Rope-winding method for light folding arm type tower crane lifting-folding arm mechanism

A technology of hoisting wire rope, arm type, applied in the field of hoisting and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

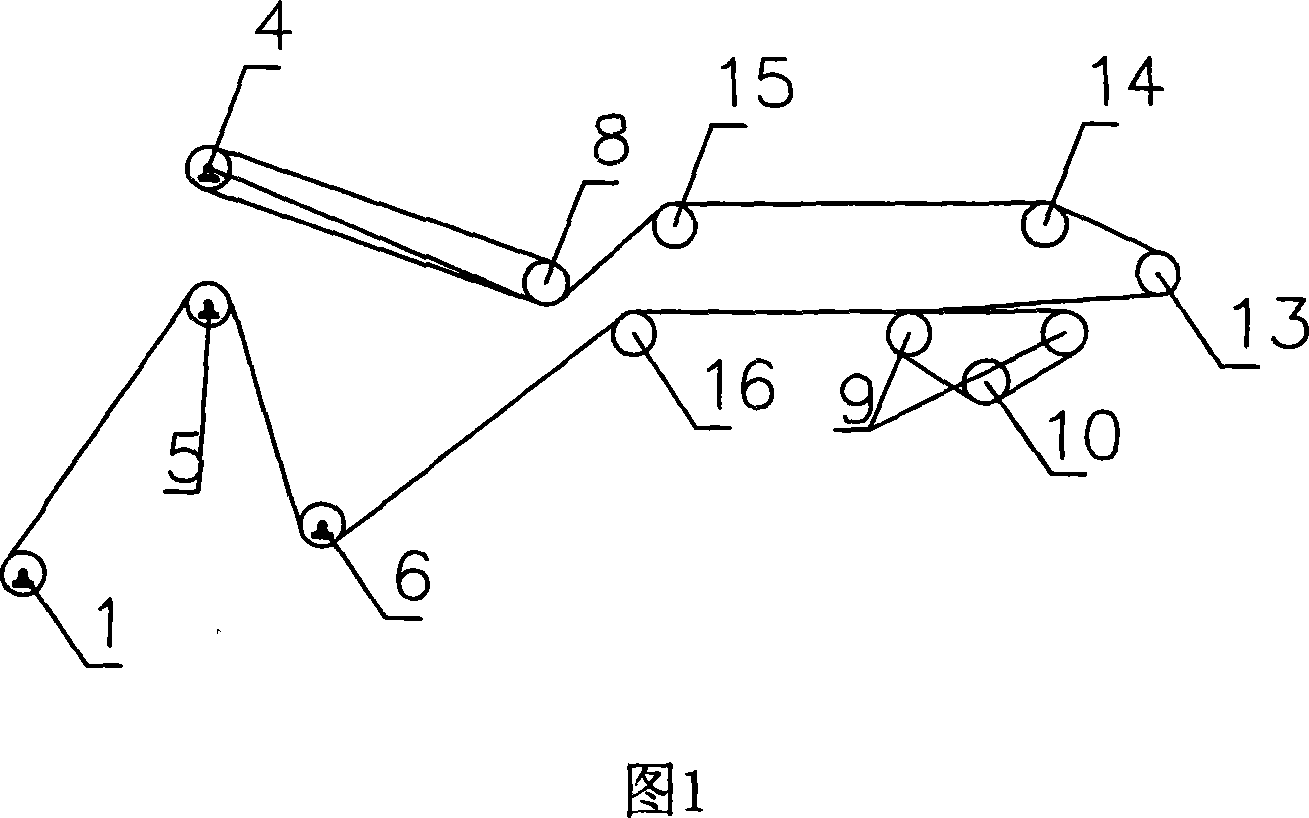

[0012] In Fig. 1, the wire rope of the lifting-folding arm mechanism goes around the winch 1, the guide pulley II5, the guide pulley III6, the angle pulley 16, the hoisting pulley 9 on the luffing trolley 9, the hook pulley 10, and the guide pulley in turn IV13, guide pulley V14, guide pulley VI15, folding arm pulley block 8, the end is fixed on the guide pulley I4.

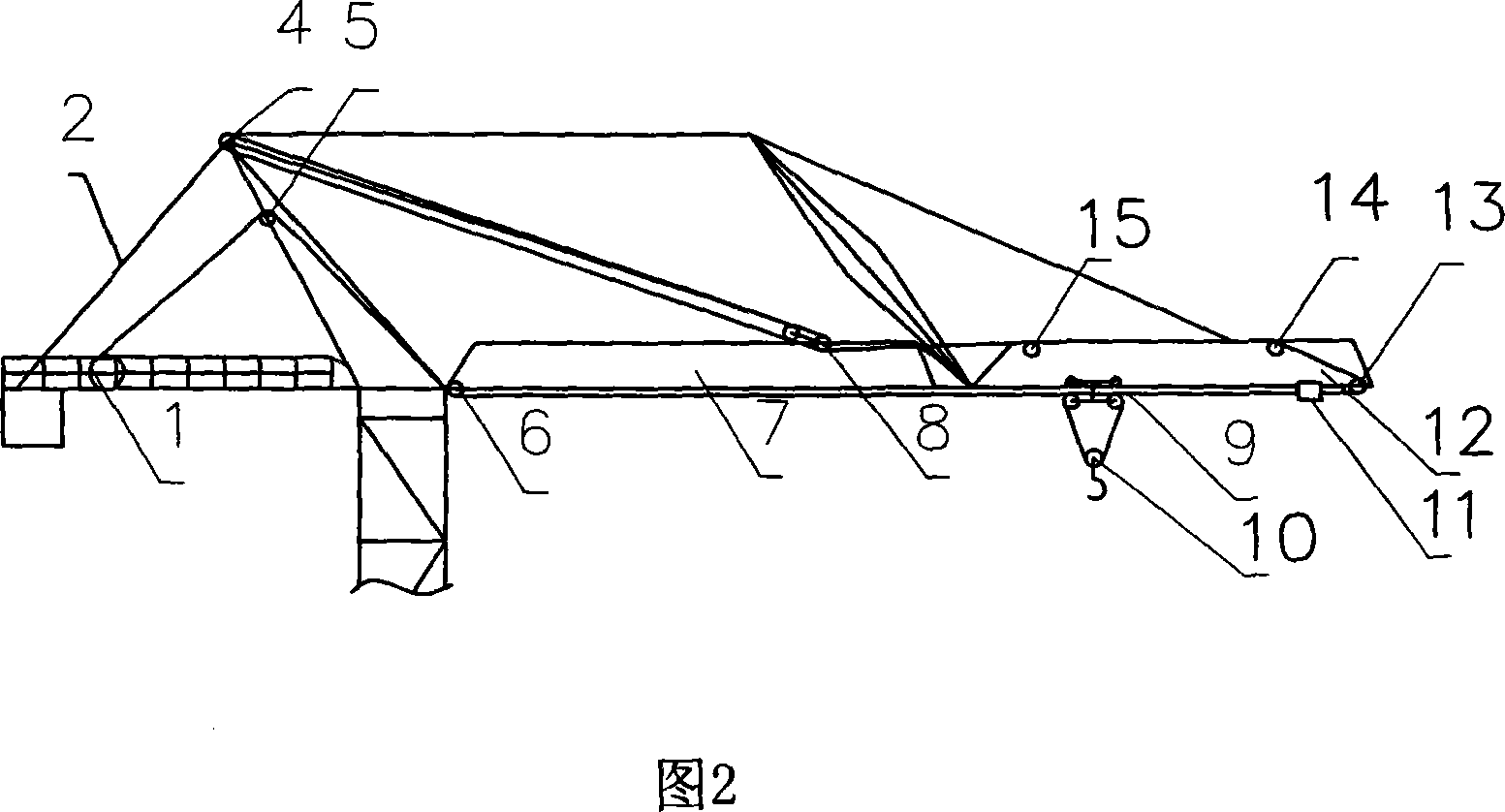

[0013] In the horizontal working state shown in Figure 2, the knuckle pulley 16 is sent to the root of the rear arm 7, and the wire rope at the end of the forearm 12 is fixed by the wire rope fixing device 11, so the tower crane is the same as the original light knuckle-arm tower crane when it is working. the same.

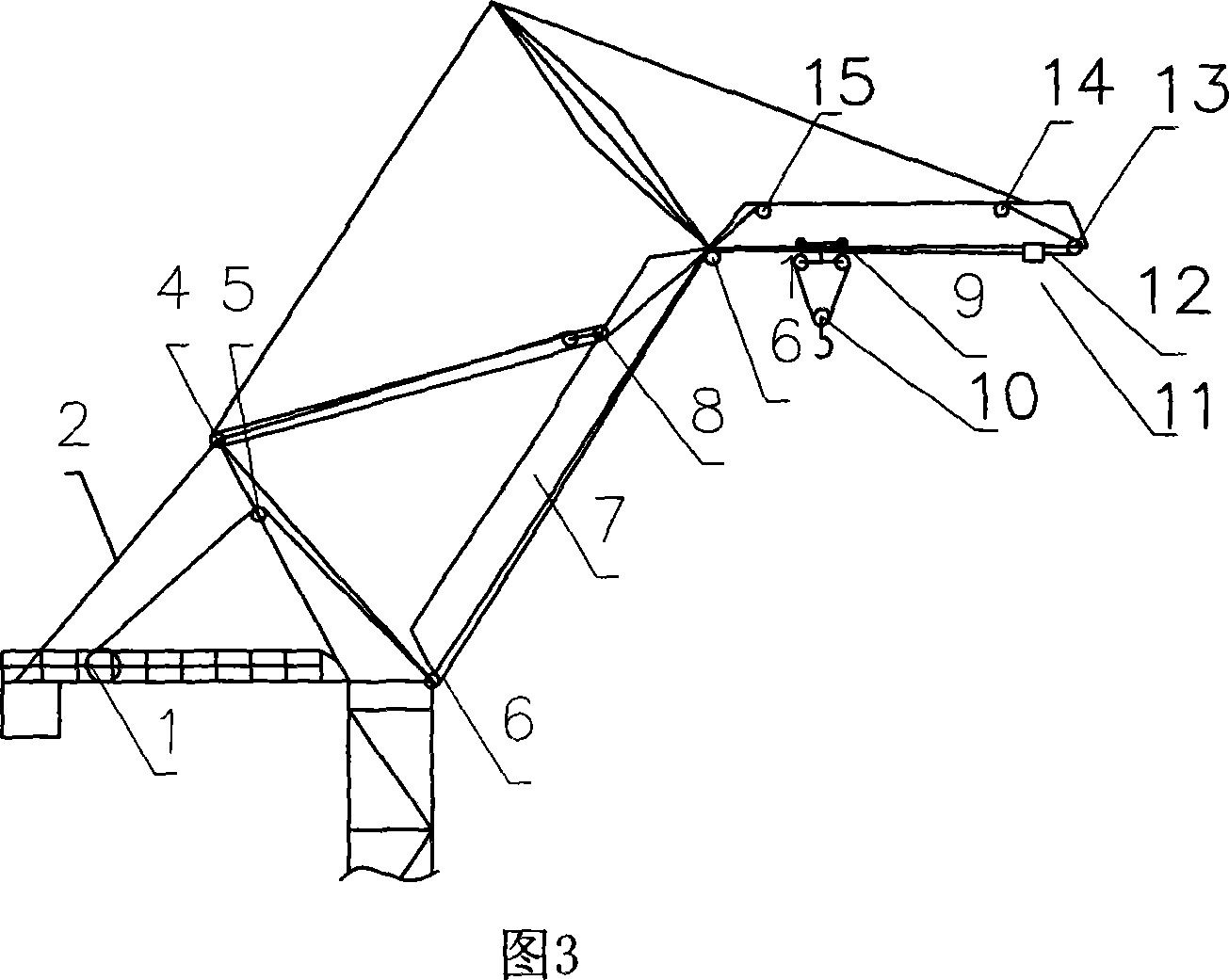

[0014] When performing folding arm conversion, send the angled pulley to the root of the forearm and install it, start the hoisting mechanism to make the hook 10 contact with the luffing trolley 9, unfix the wire rope at the end of the forearm, continue to start the hoisting mechanism, the rear arm 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com