Anode of high-temperature lithium thionyl chloride battery and its making method

A lithium thionyl chloride battery and positive electrode technology, which is applied in electrode manufacturing, active material electrodes, etc., can solve the problems of high saturated vapor pressure and low boiling point, and achieve the effect of large pulse current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

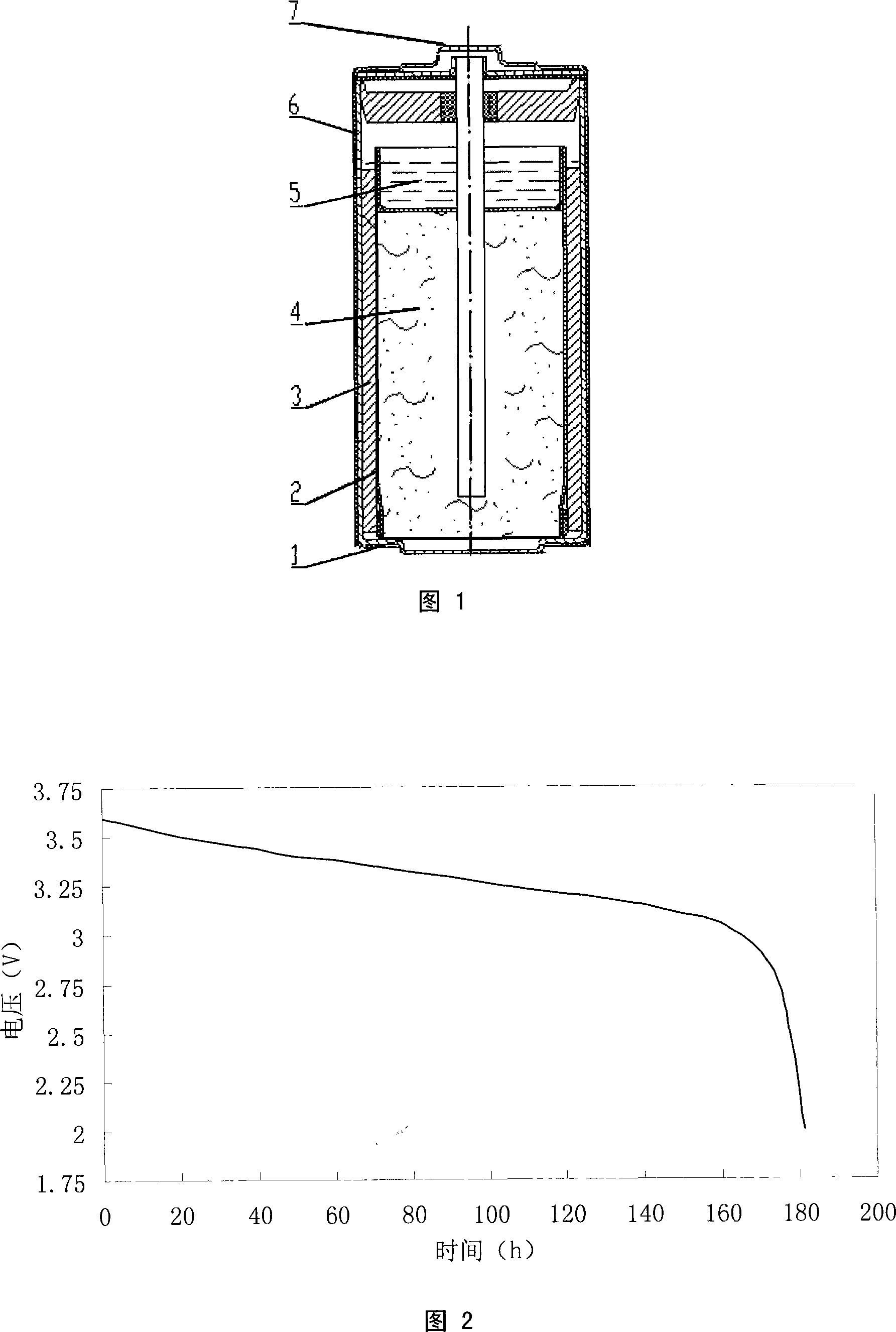

Embodiment 1

[0028] The positive electrode preparation method of high temperature lithium thionyl chloride battery:

[0029] The total process: kneading powder→molding→drying→foaming

[0030] 1) and powder:

[0031] Take materials according to the formula, positive electrode formula:

[0032] Acetylene black (battery grade): 10g;

[0033] PTFE emulsion (60% water emulsion, density 1.5g / cm 3 ): 1ml;

[0034] Isopropanol (analytical pure): 84ml;

[0035] Glass fiber silk material: 0.45g (weight ratio 4%), wherein the diameter of glass fiber silk material is 0.1mm, and length is 4mm,

[0036] First weigh acetylene black for use, then measure polytetrafluoroethylene emulsion and isopropanol respectively, mix them evenly, add them to acetylene black, stir evenly, weigh glass fiber filaments and add them to the mixture, mix evenly to get positive electrode paste thing;

[0037] 2) Molding:

[0038] Put the uniformly mixed positive electrode paste into the extruder, and squeeze out the po...

Embodiment 2

[0050] Positive electrode formula:

[0051] Acetylene black (battery grade): 10g;

[0052] PTFE emulsion (60% water emulsion, density 1.5g / cm 3 ): 1ml;

[0053] Isopropanol (analytical pure): 84ml;

[0054] Glass fiber filament material: 1.16g (9.6% by weight), wherein the glass fiber filament material has a diameter of 0.15mm and a length of 3mm.

[0055] Fabrication of ER34615 experimental high-temperature lithium thionyl chloride battery.

[0056] The high-temperature ER34615 experimental battery is discharged at a constant current of 30mA to 2.0V at a temperature of 175±2°C, and the discharge capacity is 12.37Ah.

[0057] Others are all the same as in Example 1.

Embodiment 3

[0059] Positive electrode formula:

[0060] Acetylene black (battery grade): 10g;

[0061] PTFE emulsion (60% water emulsion, density 1.5g / cm 3 ): 1ml;

[0062] Isopropanol (analytical pure): 84ml;

[0063] Glass fiber filament material: 1.42g (11.5% by weight), wherein the glass fiber filament material has a diameter of 1mm and a length of 6mm.

[0064] Fabrication of ER251000 experimental high-temperature lithium thionyl chloride battery.

[0065] The high-temperature ER251000 experimental battery is discharged at a constant current of 50mA to 2.0V at a temperature of 175±2°C, and the discharge capacity is 8.56Ah.

[0066] Others are all the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com