Watertight zip fastener

A watertight zipper and sprocket technology, applied in the field of zippers and watertight zippers, can solve the problems of zipper damage, easy falling off of inner sprockets, easy displacement of outer sprockets, etc., to achieve stable and reliable sealing performance, reliable sealing performance and service life. Guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

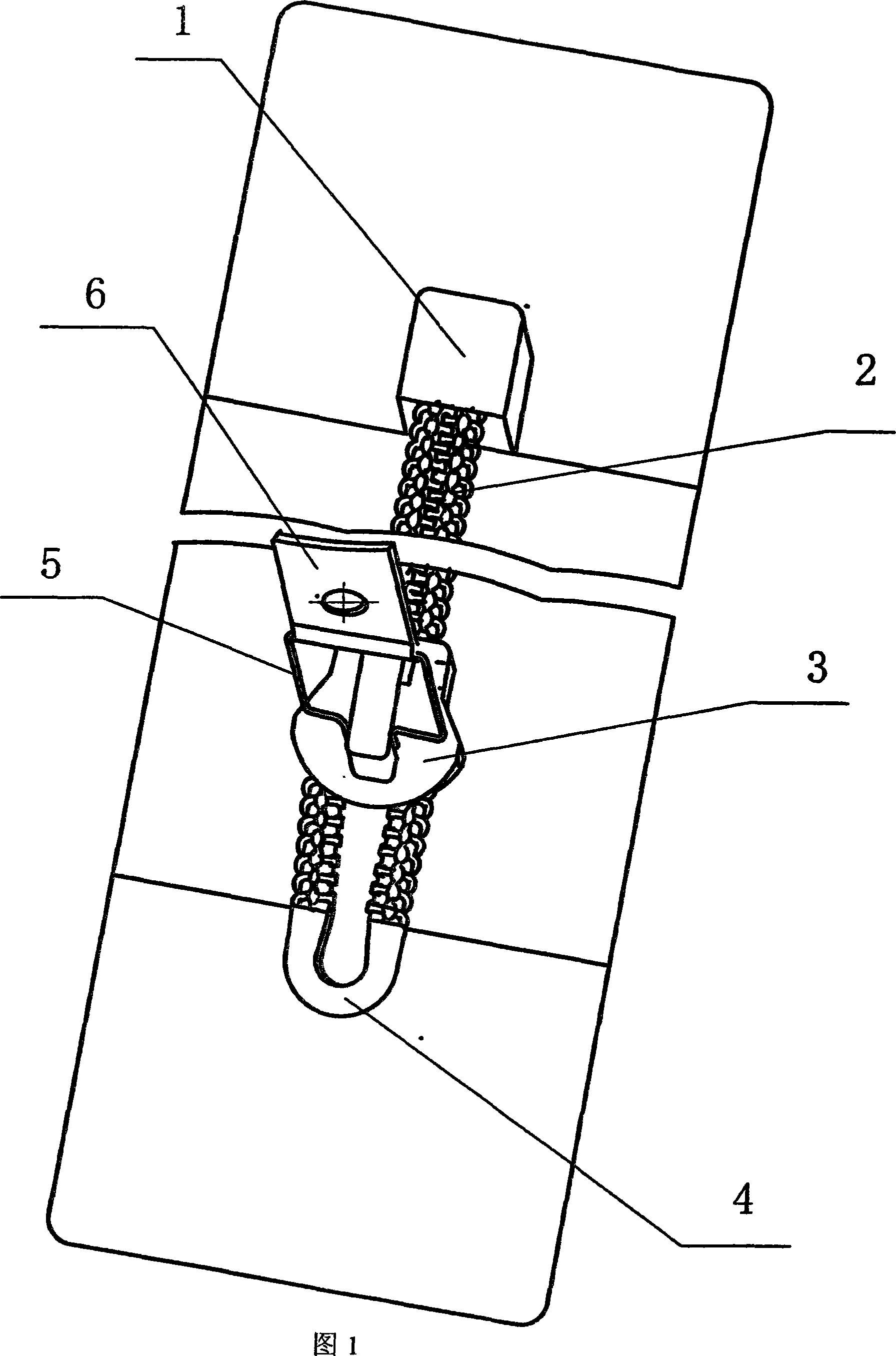

[0023] Referring to FIG. 1 , the present invention is a watertight zipper mainly composed of a head I1 , a head II4 , a sprocket belt 2 and a slider 3 .

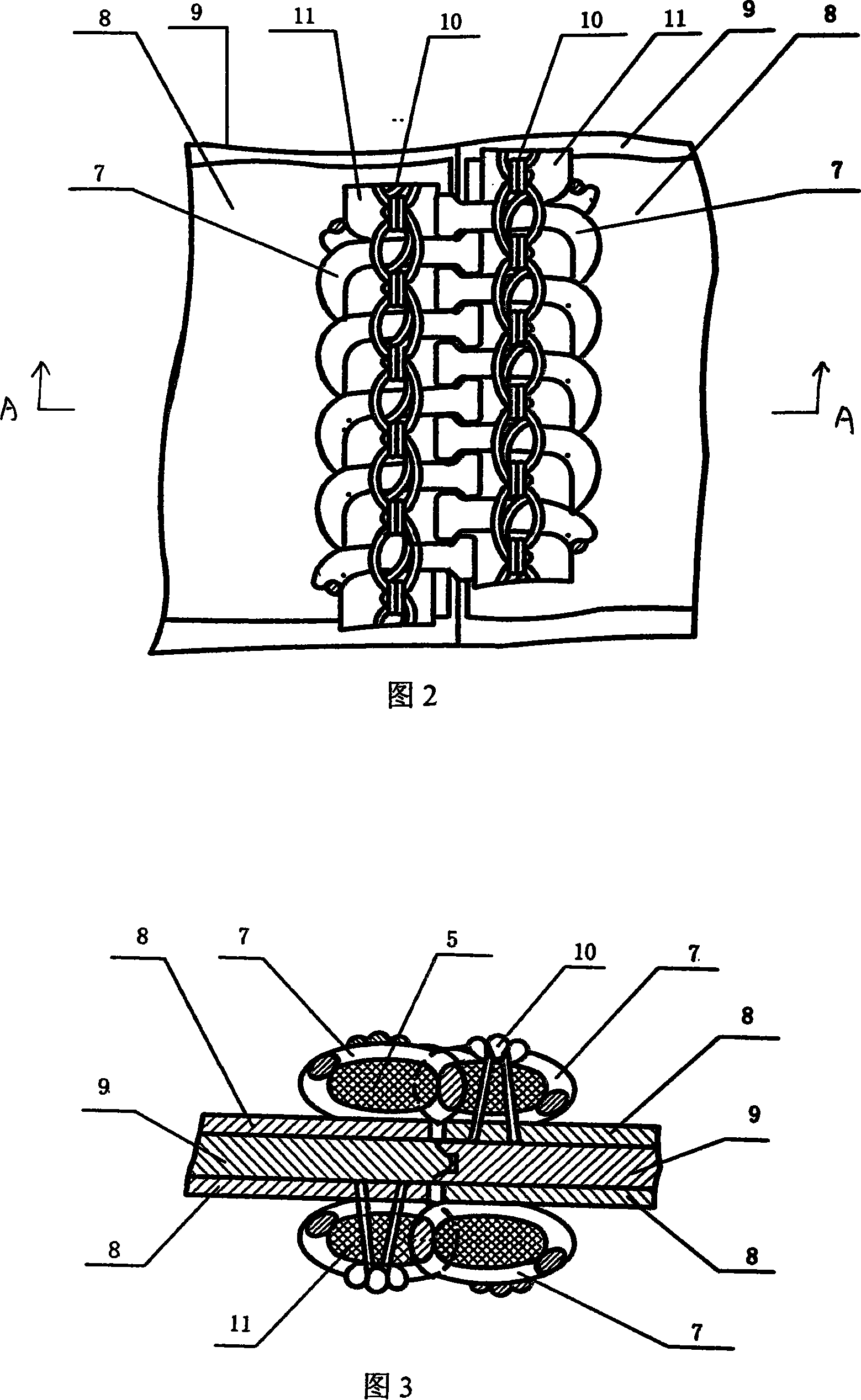

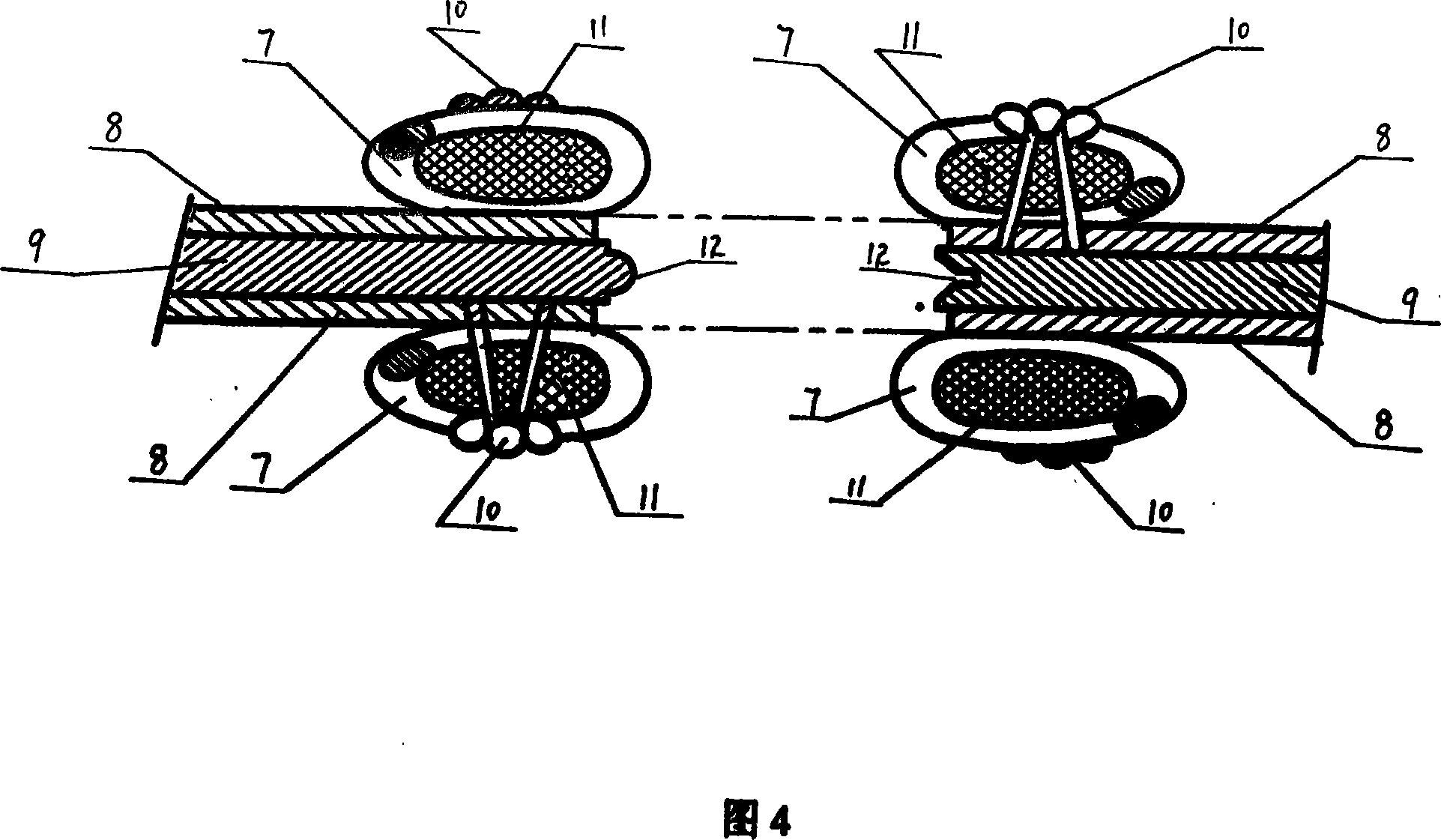

[0024] As shown in Figures 2 and 3, the sprocket belt 2 is composed of upper and lower pairs of sprockets 7 and a middle pair of sprocket belts 8 . First of all, use nylon, polyamide, polyethylene and other synthetic resin single fibers to make linear ring-shaped chain teeth 7, and use a core wire 11 to pass through and fill in the chain teeth 7; the chain belt 8 has two upper and lower parts. A layer of sealing tape 9 made of soft sealing material is sandwiched between the upper and lower layers of chain belts 8, and the three layers are pressed together; the legs (middle) of the chain teeth 7 are sewn with sewing thread 10 On the surfaces of the upper chain belt 8 and the lower chain belt 8, the chain tooth belt 2 of the slide fastener is formed. Then, divide the upper and lower pairs of sprocket belts to the left and rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com