Electric resistance type touch screen control circuit

A control circuit and touch screen technology, applied in the direction of electrical digital data processing, instrumentation, data processing input/output process, etc., can solve the problems of gain error, offset error and gain error, touch screen cannot be displayed on the full screen, etc., to reduce Chip power consumption and chip area, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

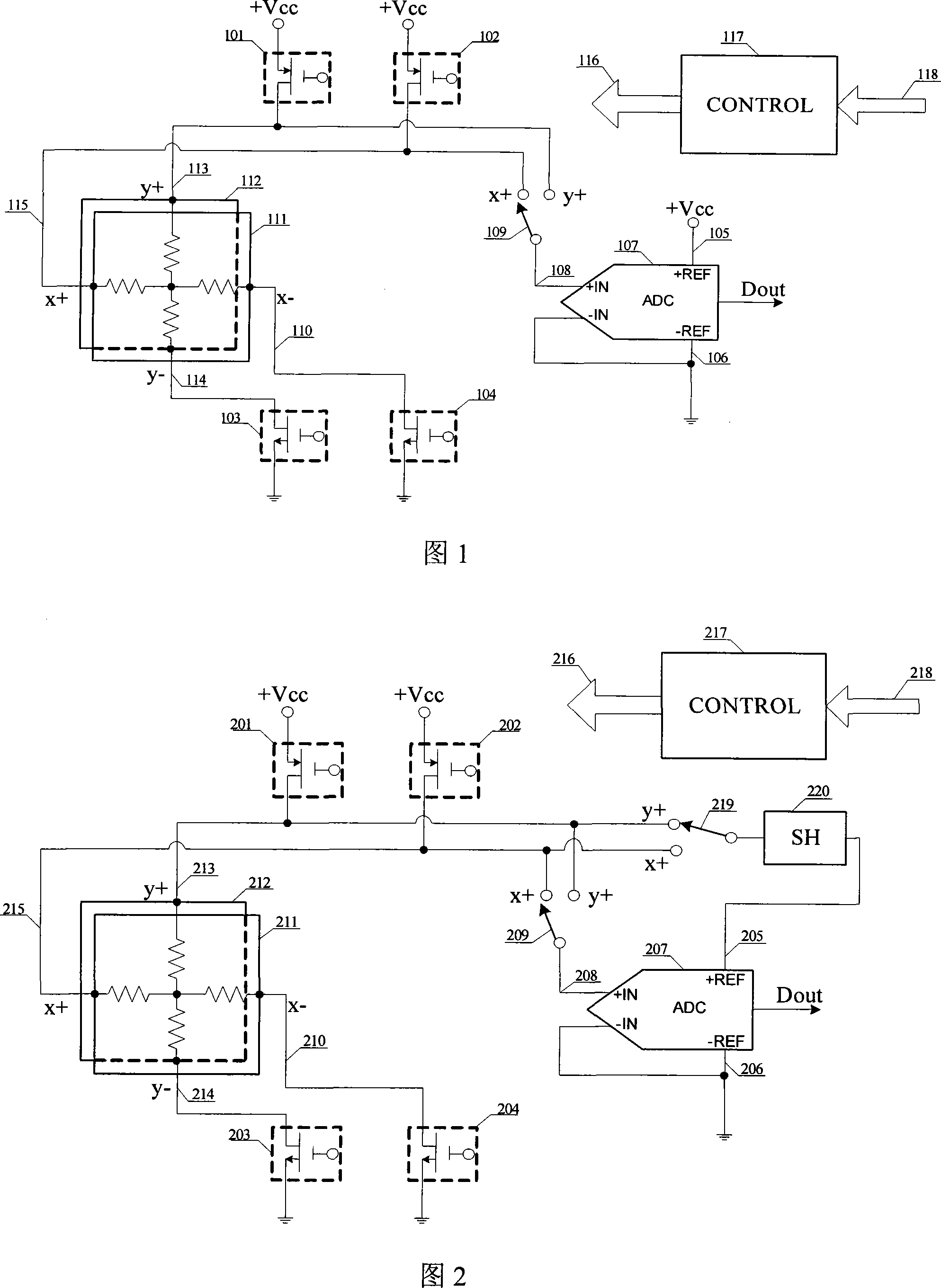

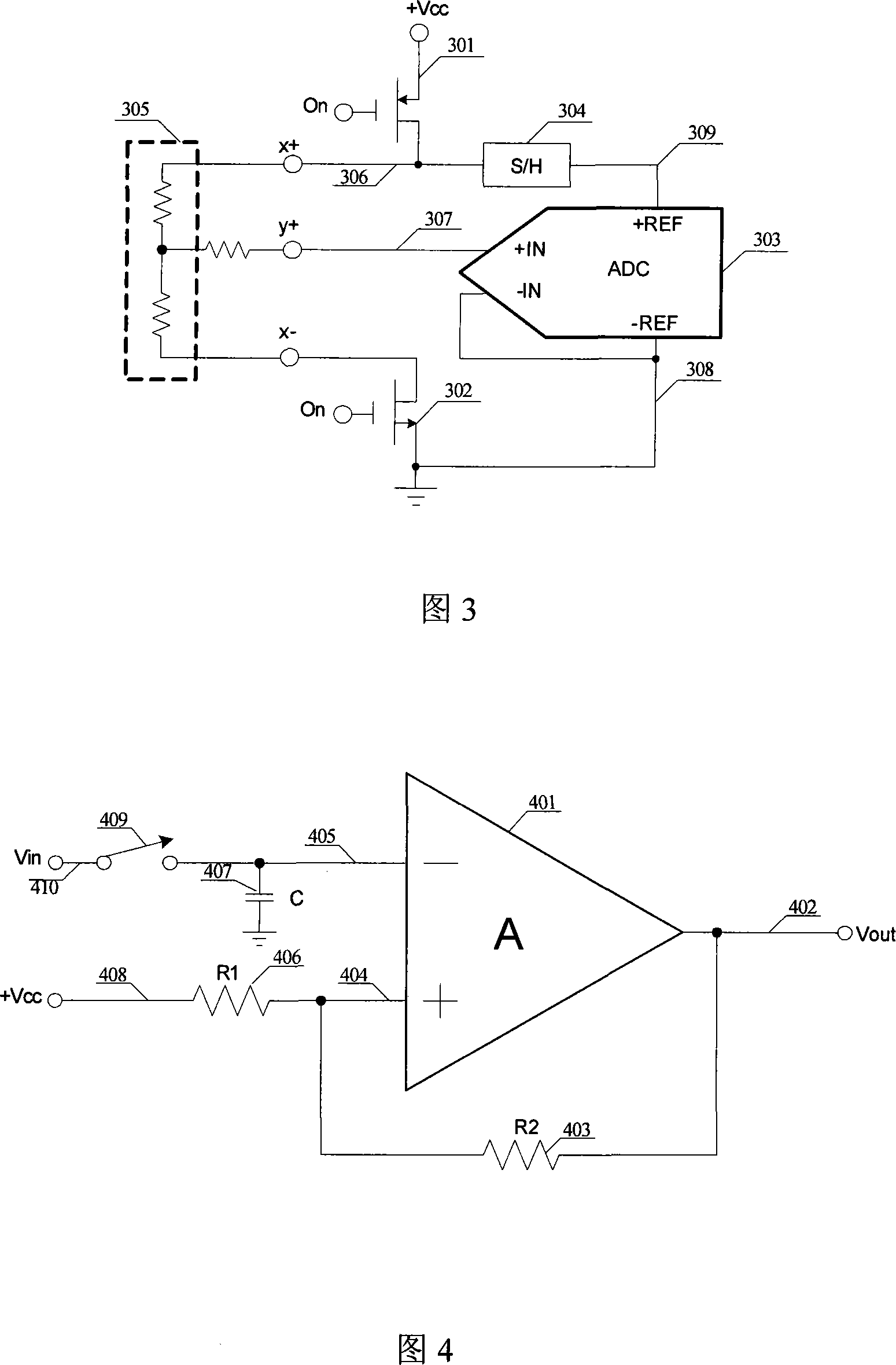

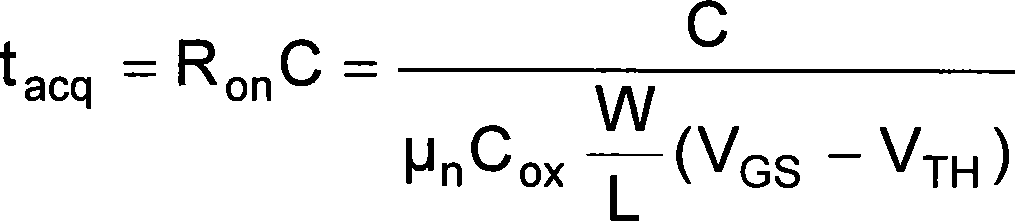

[0026] The circuit composition and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. For ease of understanding, the descriptions in the following embodiments are mainly based on four-wire resistive touch screens, but the principles are also applicable to all different types of touch screens, such as five-wire resistive touch screens, seven-wire resistive touch screens and eight-wire resistive touch screens. In addition, parts of the present invention that are the same as or similar to the prior art will not be further described in detail, and these parts are well known to those skilled in the art.

[0027] FIG. 2 is a schematic diagram of an embodiment of the resistive touch screen control circuit of the present invention. As shown in the figure, the resistive touch screen control circuit includes resistive touch screens 211, 212, driving tubes 201, 202, 203, 204 connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com