Grinding and polishing machine for grinding and/or polishing workpieces in optical quality

一种光学质量、抛光机的技术,应用在磨削/抛光设备、磨削/抛光安全装置、光学平面磨床等方向,能够解决总成本高、大结构空间需求等问题,达到避免不正确测量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

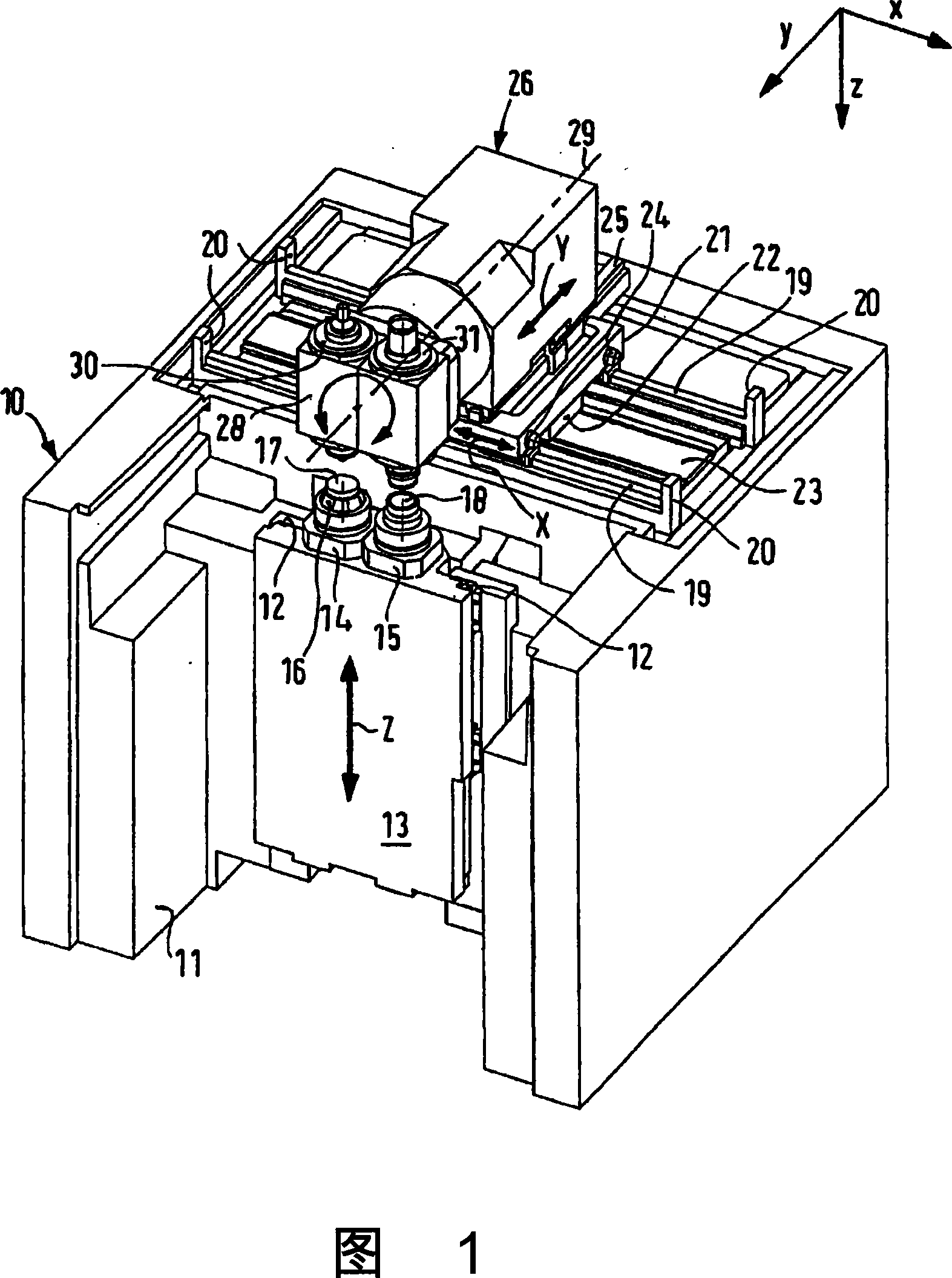

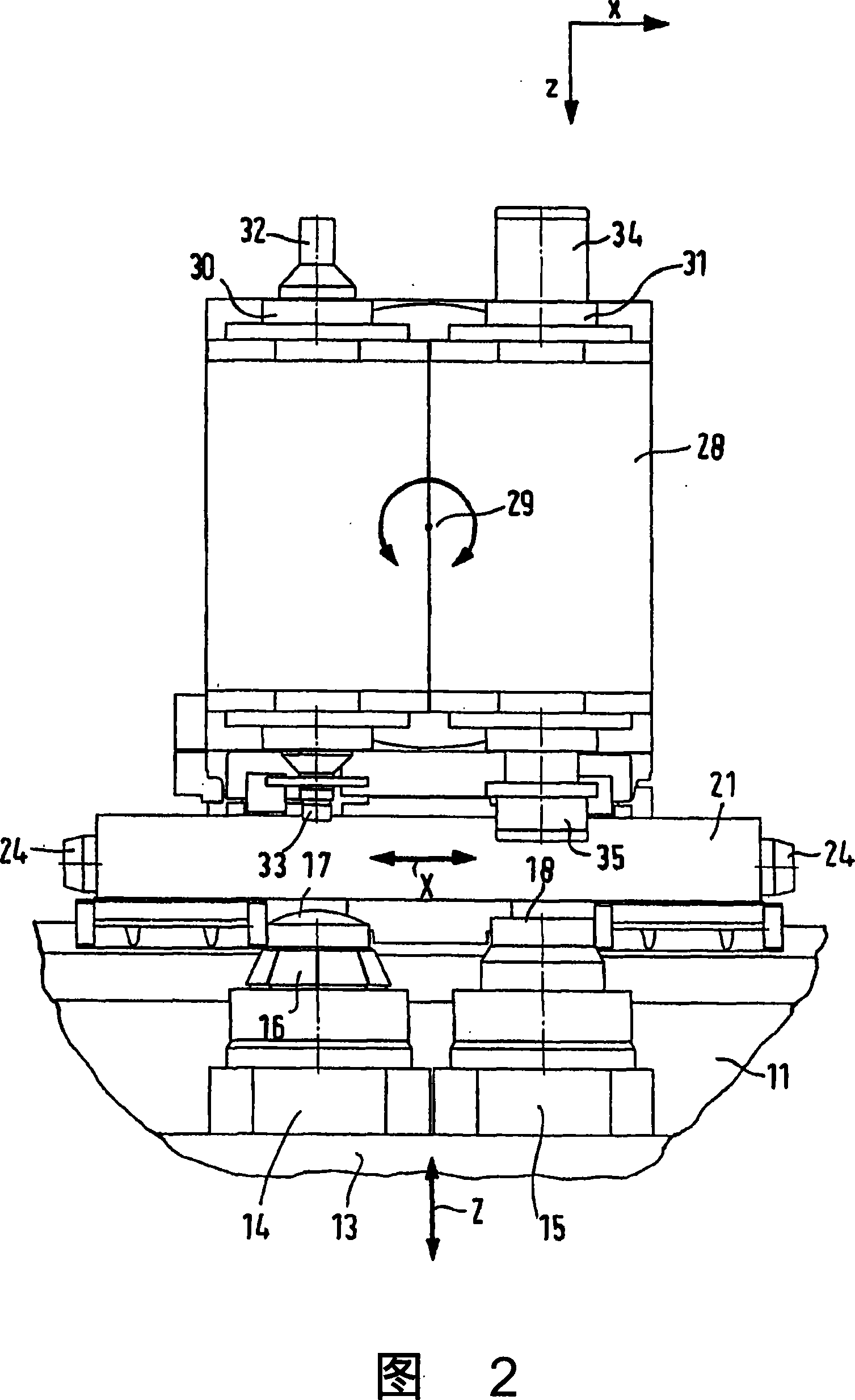

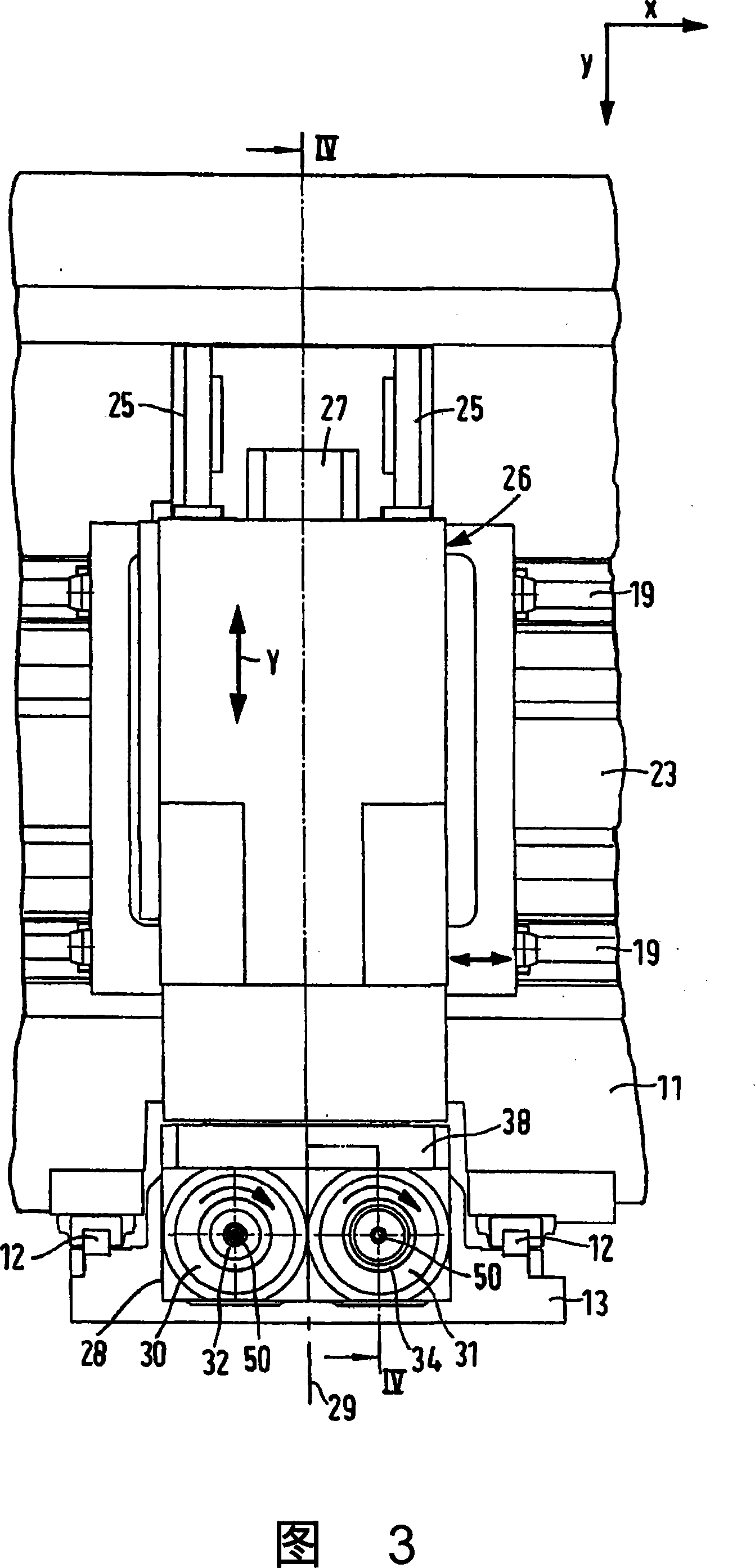

[0030] 1 shows a CNC-controlled grinding and polishing machine 10, in particular for machining optical lenses, in a Cartesian coordinate system in which the letter x designates the width direction of the machine 10 and the letter y denotes the longitudinal direction of the machine 10 , and the letter z denotes the heightwise direction of the machine 10 .

[0031]The machine 10 has a frame 11 formed from a single block of polymer concrete. Two guide rails 12 are fastened to the machine frame 11 at the front of the machine, which extend parallel to each other in the vertical height direction z. A Z-shuttle 13 movable in a CNC-controlled manner in both directions of the Z-axis by means of associated CNC drives and control elements (not shown) is mounted on the guide rail 12 so that it can be moved via Guide the carriage to shift.

[0032] On the Z-shuttle 13 there are two workpiece spindles 14 and 15 which are arranged parallel to each other and whose angular position relative ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com