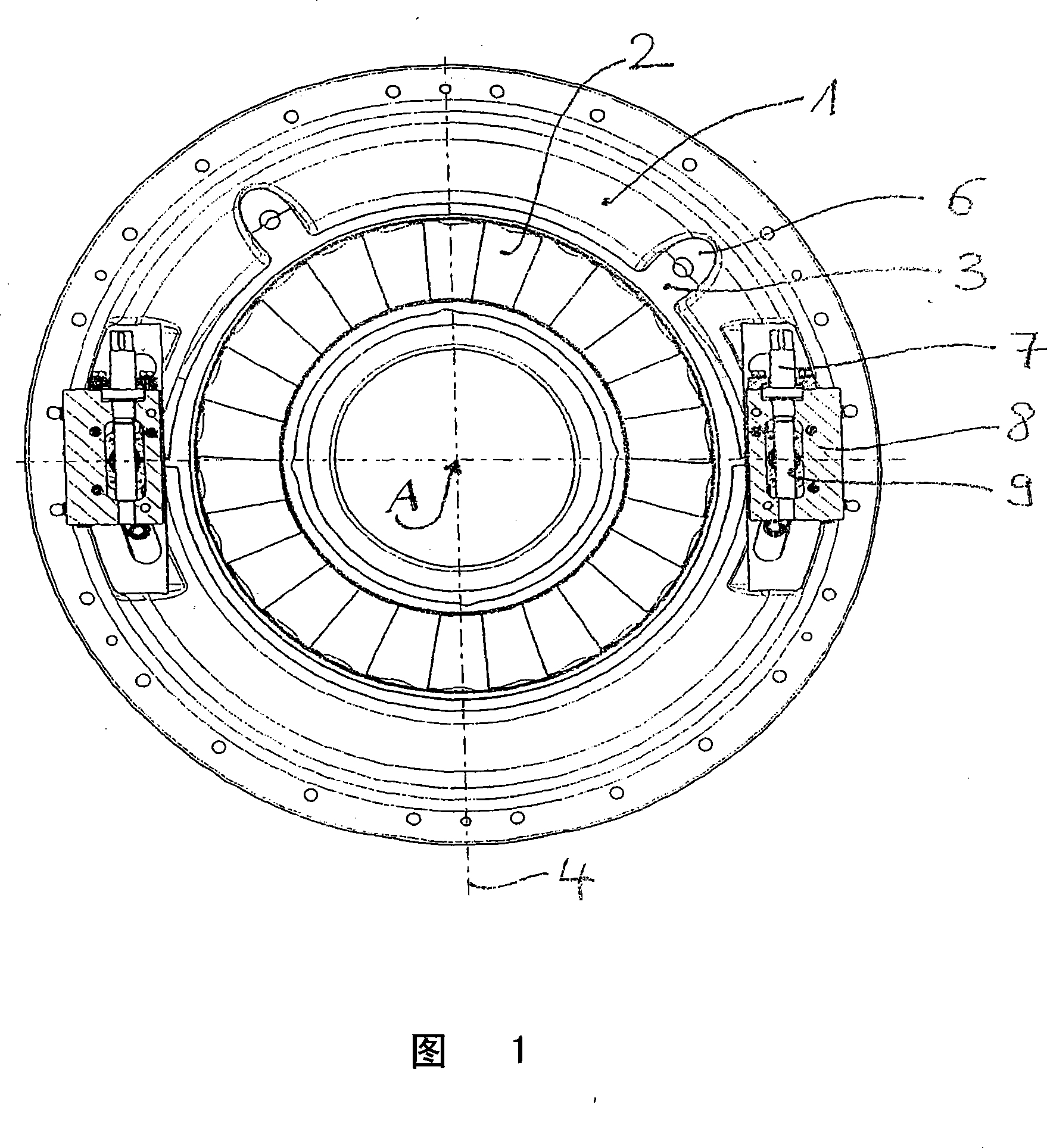

[0030]Figure 1 shows a guide designed according to a design of the present invention. The guide comprises an adjusting ring 6 , which is mounted rotatably about the turbine axis A in the turbine housing 1 . By turning the adjustment ring 6 around the turbine axis A, the guide vanes 2 supported in the guide vane holder 3 can pivot, thereby adjusting the exhaust gas flow to match the exhaust gas turbine (not shown in the figure) . The guide vane 2 is connected to the adjusting ring 6 through an adjusting rod in a manner not shown in detail in the figure.

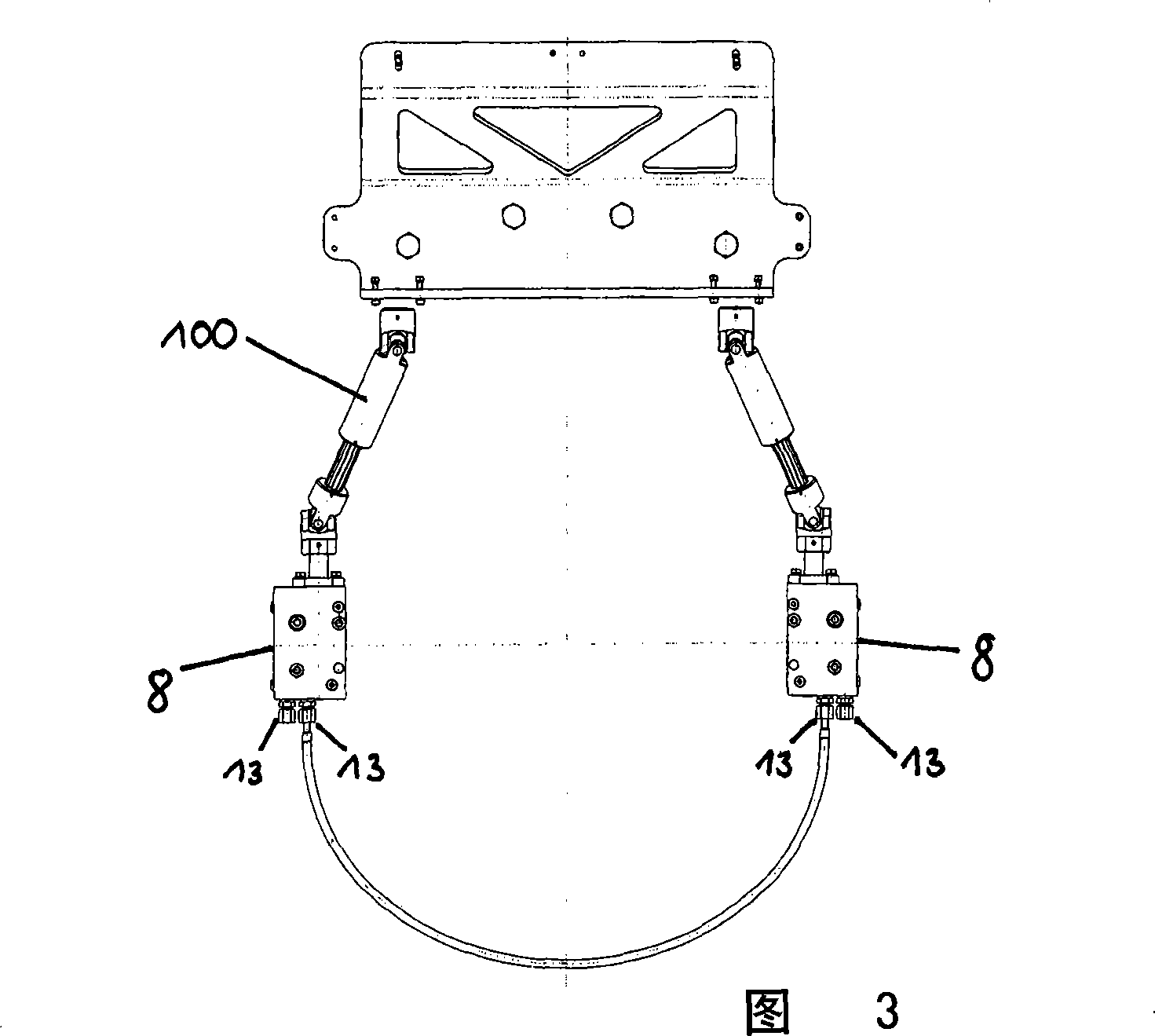

[0031] In order to rotate the adjusting ring 6 around the turbine axis A, two adjusting devices are provided symmetrically distributed on the circumference of the adjusting ring 6 . Each adjustment device includes a screw rod 7 that is connected to and driven by a universal joint shaft 100 (accompanying drawing 3 ) and an actuating motor (not shown in the figure) for anti-rotation.

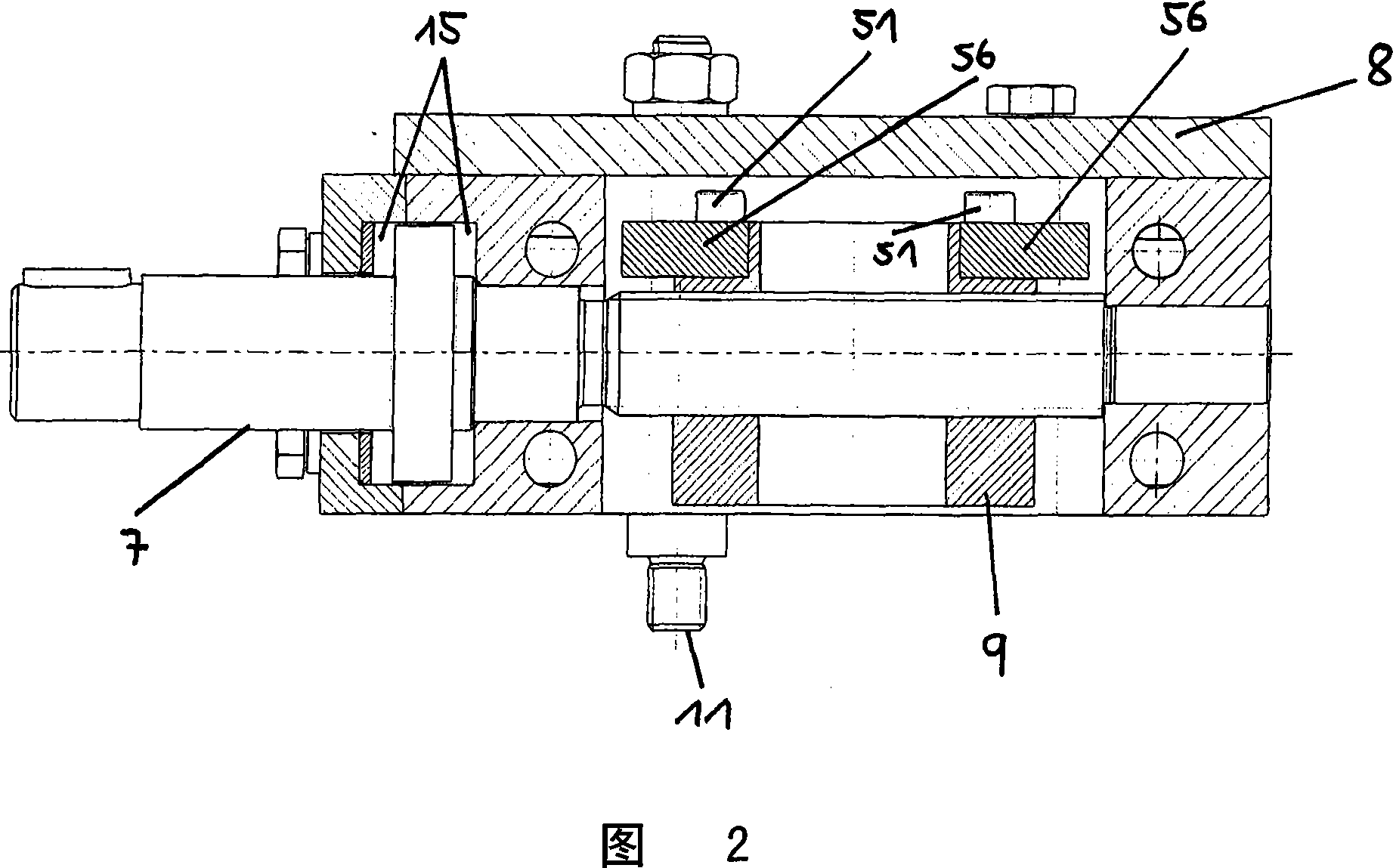

[0032] The screw 7 is mounted rotatably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com