Impinging stream reactor

An impinging flow reactor and reactor technology, applied in the field of reactors, can solve the problems of only focusing on opposing collisions, weak mixing, and difficulty in contacting fluid masses with each other, and achieve the effects of increasing turbulent intensity, strengthening mixing, and strengthening the impact process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

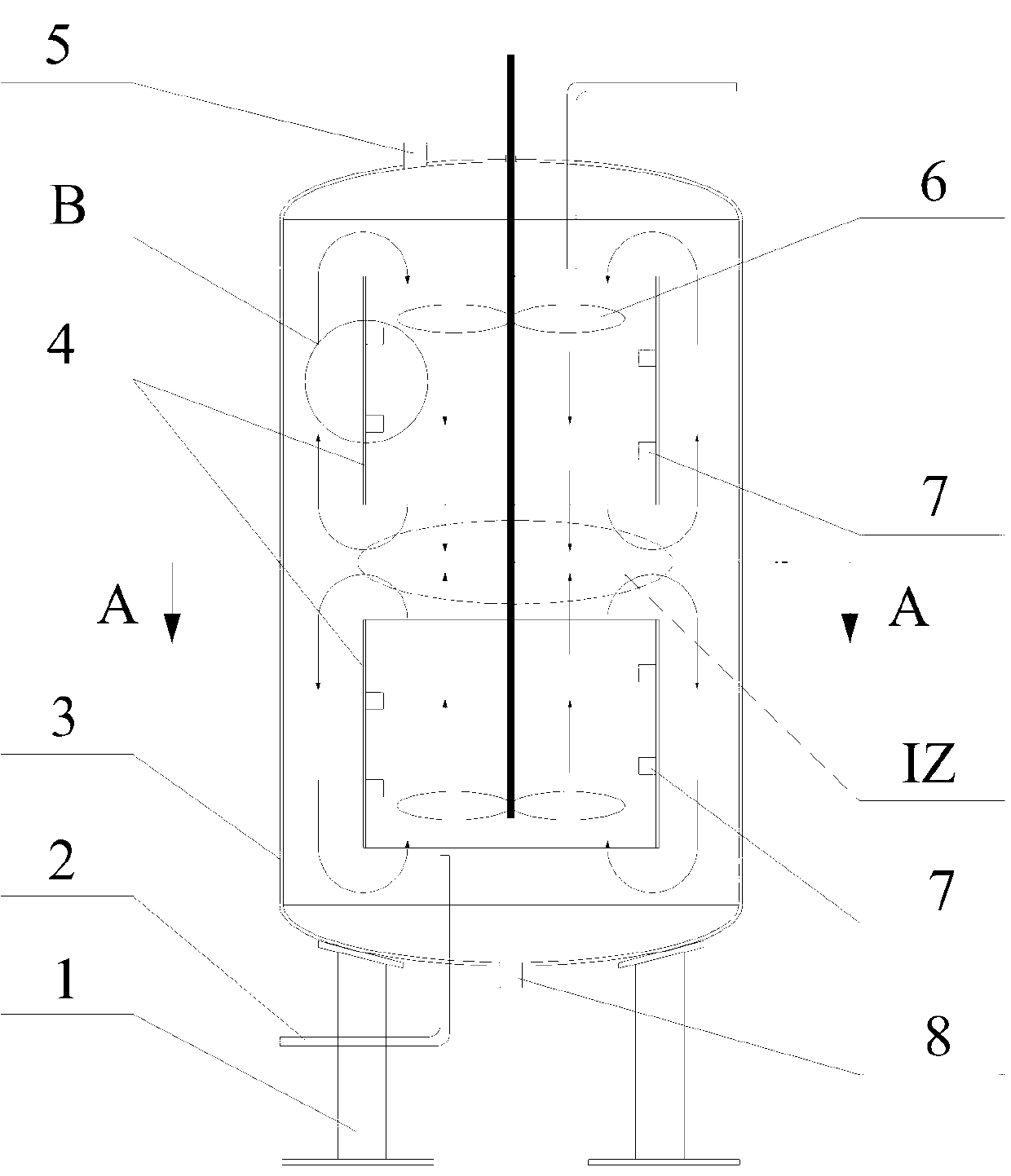

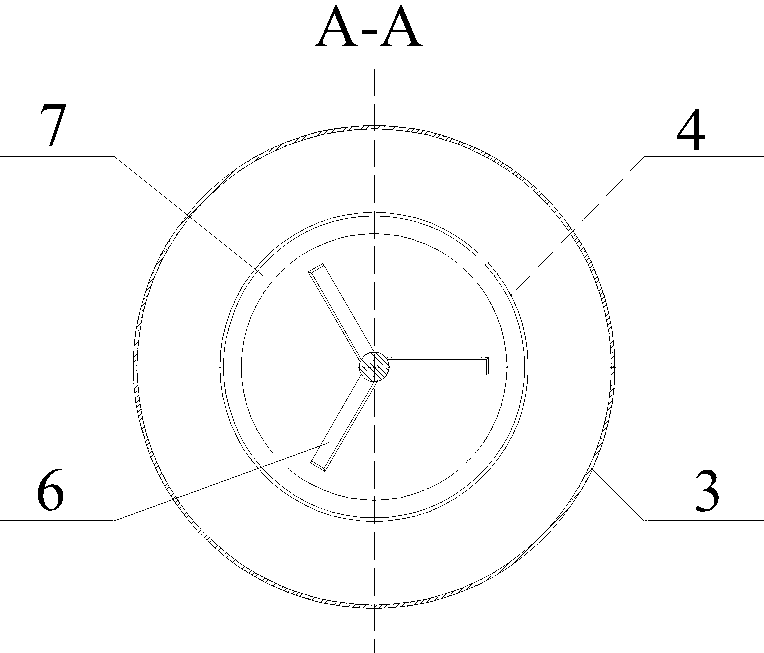

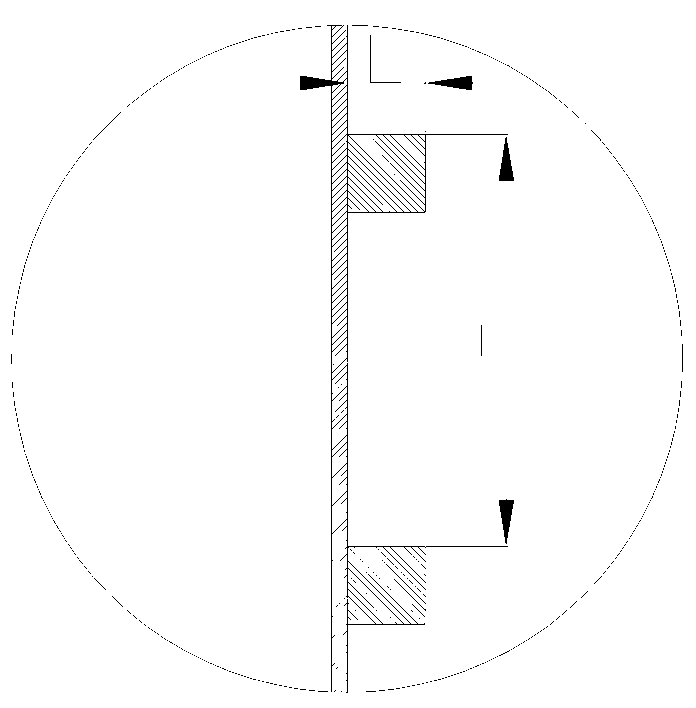

[0028] like Figure 1 to Figure 8 Shown, a kind of impinging flow reactor, it is vertical structure, and it comprises reactor support 1, cylindrical reactor 3, feed pipe 2, exhaust pipe 5, unloading pipe 8, guide tube 4 , spiral deflector 7 and propeller 6, the reactor 3 is fixed on the reactor support 1, the upper and lower ends of the reactor 1 are provided with a feed inlet, connected by the feed pipe 2, the discharge pipe 8 Installed at the lower end of the reactor 1, the exhaust pipe 5 is arranged at the upper end of the reactor 3, and two guide tubes 4 are coaxially installed at the upper and lower ends of the inside of the reactor 3, and at the top of the guide tube A fluid impact zone IZ is formed between the outlets, and two propellers 6 with opposite rotations are coaxially arranged in the guide tube 4, which are respectively used to push the fluid from the upper end and the lower end to flow to the fluid impact zone IZ through the guide tube 4, in order to To stren...

Embodiment 2

[0035] like Figure 9 , 10 As shown, the impingement flow reactor described in embodiment 2 has basically the same structure as the impingement flow reactor in embodiment 1, the difference is that it is a horizontal structure, and the feed pipe 2 is arranged at the reaction The left and right ends of the reactor 3, and the draft tube 4 is arranged at the left and right ends of the reactor 3.

[0036] In summary, the impingement flow reactor of the present invention not only retains strong microscopic mixing and continuous liquid circulation, but also strengthens the impact process and mixing outside the impact area, shortening the time for the fluid in the reactor to achieve uniform mixing , greatly improve production efficiency, and can obtain good economic performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com