Ink ribbon cassette and printer including ink ribbon

A technology of ink ribbon box and printer, which is applied in the direction of ink ribbon box, printing, inking device, etc. It can solve the problems of deviation of positioning accuracy of printer device and difficulty in assembling operation of tape box, and achieve the effect of improving positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

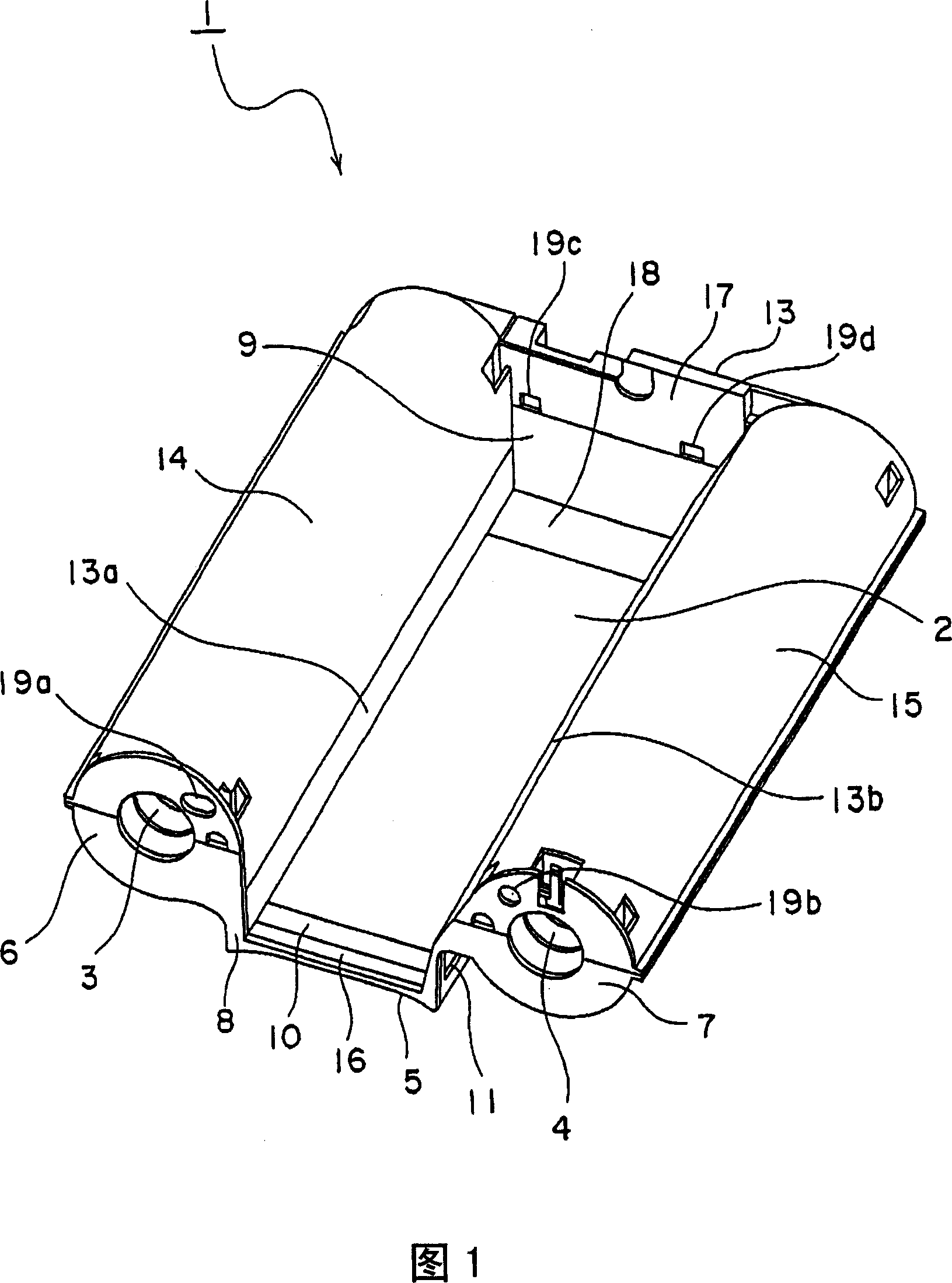

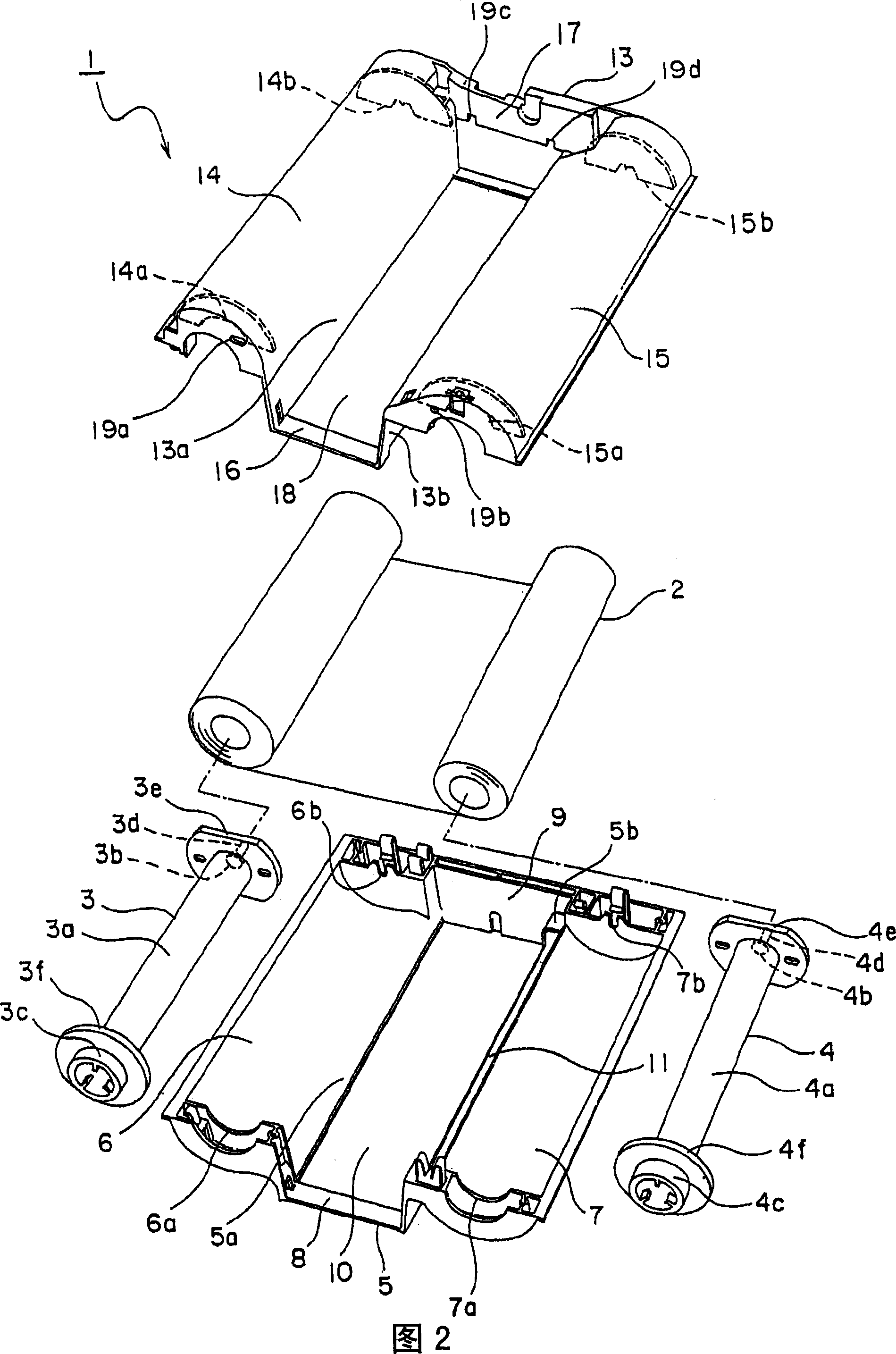

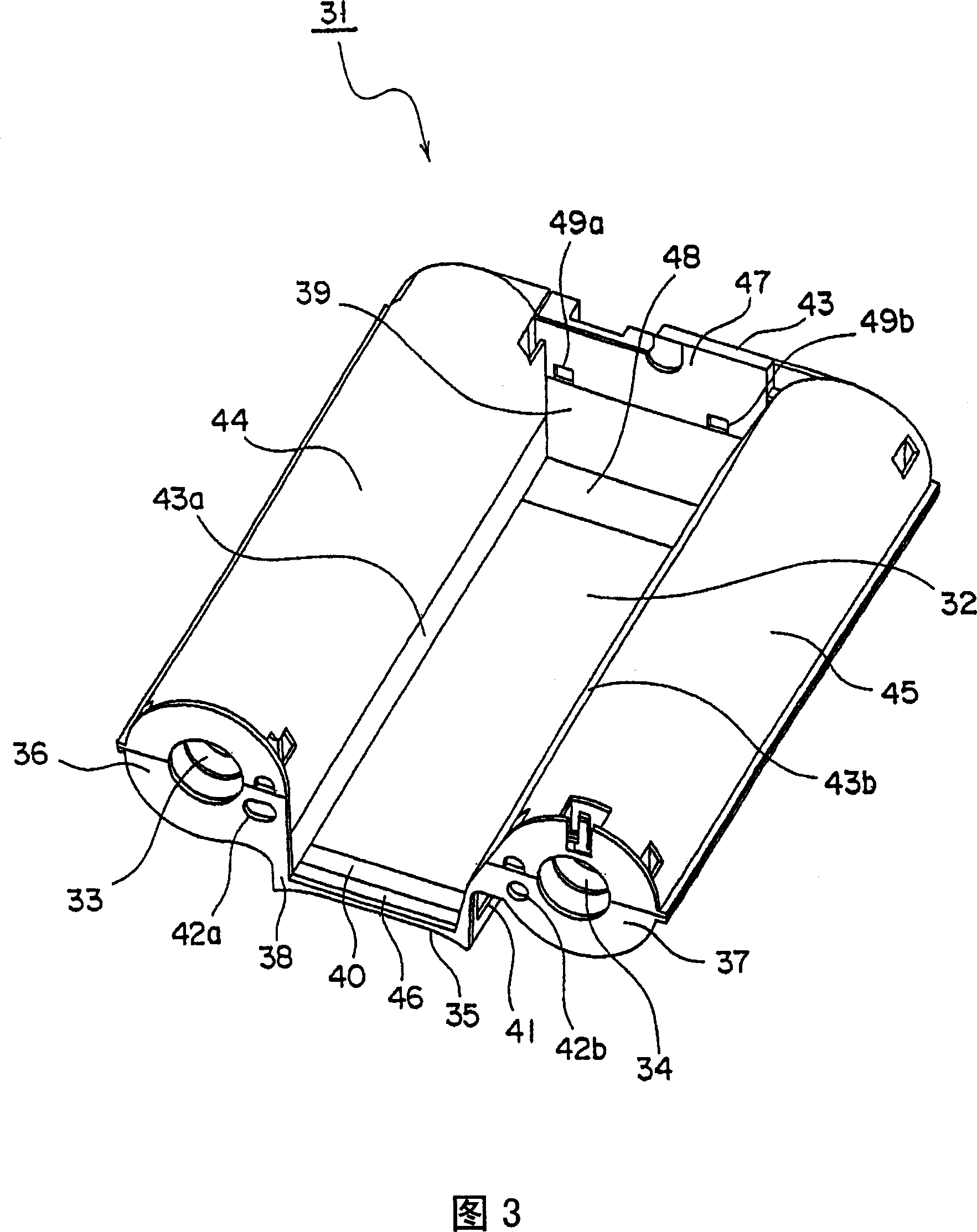

[0039] The ink ribbon cartridge and printer of the present invention will be described below based on the embodiments shown in the accompanying drawings.

[0040] 1 is a schematic perspective view showing an embodiment of an ink ribbon cartridge according to the present invention; FIG. 2 is an exploded perspective view of FIG. 1; FIG. Figure 7 is a cross-sectional view showing the thermal head of the printer (ink ribbon cassette attached) according to an embodiment of the present invention in a state of lowering the thermal head. Sectional view of the main part.

[0041] As shown in Figures 1 and 2, the ink ribbon cassette 1 of this embodiment is formed by fitting the first housing 5 and the second housing 13, and the first housing 5 and the second housing 13 are respectively rotatable. The supply core 3 and the take-up core 4 on which the long ink ribbon 2 is wound are supported in a stable manner.

[0042] As shown in FIG. 2 , the supply core 3 and the take-up core 4 are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com