Fire-preventing check valve

A check valve and fire damper technology, applied in the field of fire check valves, can solve problems such as unsatisfactory use effect, complex structure, heavy weight, etc., and achieve good fire prevention effect, good effect and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

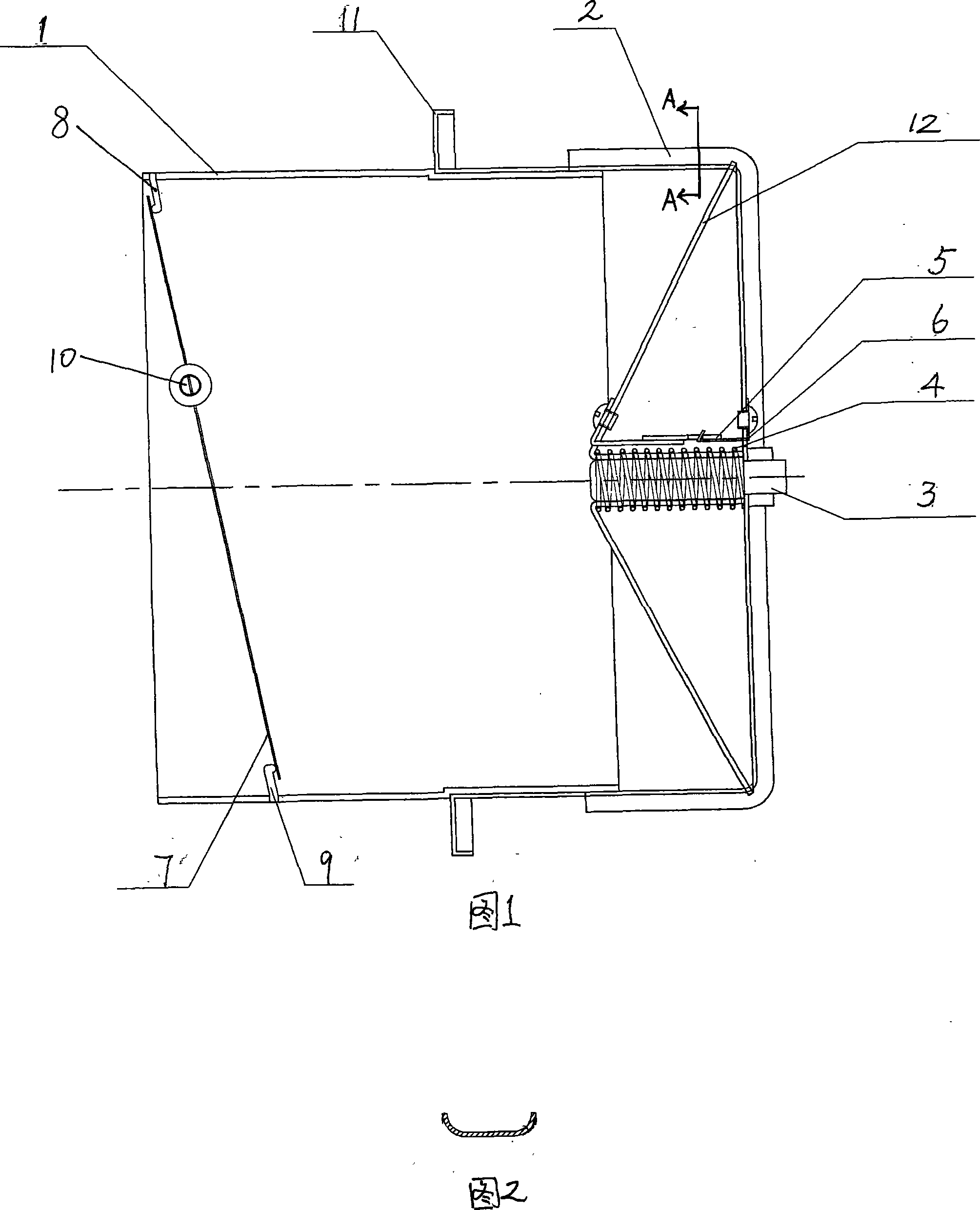

[0015] A fire check valve comprises a check valve pipe 1, a check valve device is arranged at the air inlet end of the check valve pipe 1, and a fire valve device with a spring-controlled opening and closing is arranged at the air outlet end of the check valve pipe.

[0016] The spring-controlled opening and closing fire damper device includes a guide shaft 3 arranged on a bracket 2, the bracket 2 is connected to the gas outlet end of the check valve pipe 1, a spring 4 is set on the guide shaft 3, and a fireproof valve can close the check valve pipe. The central part of the door 12 is inserted between the spring 4 and the guide shaft 3, and the free end of the central part of the fire door is connected to one end of the temperature control fuse 5, and the other end of the temperature control fuse 5 is connected to the spring fixed on the bracket 2 Hook 6 connection. The fire door is umbrella-shaped (or semi-circular, spherical and other suitable shapes). The check valve devic...

Embodiment 2

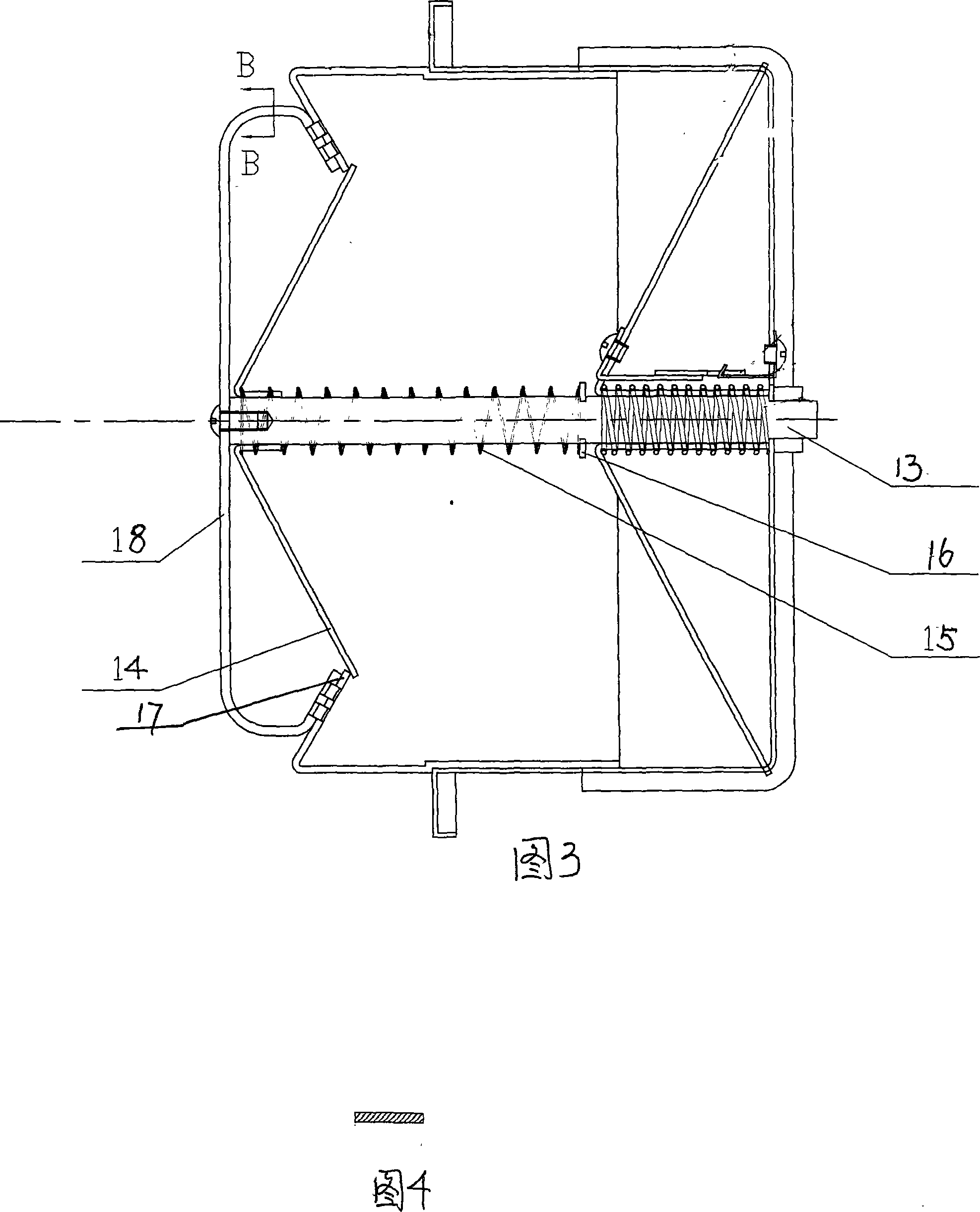

[0019] The check valve device includes a guide shaft 13, a spring 15 with one end of the front end of the guide shaft 13 in contact with the inner side of the check valve umbrella door (or semicircular, spherical, etc.) 16, the edge of the check valve umbrella is in contact with the inside of the windshield positioning protrusion 17 that is fixedly connected with the check valve pipe. The front end of the guide shaft is fixed on the axial cage 18 . When the range hood is on, the check valve umbrella door opens, and when the range hood is off, the umbrella door closes the valve under the thrust of the return spring. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com