Roof natural-ventilation deduster

A technology of natural ventilation and dust collector, applied in chemical instruments and methods, solid separation, separating solids from solids with airflow, etc., can solve the problem of shortening the service life of factory buildings, destroying the production and living environment of human beings, and affecting the production efficiency of enterprises and other issues, to achieve the effect of high social value, low maintenance cost and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

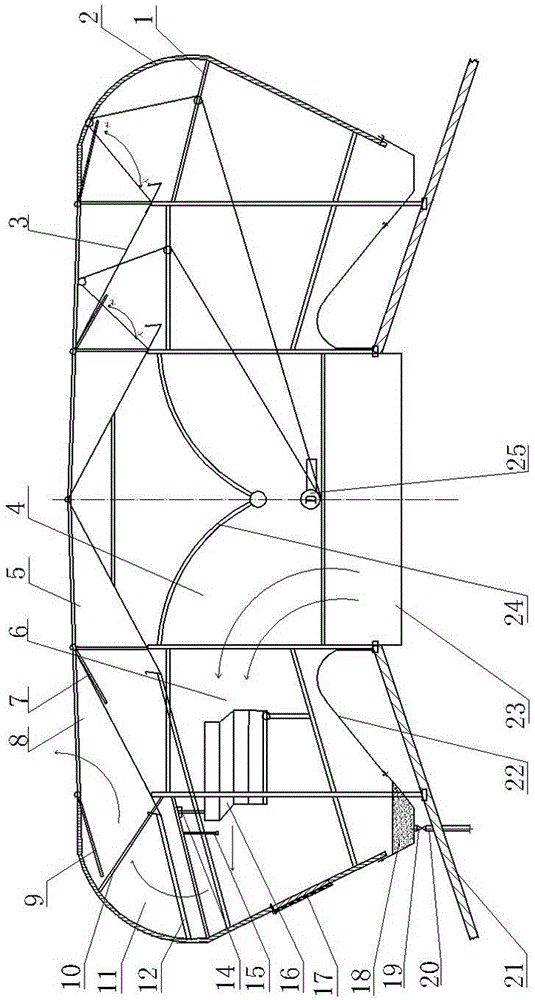

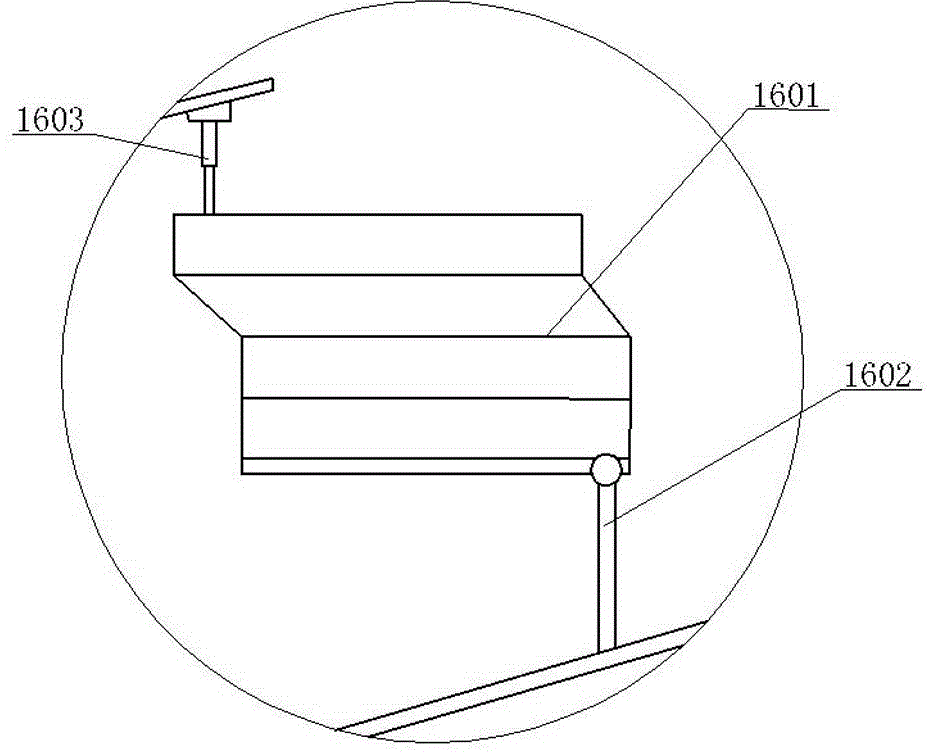

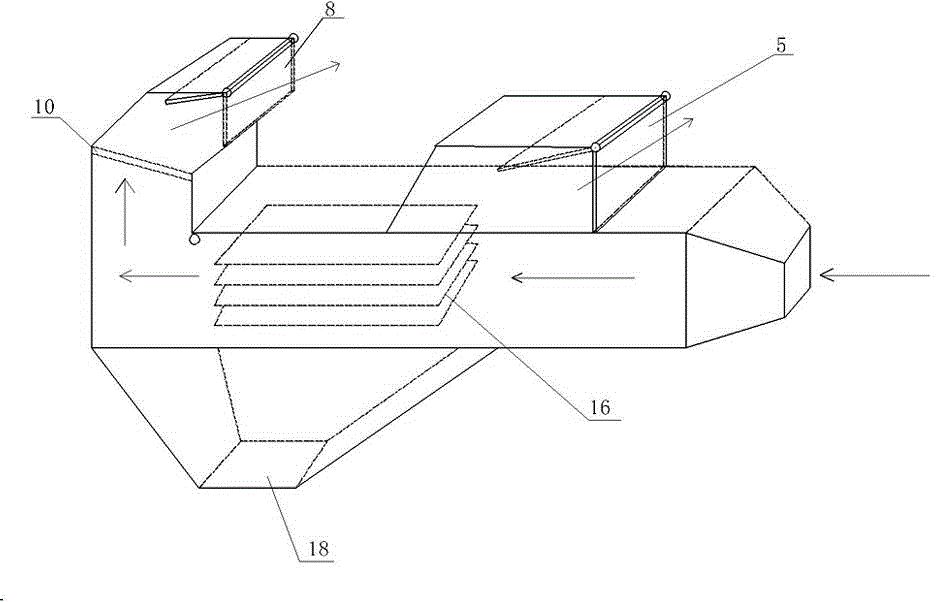

[0027] like Figure 1 ~ Figure 4 As shown, the roof natural ventilation deduster includes roof supports 1, and the roof supports 1 are in multiple groups, and one group is arranged at intervals of 3 to 3.5 meters along the longitudinal direction of the roof. An outer guard plate 2 is provided on both sides and ends of the roof support 1, a sloping floor 22 is provided at the bottom of the roof support 1, a ventilation outlet 5 is provided on the top of the roof support 1, and a roof vent is provided at the bottom of the roof support 1 23. An electric switch mechanism 25 is provided on the roof bracket 1, and the electric switch mechanism 25 adopts a wire rope traction machine (an electric linkage mechanism can also be used). The position adjacent to the outside of the ventilation outlet 5 on the roof bracket 1 is provided with a dust removal outlet 8, and the ventilation outlet 5 and the dust removal outlet 8 on the top of the roof bracket 1 corresponding to the two sides of t...

Embodiment 2

[0031] like Figure 5As shown, a drainage hole 13 communicating with the drainage groove 12 is provided at the position corresponding to the drainage groove 12 on the outer guard plate 2, so that the accumulated water flowing through the drainage groove 12 is directly drawn out from the drainage hole 13, and when rain or snow occurs Sometimes the rain and snow falling on the rain shield 3 are discharged through the drainage hole 13 with the drainage groove 12 and do not fall into the dust collection groove 18, so as to facilitate the recovery and reuse of dust.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com