Method for manufacturing transistor structure

一种晶体管、半导体的技术,应用在晶体管、半导体/固态器件制造、半导体器件等方向,能够解决解决方案困扰技术人员、没有给出或暗示解决方案等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

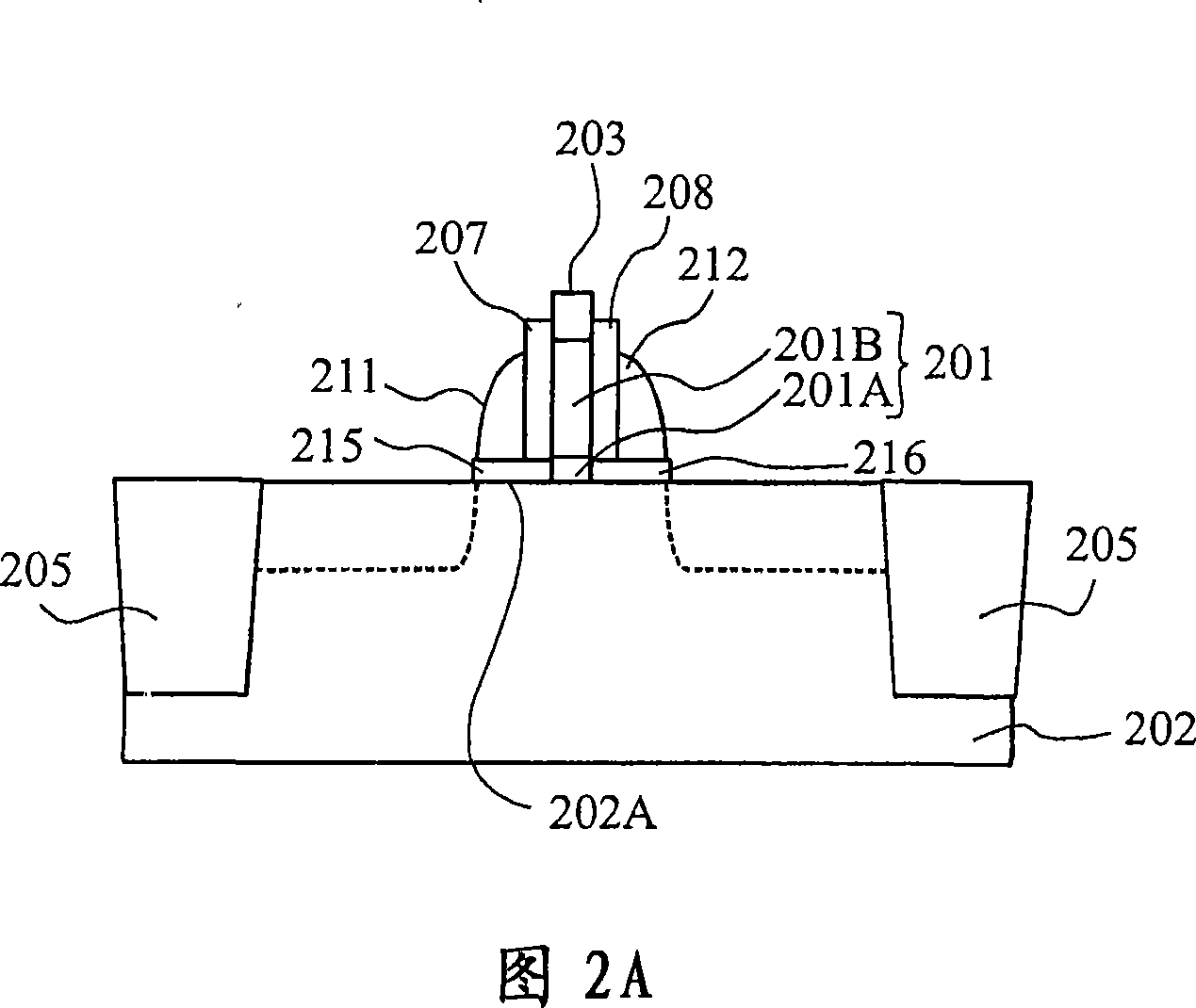

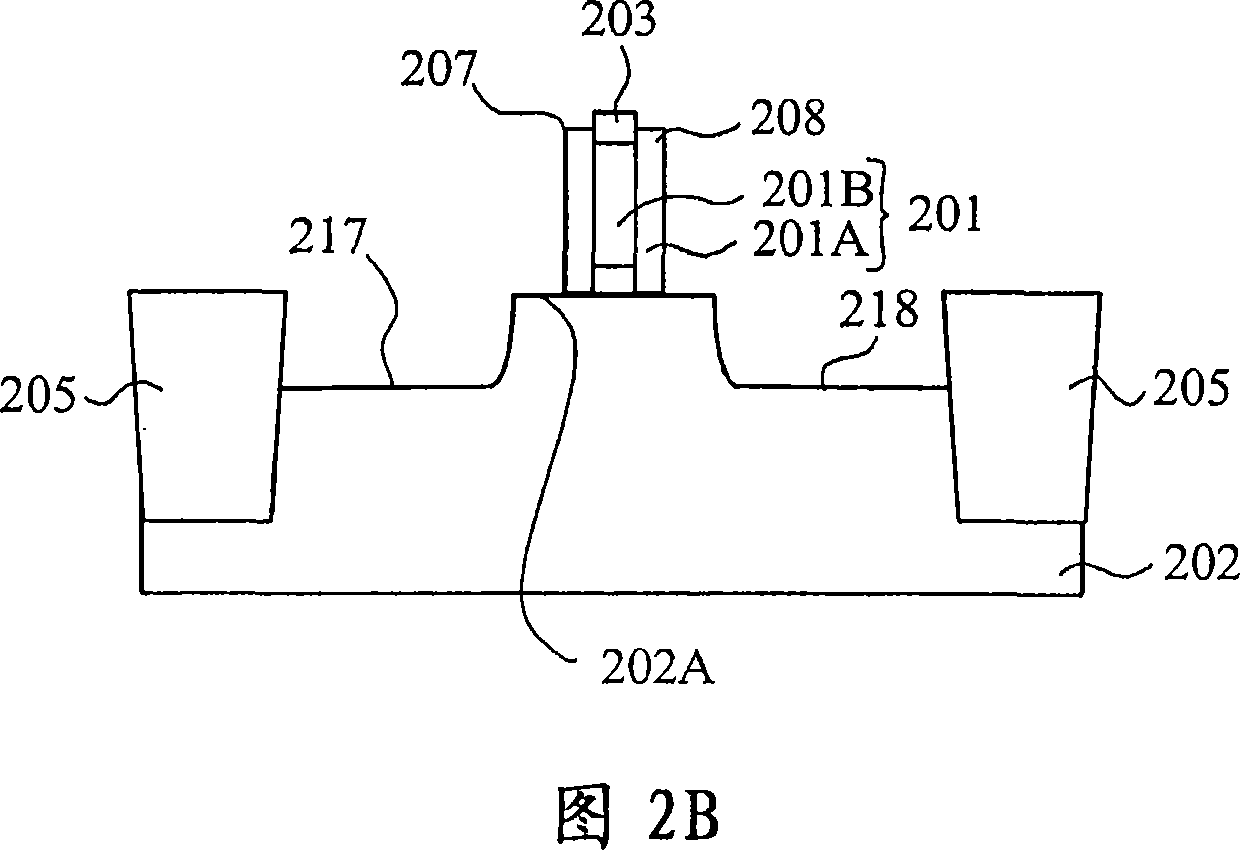

[0045] According to the first embodiment of the invention, the disposable oxide spacer elements 215, 216 are consumed during the formation of the first portion 217, 218 of the deep stress body recess. Advantageously, fabrication process parameters such as the thickness of the disposable oxide spacer elements 215, 216, etch conditions, and other parameters are adjusted such that approximately at the same time as the formation of the stressor recessed first portions 217, 218 is completed, the The exposed portions of the disposable oxide spacer elements 215, 216 are fully consumed. Advantageously, an etch with low selectivity between the substrate material and the disposable oxide isolation elements 215, 216 is used.

[0046] Advantageously, reactive ion etching of source and drain stressor recessing is performed using a gaseous etchant comprising a flowing gas mixture. The mixture of flowing gases may include: HBr, O2, He, Cl2, SF6, N2 (alone or in combination) at a flow rate f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com