Cigarette package denseness on-line detection device and method

A detection device and density technology, applied in the direction of material analysis and sorting using radiation, can solve problems such as waste, failure to feedback, product destructive detection, etc., to improve the level of automation, ensure the quality of cigarette packs, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical scheme of the present invention is further described in detail below in conjunction with accompanying drawing:

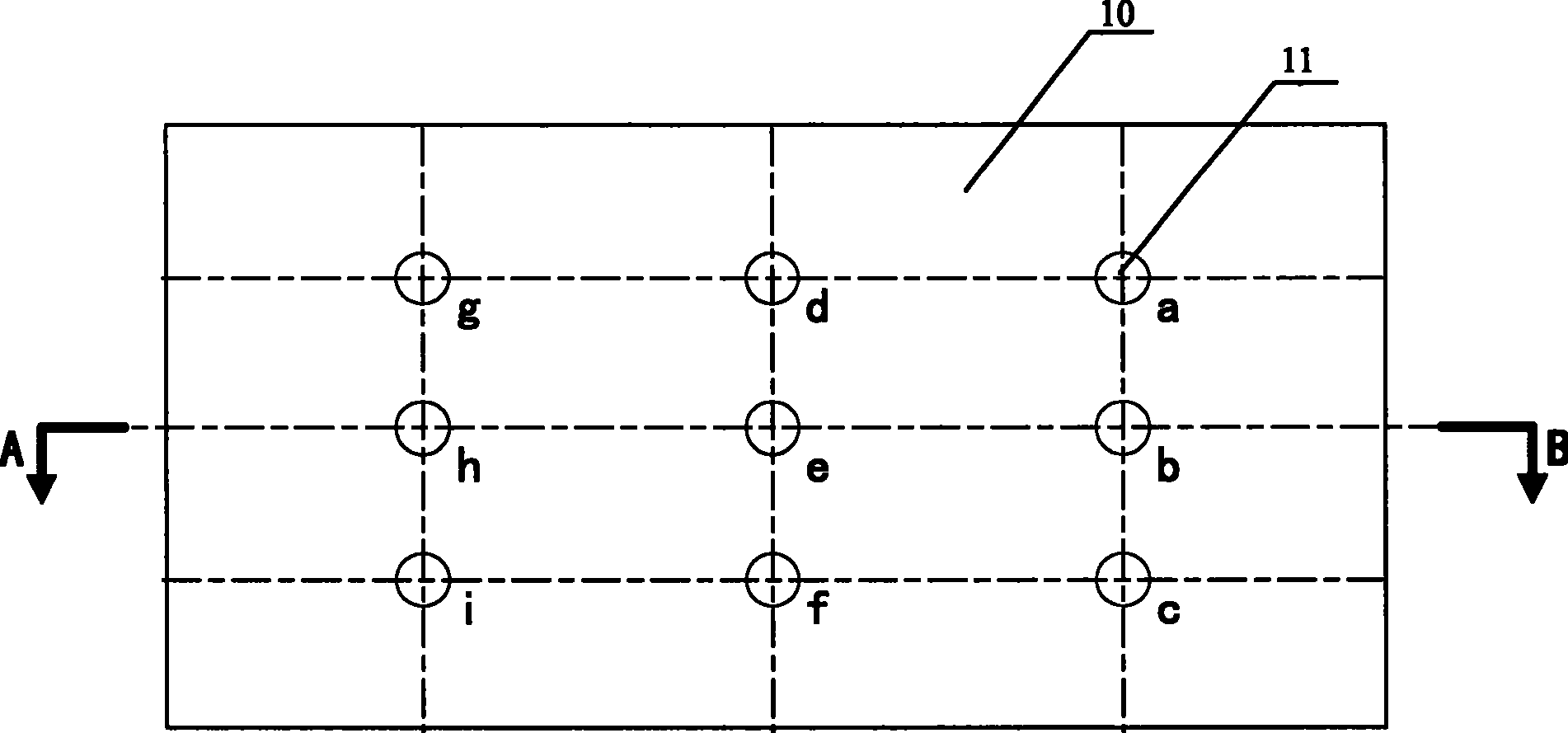

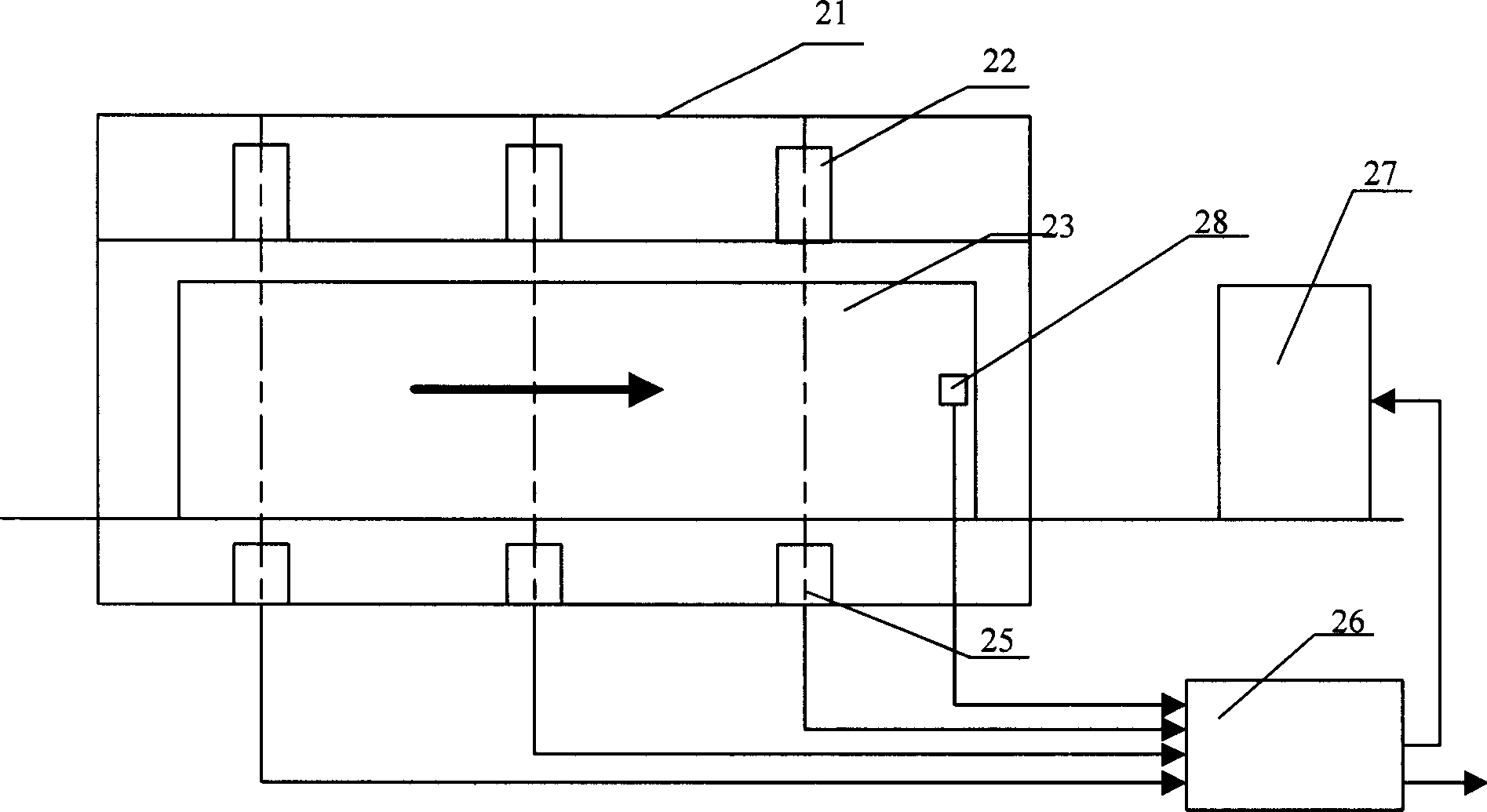

[0049] refer to Figure 2a , 2b and Figure 3a , 3b, the cigarette package density on-line detection device of the present invention comprises one or more detection units, and this detection unit comprises one or more radiation sources or X-ray source 22 and one or more detectors 25, support 21, position sensor 28 (28 ', 28 "), data acquisition and processing system 26 and rejecting device 27 (for ease of illustration, assume m radiation sources or X-ray sources and m detectors). Wherein radiation source 22 and detector 25 are respectively installed on bracket 21 On. The detector 25, the position sensor 28 and the rejecting device 27 are connected with the data acquisition and processing system 26 with a cable, and the cigarette package passes through the detection between the radiation source 22 and the detector 25. m radiation sources or X-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com