Sintering machine wind box end sealing apparatus

A technology of end sealing and sintering machine, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc. It can solve the bad influence of the sealing effect of the end sealing device of the sintering machine bellows, the top sealing plate cannot be reset in time, and the sealing effect is affected, etc. problems, achieve the effects of preventing jamming, simplifying the structure, and improving the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

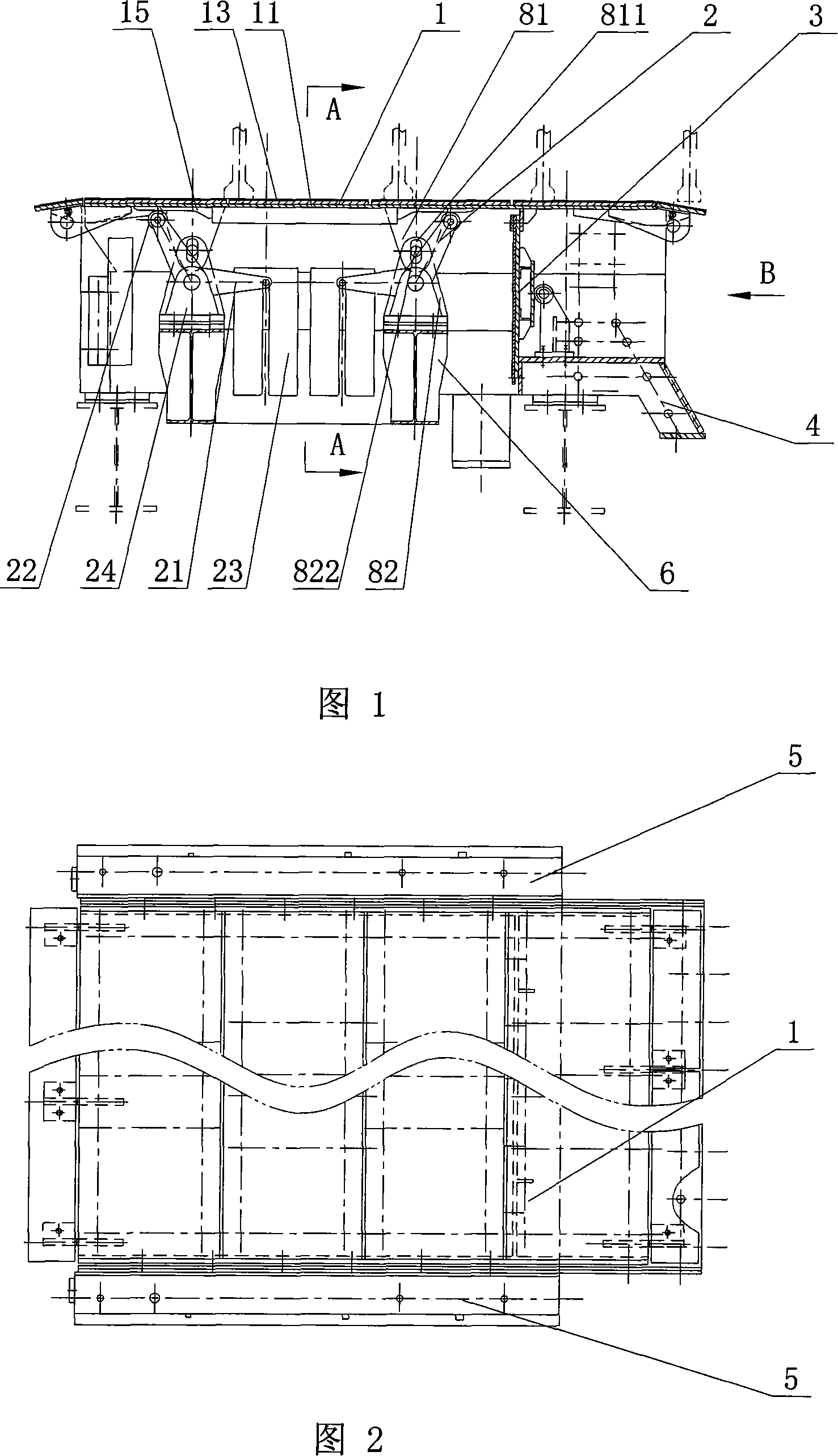

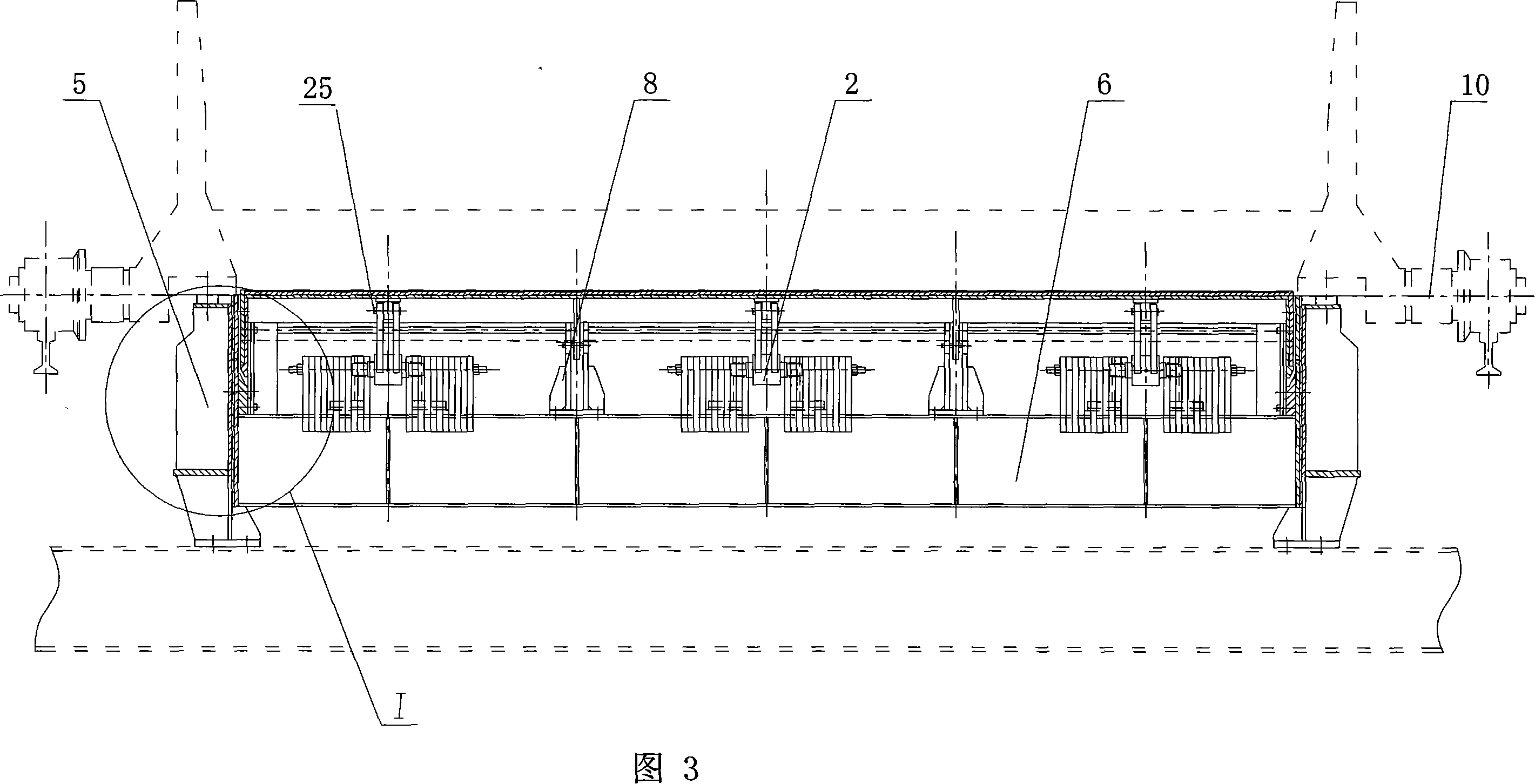

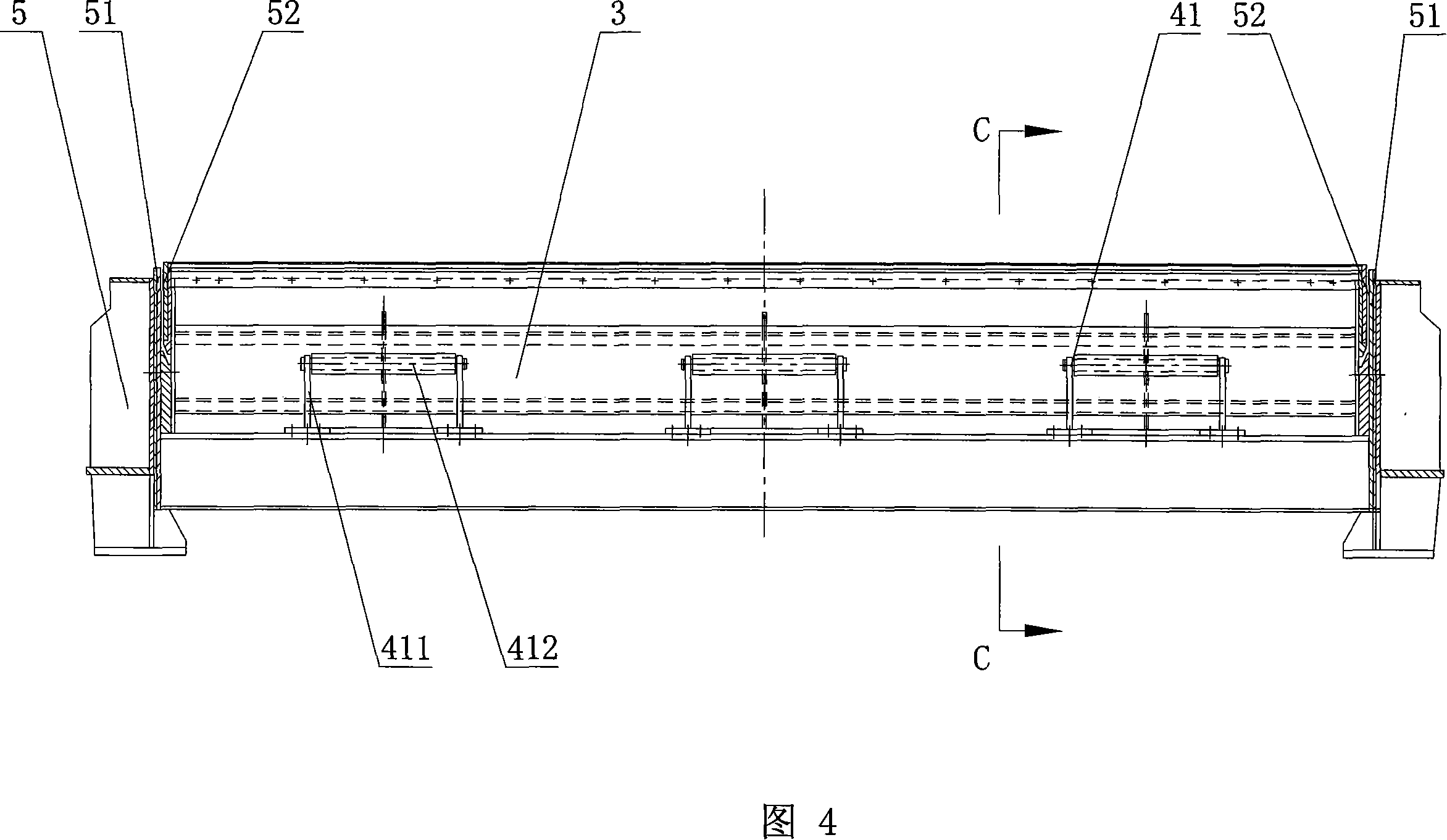

[0042]As shown in Figures 1 to 7, the end sealing device of the sintering machine bellows of the present invention includes a top sealing plate 1, a connecting rod mechanism 2, an end sealing plate 3, a beam frame 4, two side beams 5 and two supporting beams 6 , the two ends of the crossbeam frame 4 and each support beam 6 are respectively connected to the two side beams 5, the crossbeam frame 4 is located in the bellows area, the two support beams 6 are located in the atmospheric pressure area, and each support beam 6 is fixedly equipped with three sets of linkage mechanisms 2, the top The sealing plate 1 is connected above the connecting rod mechanism 2, the upper part of the end sealing plate 3 is connected with the top sealing plate 1, and the lower part is in contact with the beam frame 4, and the top sealing plate 1 is a groove that is set on the inner side of the beams 5 on both sides and opens downward. body, the tank body is composed of elastic whole plate 11 and side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com