Thermodynamic expansion valve

A thermal expansion valve and valve body technology, applied in the field of expansion valves, can solve the problems that the temperature sensing bulb cannot be controlled correctly, and it is difficult to realize product miniaturization, etc., and achieve the effect of simple and reliable sealing, simple sealing operation, and increased degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

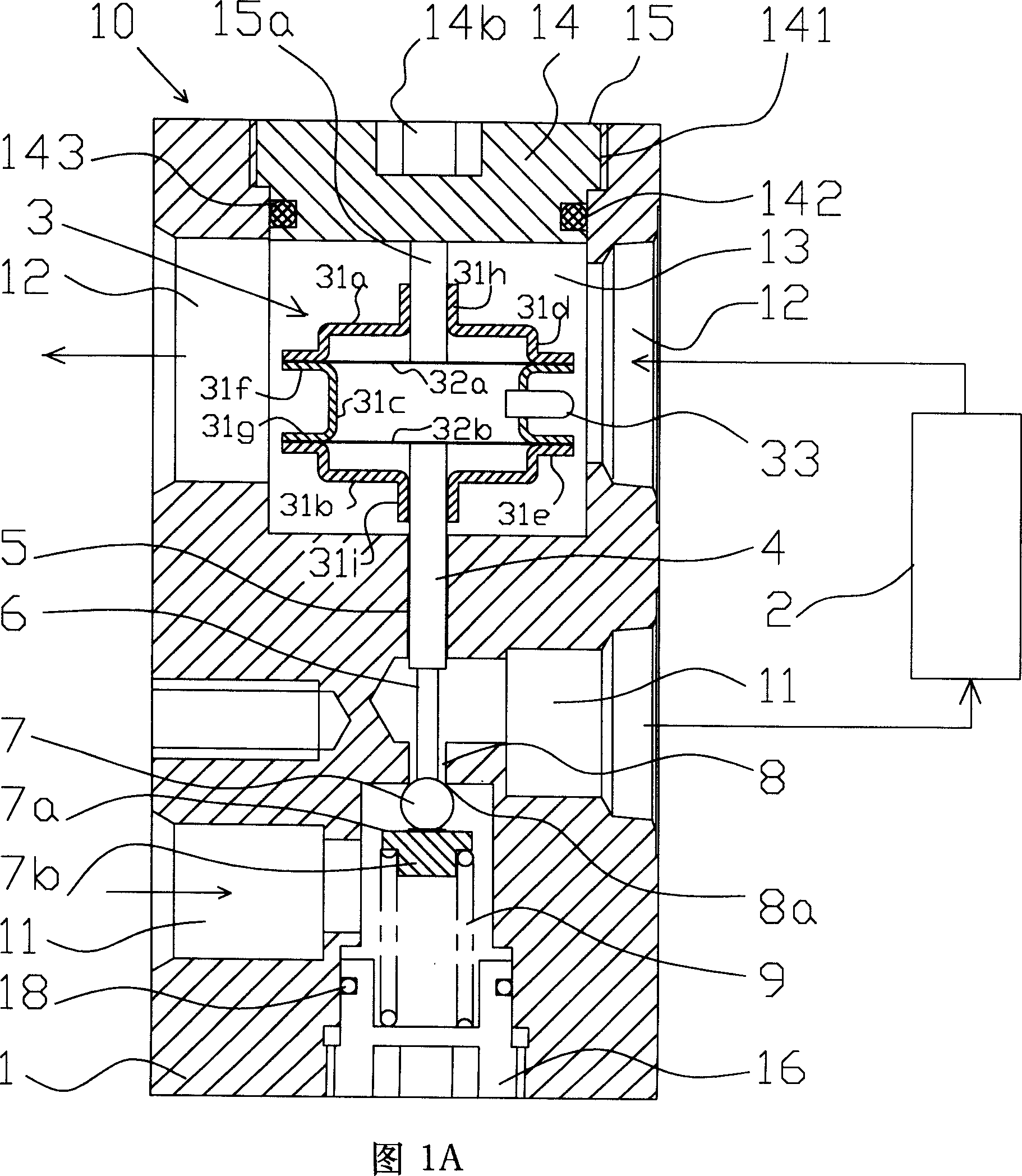

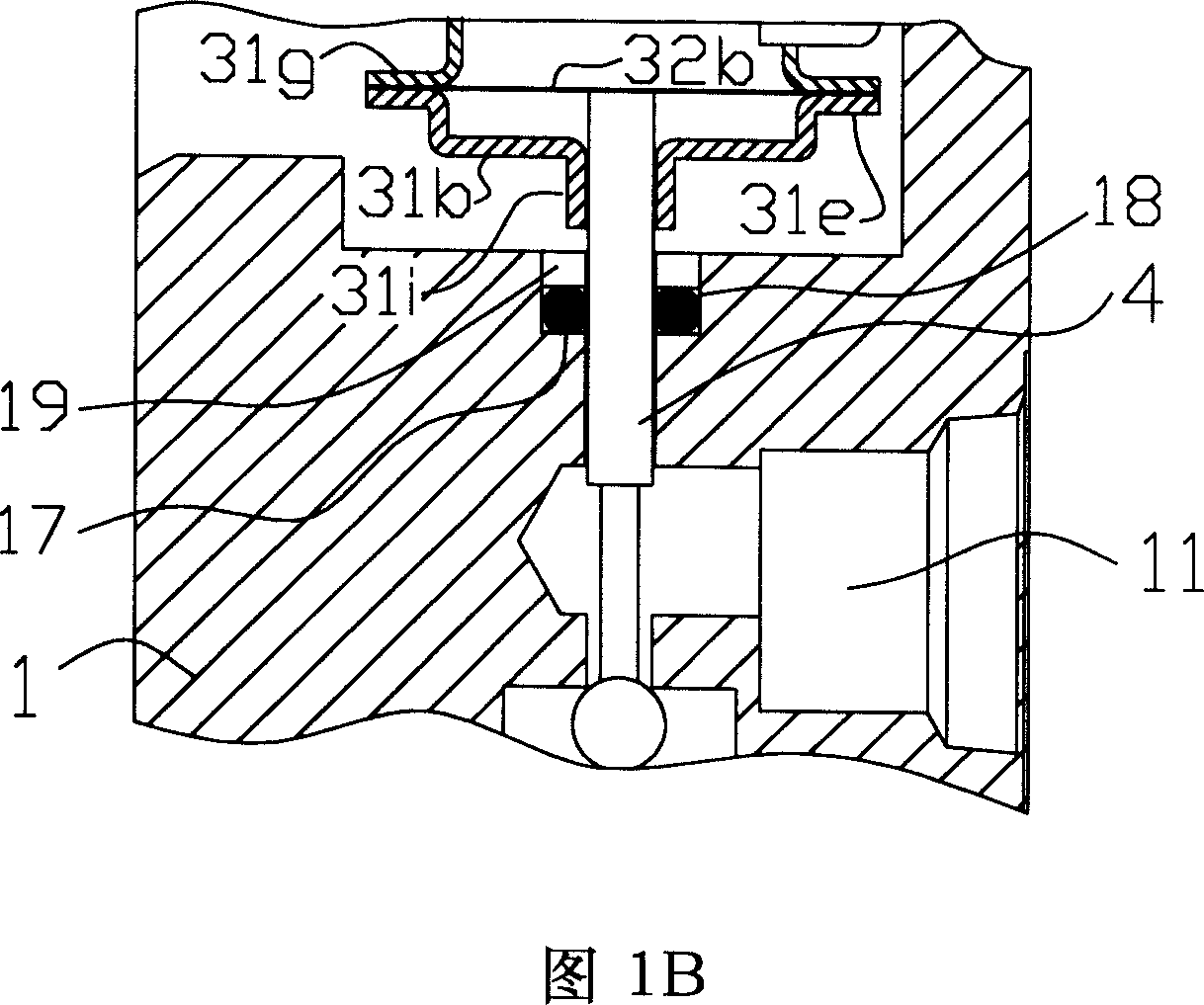

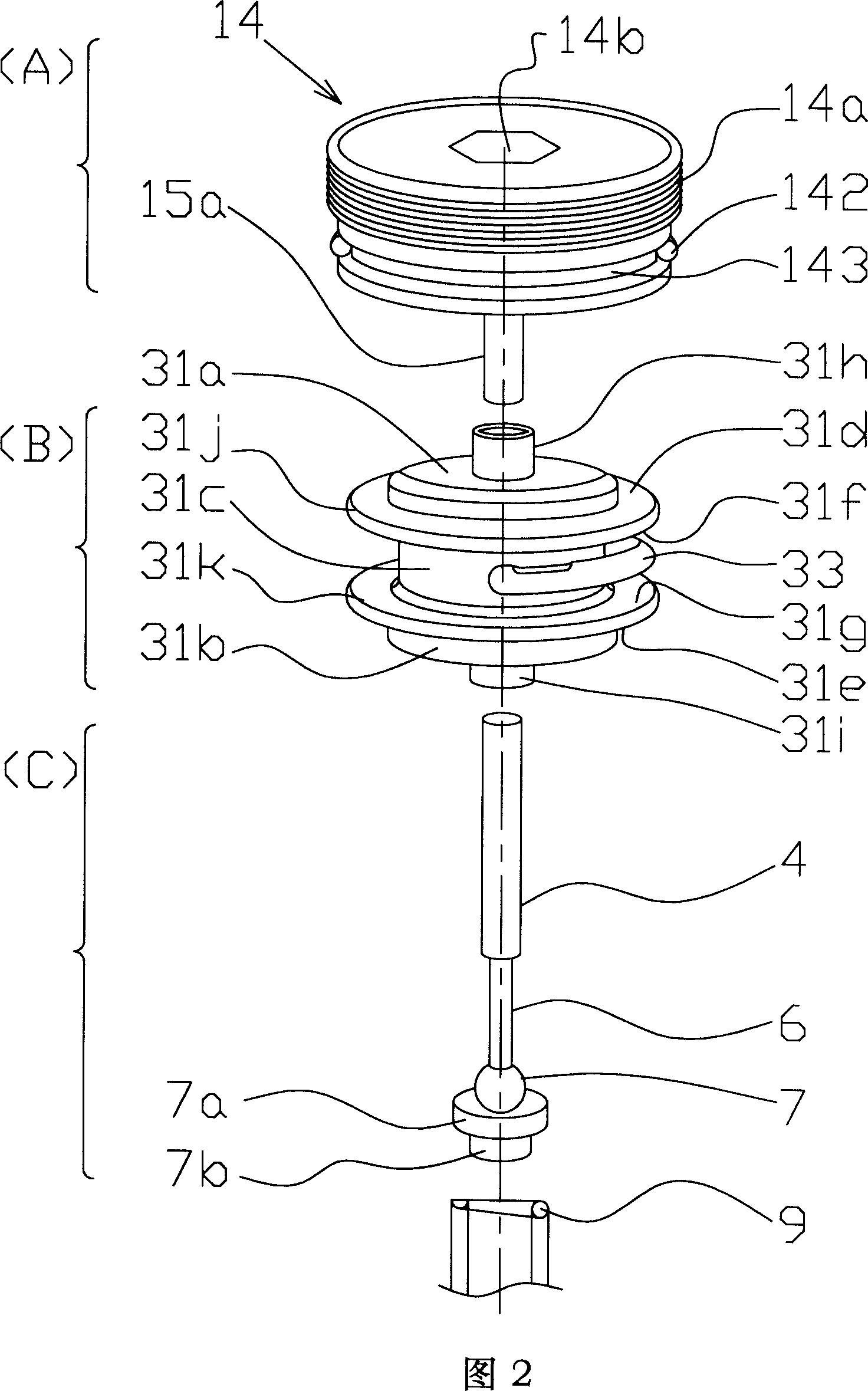

[0040] FIG. 1A is a longitudinal sectional view of a thermal expansion valve 10 according to an embodiment of the present invention. This thermal expansion valve is used in a refrigerating cycle of an automobile air conditioner and the like like conventional expansion valves.

[0041] In the figure, a prismatic valve body 1 made of metal such as aluminum is formed, and the high-pressure refrigerant discharged from the compressor (not shown) flows into the high-pressure passage 11 of the evaporator 2 and the low-pressure refrigerant discharged from the outlet of the evaporator 2 flows into the evaporator. The low-pressure passage 12 of the compressor, the high-pressure passage 11 and the low-pressure passage 12 are parallel to each other. On the way from the outlet of the evaporator 2 into the low-pressure passage 12 of the compressor, an insertion portion 13 for inserting the temperature-sensing package 3 is provided, and an insertion hole 15 larger than the temperature-sensing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com