Cutting technique of packer

A cutting technology and packing machine technology, which is applied in the field of packing machinery, can solve the problems of workpiece damage, supporting design that is not conducive to diversified functions, inconvenient maintenance and replacement, etc., and achieve the effect of easy maintenance and replacement, ingenious conception and reasonable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

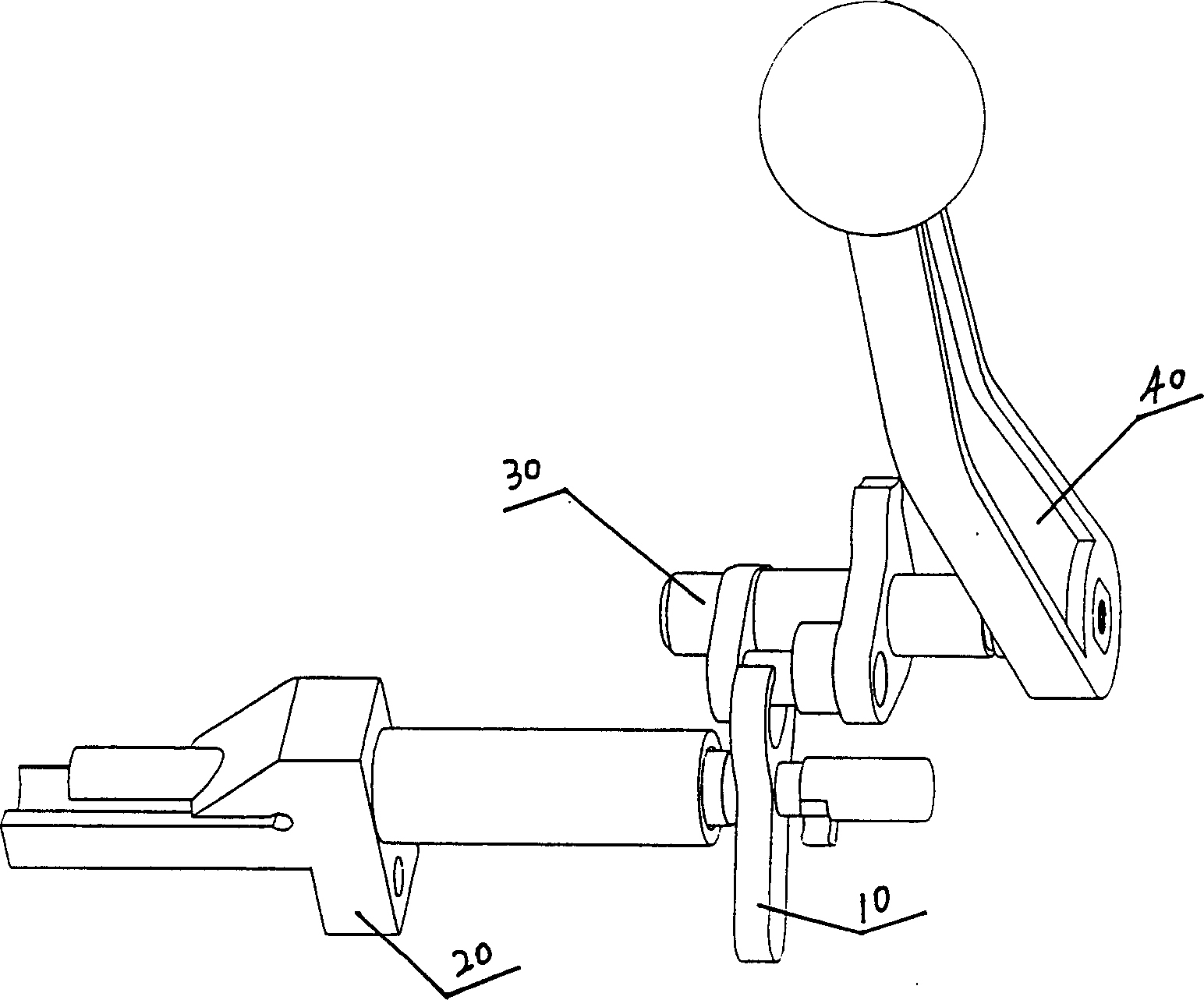

[0008] A cutting technique for a baler, which mainly includes the following steps: A. providing a cutting knife, which is set on the cutting knife holder, and the cutting knife is connected with the camshaft through a shift fork; B. providing a camshaft, and its shaft end provides Has cut strap handles. The structure of the cutting mechanism of the baler manufactured by the present invention will be described in further detail below in conjunction with the accompanying drawings. Referring to accompanying drawing, a kind of cutting mechanism of packing machine, cutting knife 10 is arranged on cutting knife frame 20, and cutting knife 10 is connected with camshaft 30 by shift fork, and the shaft end of camshaft 30 is covered with cutting handle 40. When it is matched with the baler, it is only necessary to fix the cutter frame on the bottom plate of the baler and make the camshaft pass through the wall plate of the baler. Since the mechanism is an independent mechanism, once th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com