Device for forming a jacquard type shed, a loom fitted with such a device, and a method of forming the shed on such a loom

A shed and pattern technology, applied to jacquard machines, looms, and other shedding mechanisms, can solve the problems of long adjustment time and high precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

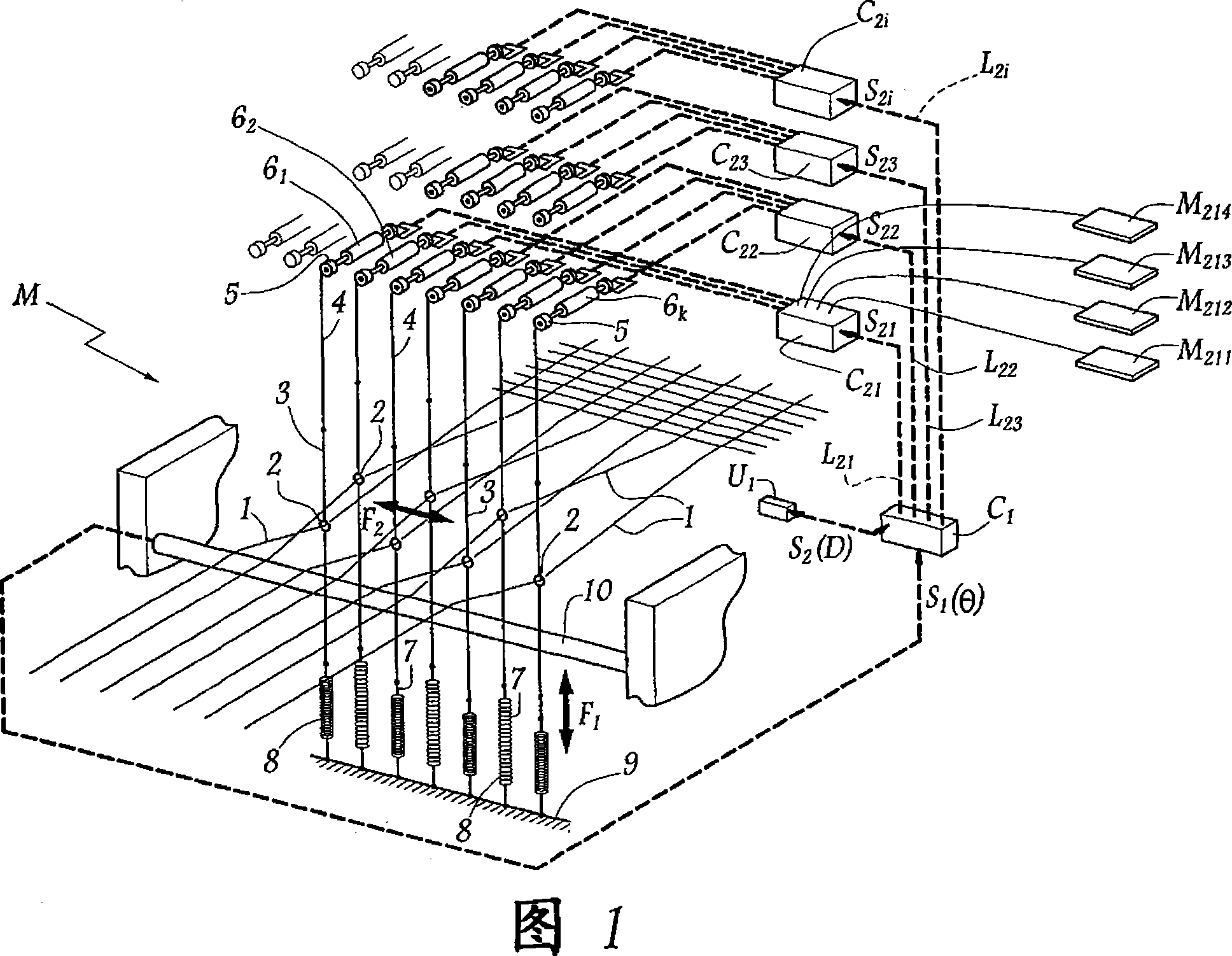

[0028] The loom M shown schematically in Fig. 1 is equipped with warp threads 1, each of which passes through the 1 Indicates) the eyelet 2 of the driven heddle 3, the reciprocating movement is generally perpendicular to the direction in which the weft yarn is engaged in the shed (the direction indicated by the double arrow F 2 express). Each heald is connected by a harness 4 to a pulley 5 driven in rotation by an electric servomotor 6 forming the actuator of the pulley 5 . At the bottom of the healds, each heald 3 is connected by a rod 7 to a return spring 8 fixed to a structure 9 of the loom M.

[0029] In practice, the number of actuators 6 in the loom M may be 12,000 or more.

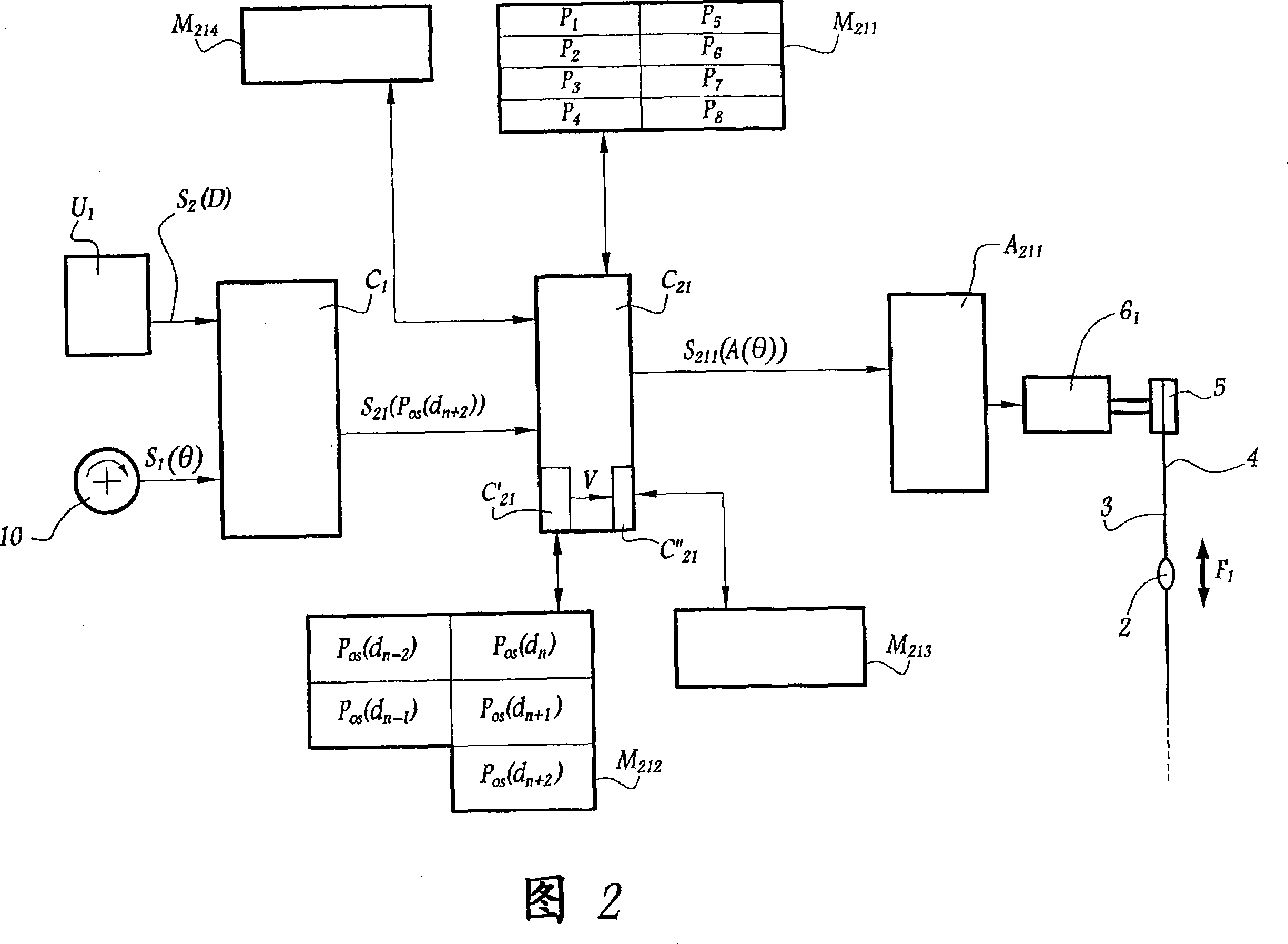

[0030] To control all or some of the actuators 6 a central computer C is used 1 and multiple remote computers C 21 , C 22 , C 23 ,...,C 2i , where the value of i is adapted to the number of actuators 6 . each computer C 21 Or an equivalent computer is arranged in the vicinity of the servo m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com