Method and device for measuring solid particle three-dimensional concentration field and velocity field in gas/solid two-phase stream

A solid particle and concentration field technology, which is applied in measuring devices, particle suspension analysis, fluid velocity measurement, etc., can solve the problems of complex system, large equipment investment, and multi-camera system parameters that cannot be fixed, so as to overcome the complex structure and improve the recognition The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

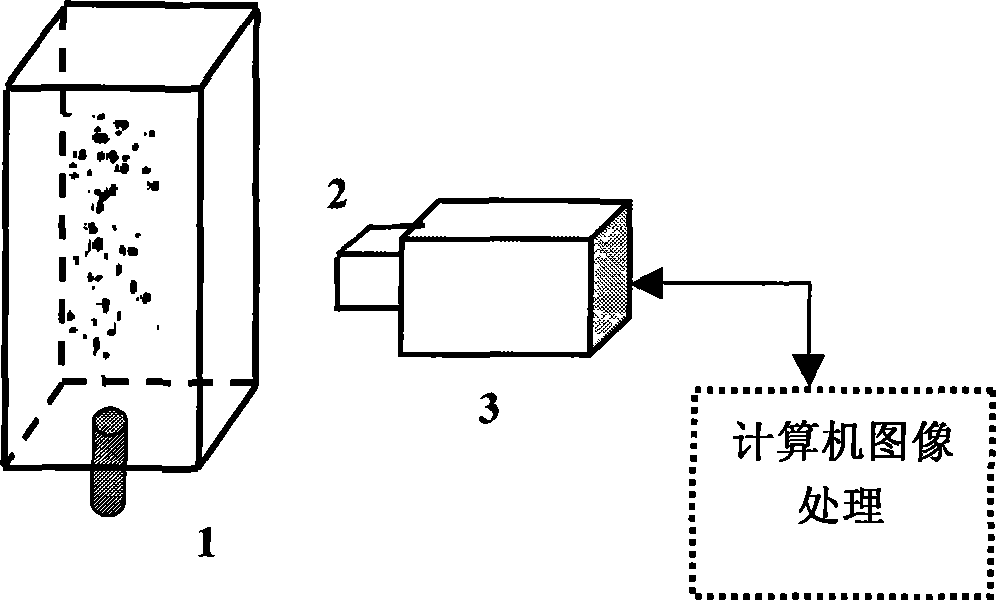

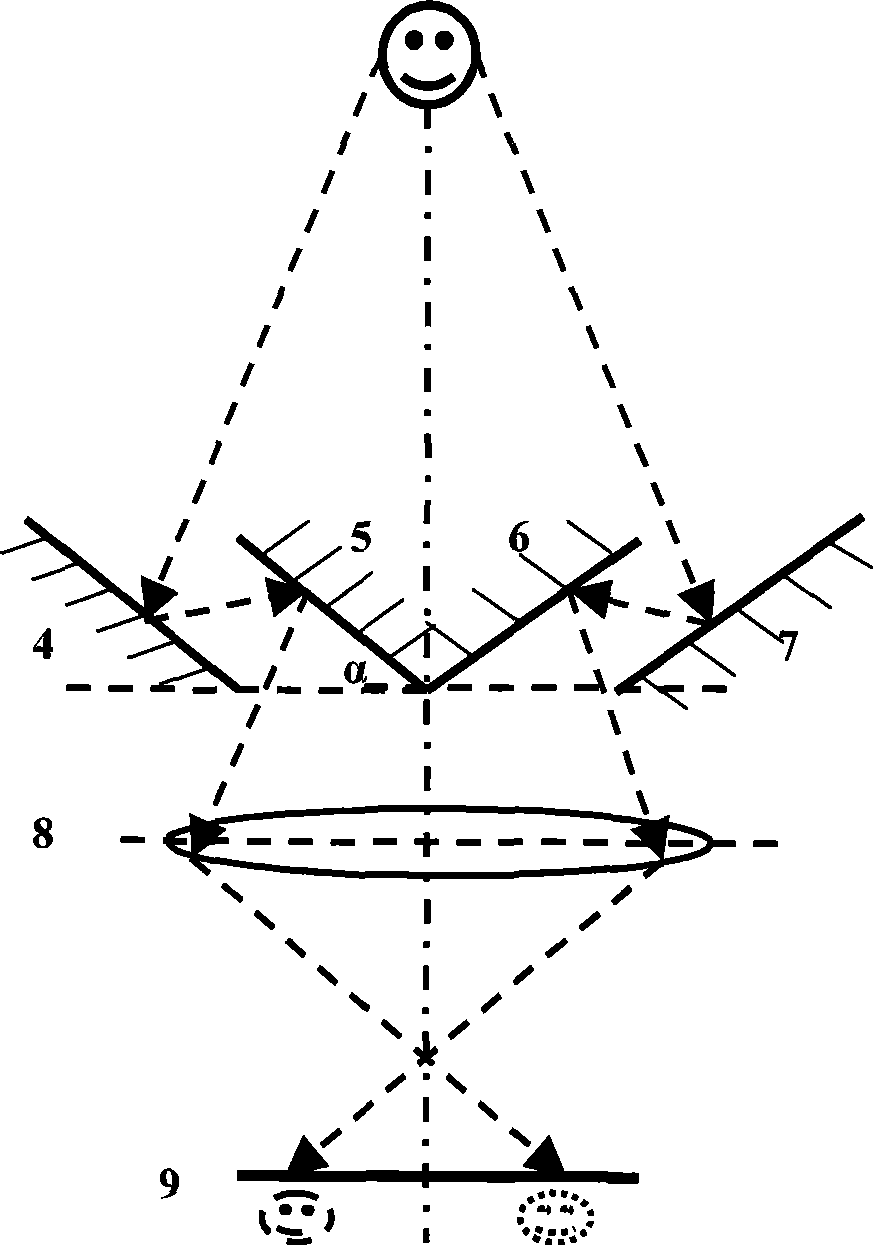

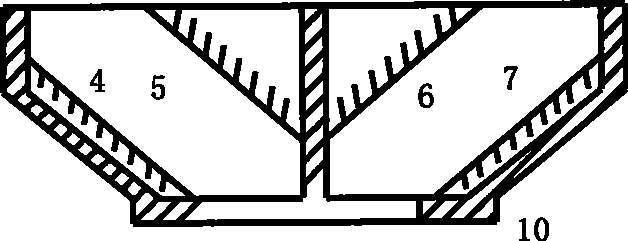

[0021] like figure 1 , figure 2 , image 3 , Figure 4 Shown, the present invention is divided into two parts of hardware system and software system, and hardware system mainly comprises three parts: be fixed on the double viewing angle stereoscopic mirror 2 before high-speed camera lens, be used for the high-speed camera 3 of collecting image and process image background computer, the two-view stereoscopic mirror 2 is placed and arranged by four plane mirrors as follows, that is, the first plane mirror 4, the second plane mirror 5, the third plane mirror 6 and the fourth plane mirror 7 are arranged in sequence from left to right , the first plane mirror 4 and the second plane mirror 5 are arranged in parallel, the third plane mirror 6 and the fourth plane mirror 7 are arranged in parallel, the first plane mirror 4 and the second plane mirror 5 are placed symmetrically with the third plane mirror 6 and the fourth plane mirror 7, the second The included angle between the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com