Corn strew grinding return-to-field machinery

A technology of corn stalks and racks, which is applied in the field of corn stalk crushing and returning machines, which can solve the problems of uneven scatter and affect the growth and development of wheat, and achieve the effect of even scatter scatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

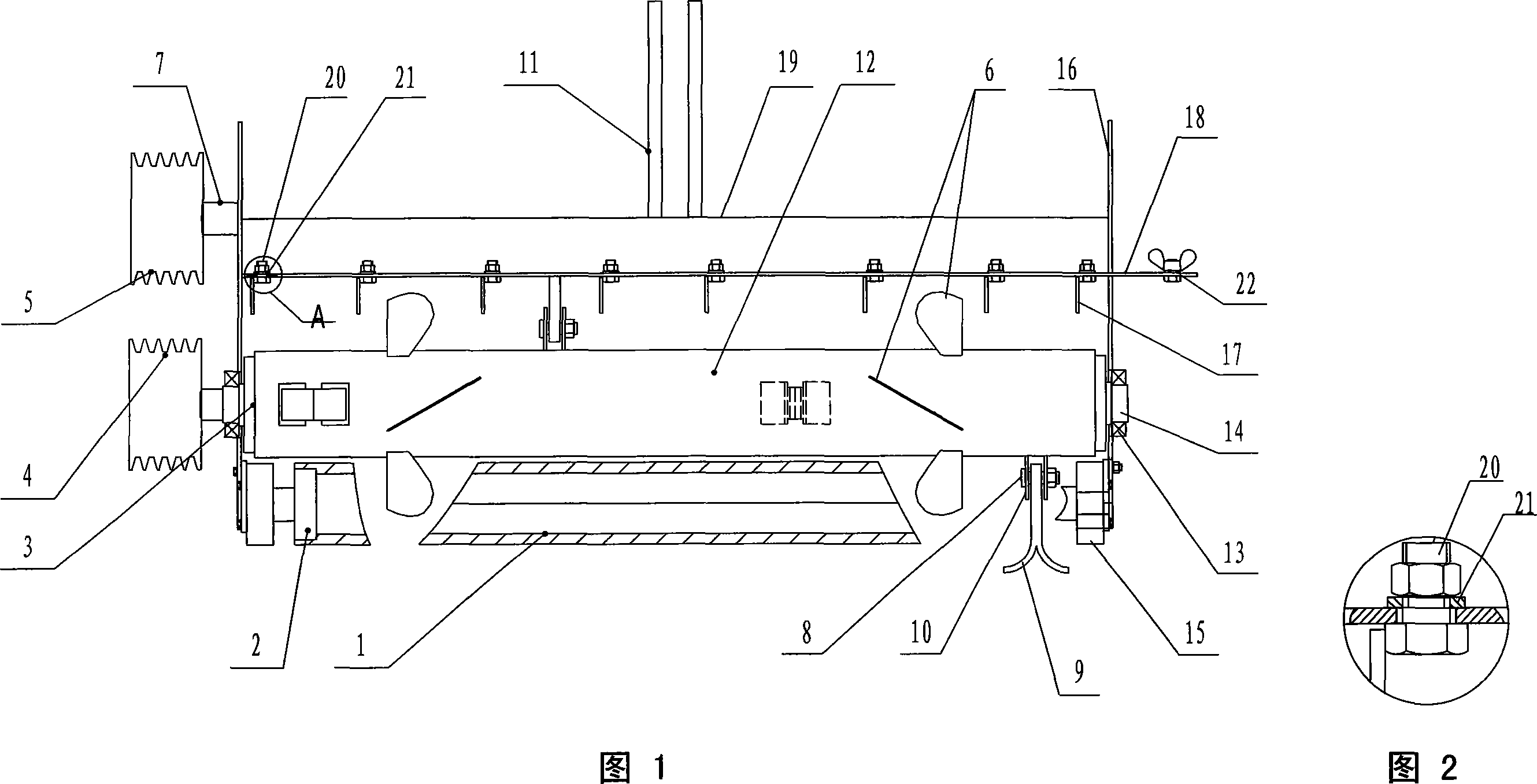

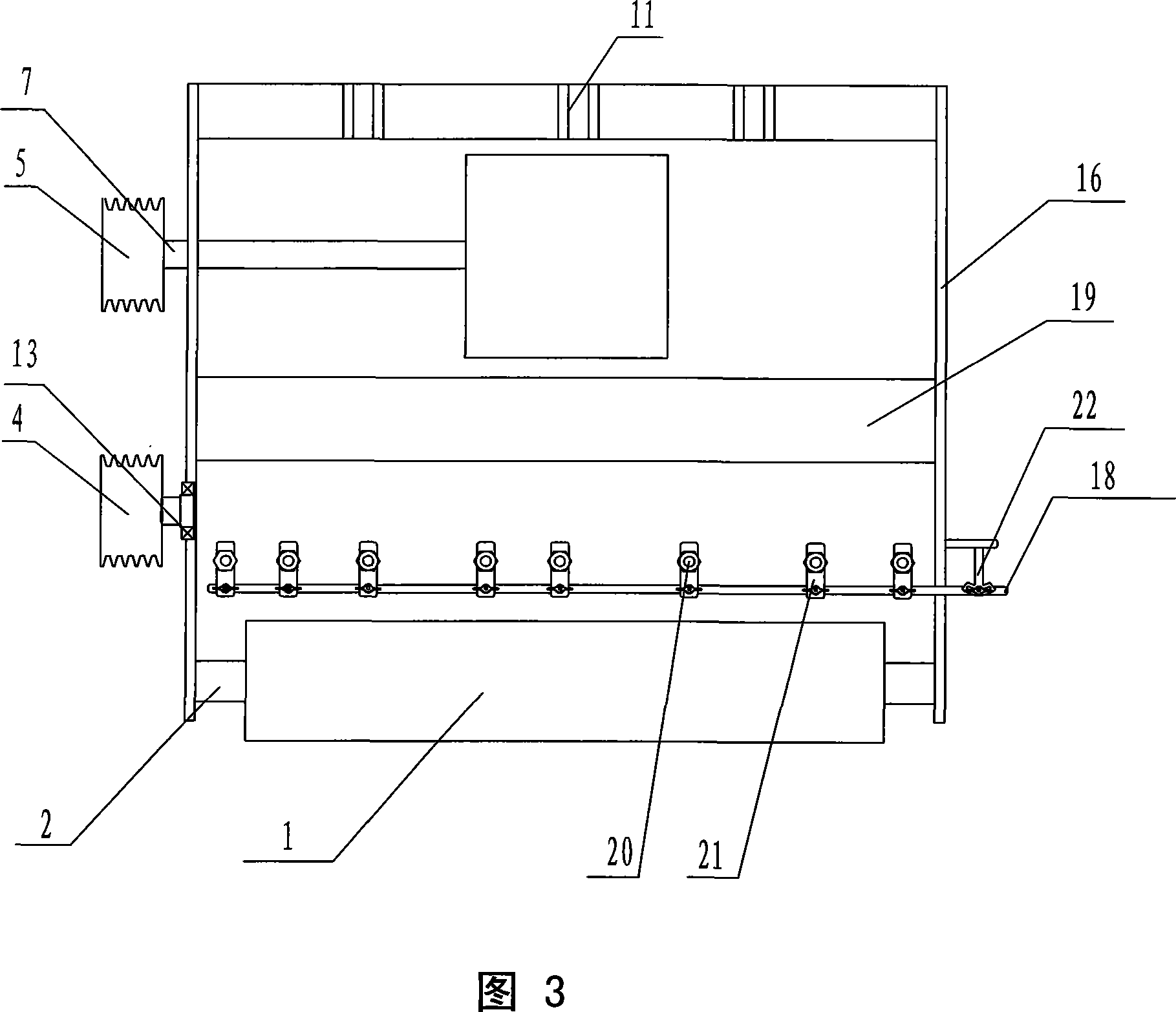

[0017] In the embodiment shown in Figures 1 to 3: both ends of the pressing wheel 1 are provided with shaft heads 2, and are installed on the rear lower part of the machine cover 19 through sliding bearings 15, and the two ends of the cutter shaft 12 are correspondingly provided with shaft heads 3 and the shaft head 14, and are installed on the frame 16 through the rolling bearing 13, the driven pulley 4 is installed at the end of the shaft head 3, and the driving pulley 5 connected with the transmission is installed on the shaft end of the gearbox output shaft 7, fixed There are 4 tool holders 10 of Y-shaped flail knife 9 evenly distributed on the cutter shaft 12 in the form of a single helix. There is a set of fan blades 6 between the tool holders 10, and the 4 fan blades 6 in each group are evenly distributed at an inclination angle of 15 degrees around the same circumference of the cutter shaft 12; The head is evenly installed on the inner side of the rear part of the hood...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inclination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com