Recordable optical storage systems

A technology of optical and storage media, applied in the field of optical storage systems, can solve problems such as incompleteness, OPC failure, and long-term testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

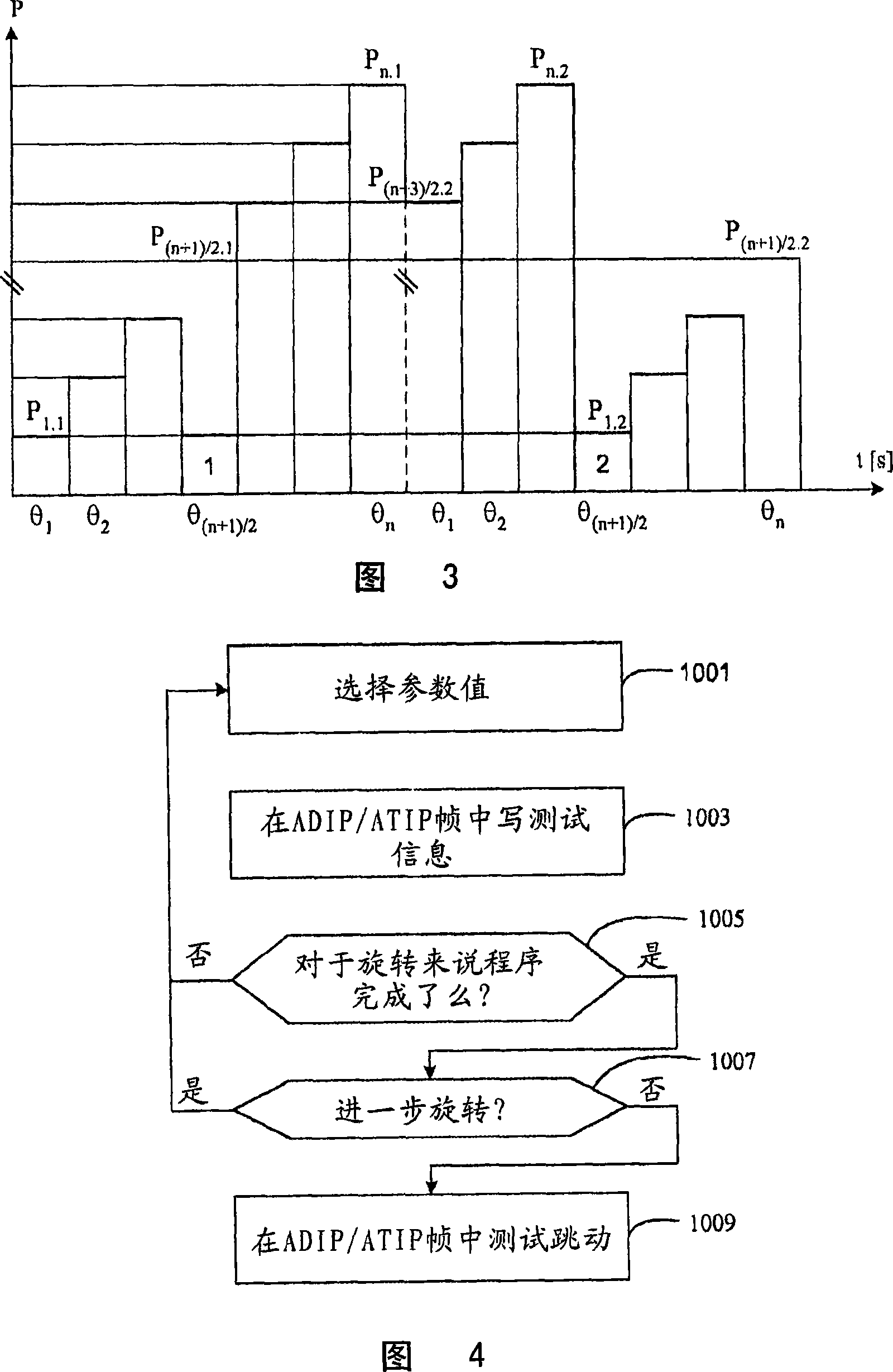

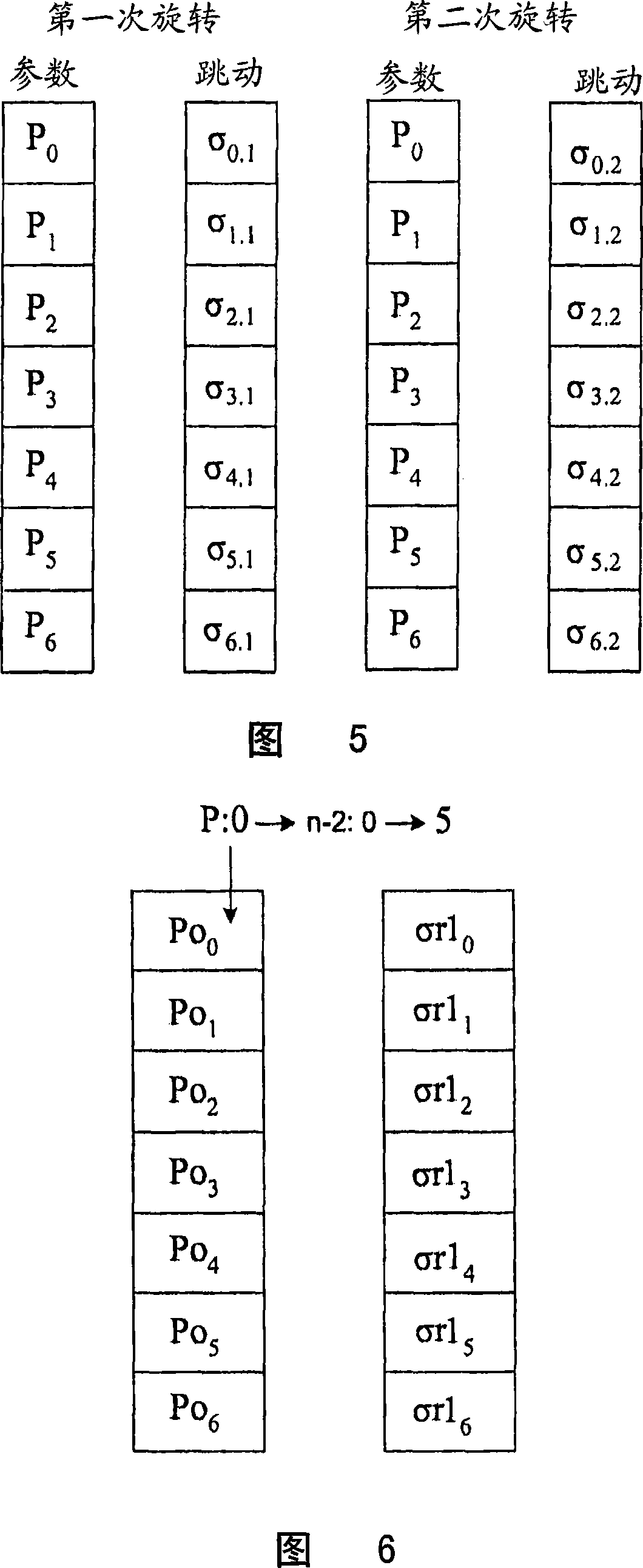

[0040] The sigma-OPC program of the present invention is executed using the test area of the disc. In order to provide fast and space-saving OPC, embodiments of the present invention utilize only two rotations of the disk to provide the sigma-OPC procedure.

[0041] Although the invention is primarily described with reference to CD-R(W) and DVD-R(W) discs, it should be understood that the invention is applicable to applications requiring optimal parameters for writing information to or reading information from the medium. any optical recording medium. For example, the present invention is also applicable to, but not limited to, DVD-R_DL, DVD-RW_DL, Blu-ray Disc, and the like.

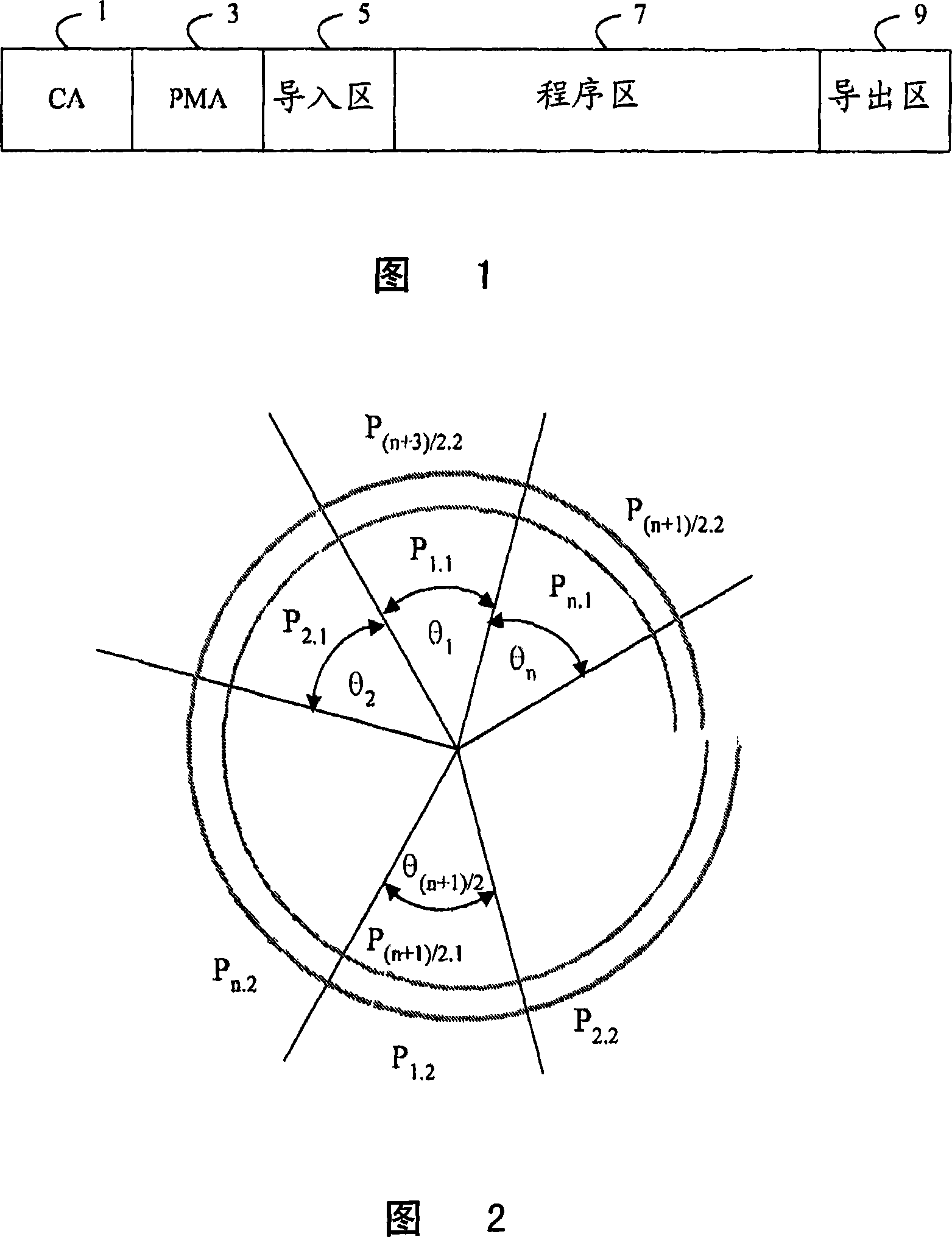

[0042] Figure 1 shows a side view of a standard CD-RW disc. The "Calibration Area" (CA) 1 defines the test area of the disc, in which area of the disc any OPC procedure normally takes place. A program memory area (PMA) 3, lead-in and lead-out areas 5, 9 and a program area 7 are provided on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com