Oil tray for a combustion engine

A technology of oil collecting device and internal combustion engine, which is applied to the device for keeping the lubricant liquid level constant, the lubrication of the engine, the oil pan, etc., which can solve the problems of troublesome installation and complicated structure, and achieve simple structure, simple installation and low cost. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

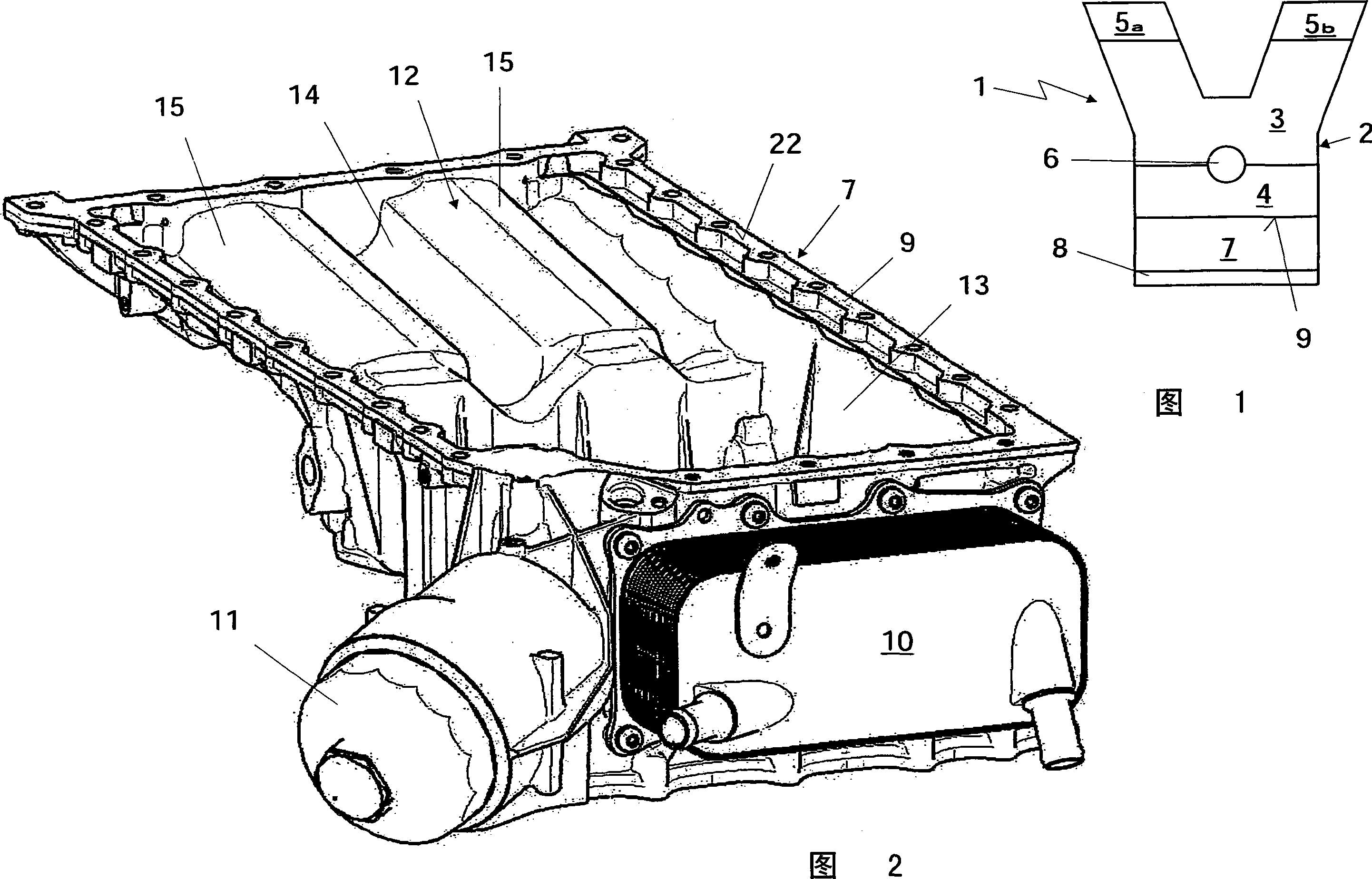

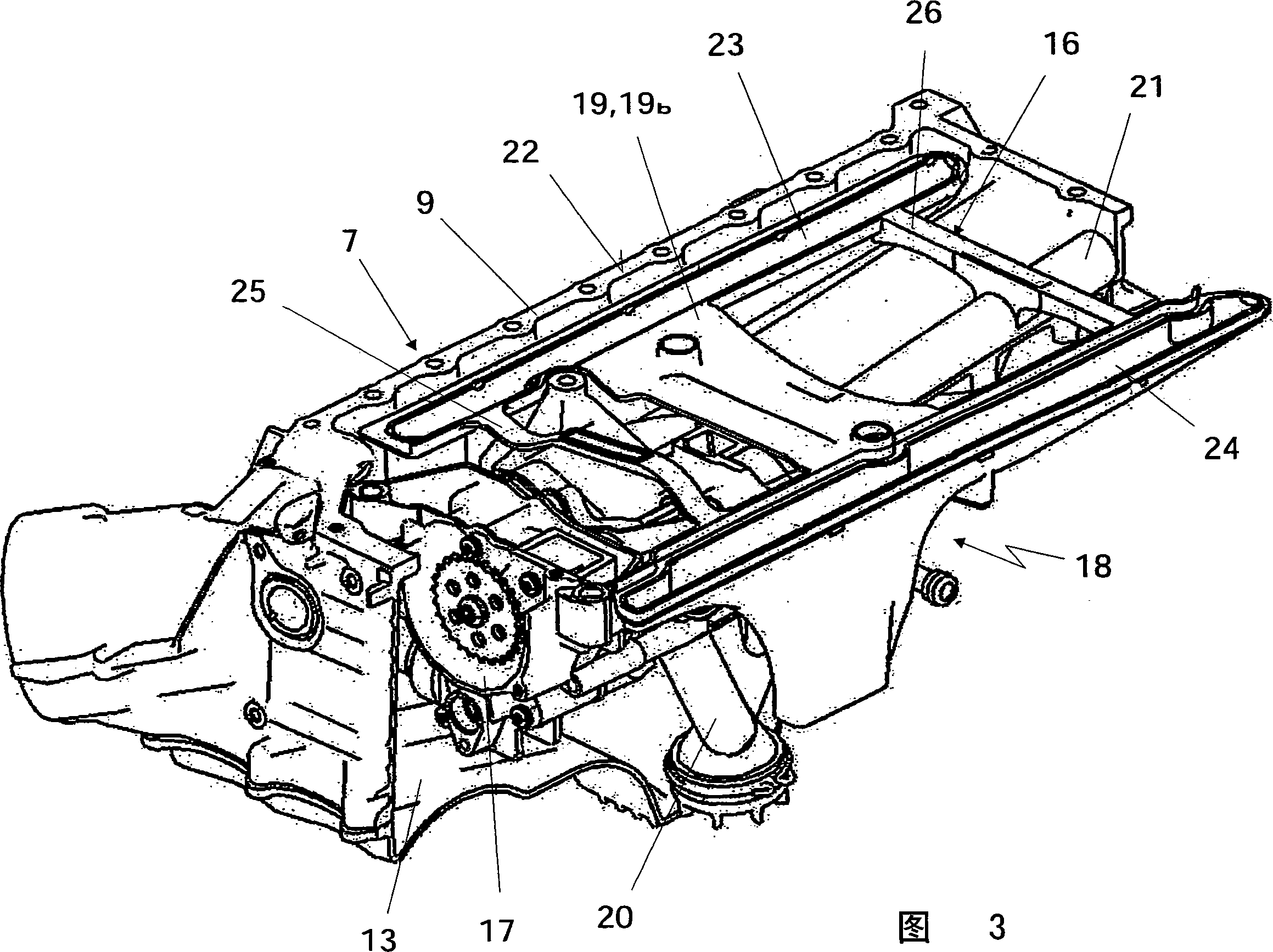

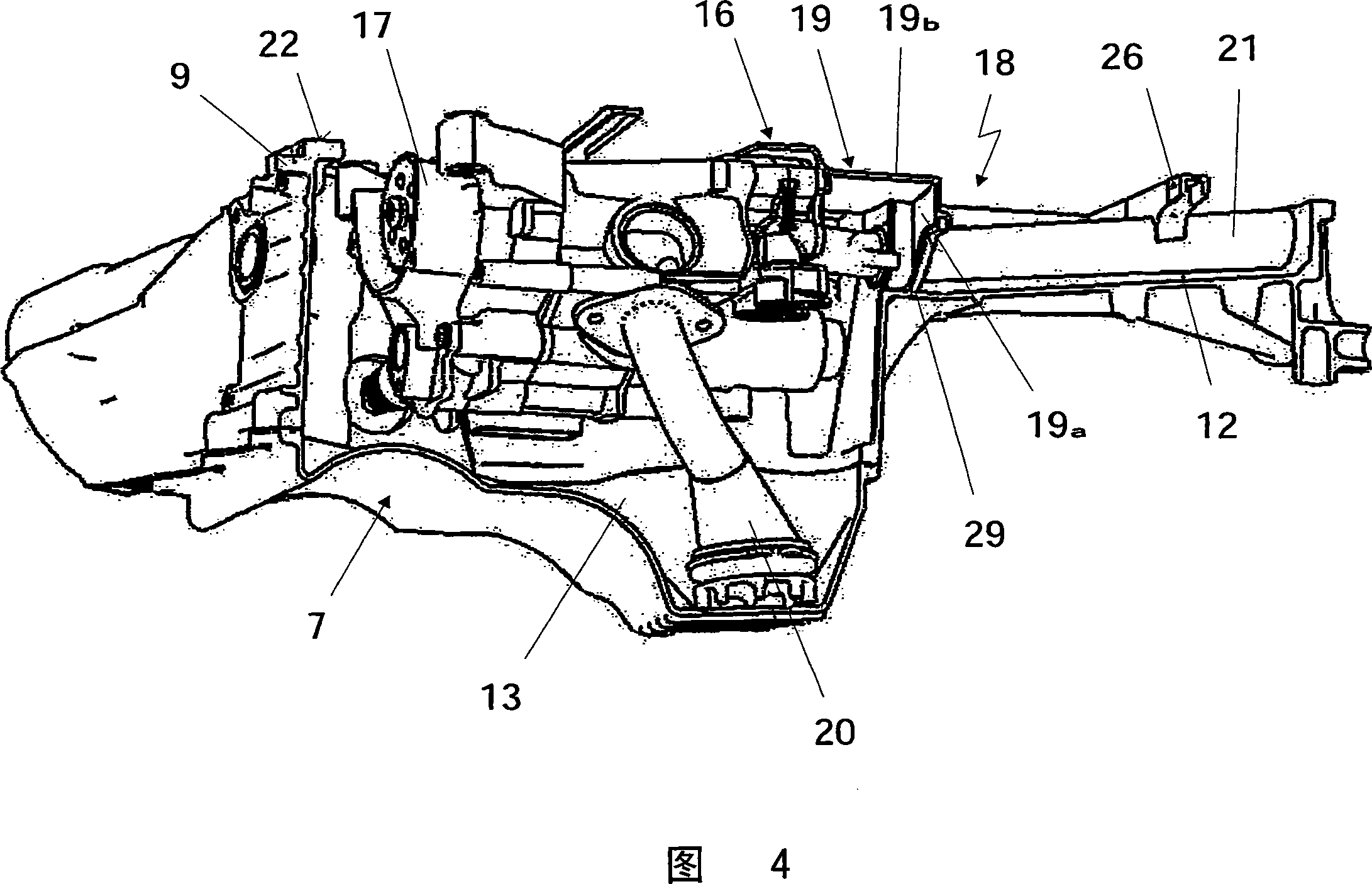

[0019] FIG. 1 is a schematic illustration of an internal combustion engine 1 with a crankcase 2 . The crankcase has a crankcase upper part 3 and a crankcase lower part 4 , also called bedplate. Two cylinder heads 5 a and 5 b are arranged on the crankcase 2 , which in this case is designed in a V-shaped configuration. The two cylinder heads can be designed in a design known per se. A crankshaft 6 is also rotatably mounted between the upper crankcase part 3 and the lower crankcase part 4 in a manner known per se. In addition, an oil collection tank 7 connected to the lower part 4 of the crankcase is also provided at the lower part of the crankcase 2 . The oil collecting tank is also designed in a manner known per se to hold lubricating oil for the internal combustion engine and is closed downwards by an oil sump 8 . The oil sump 8 can be made of sheet metal, for example in the form of a cover, and is necessary because the oil collecting tank 7 is in this case a die-cast part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com