System and technique for transporting rail heterotype considerable tank truck

A quasi-rail special-shaped, large-capacity technology, applied in the direction of manufacturing tools, casting workshops, metal processing equipment, etc., can solve the problems of low production efficiency, high operating costs, poor three-off effect, etc., to avoid molten iron backflow operations, solve graphite Flying dust pollution, good effect on environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

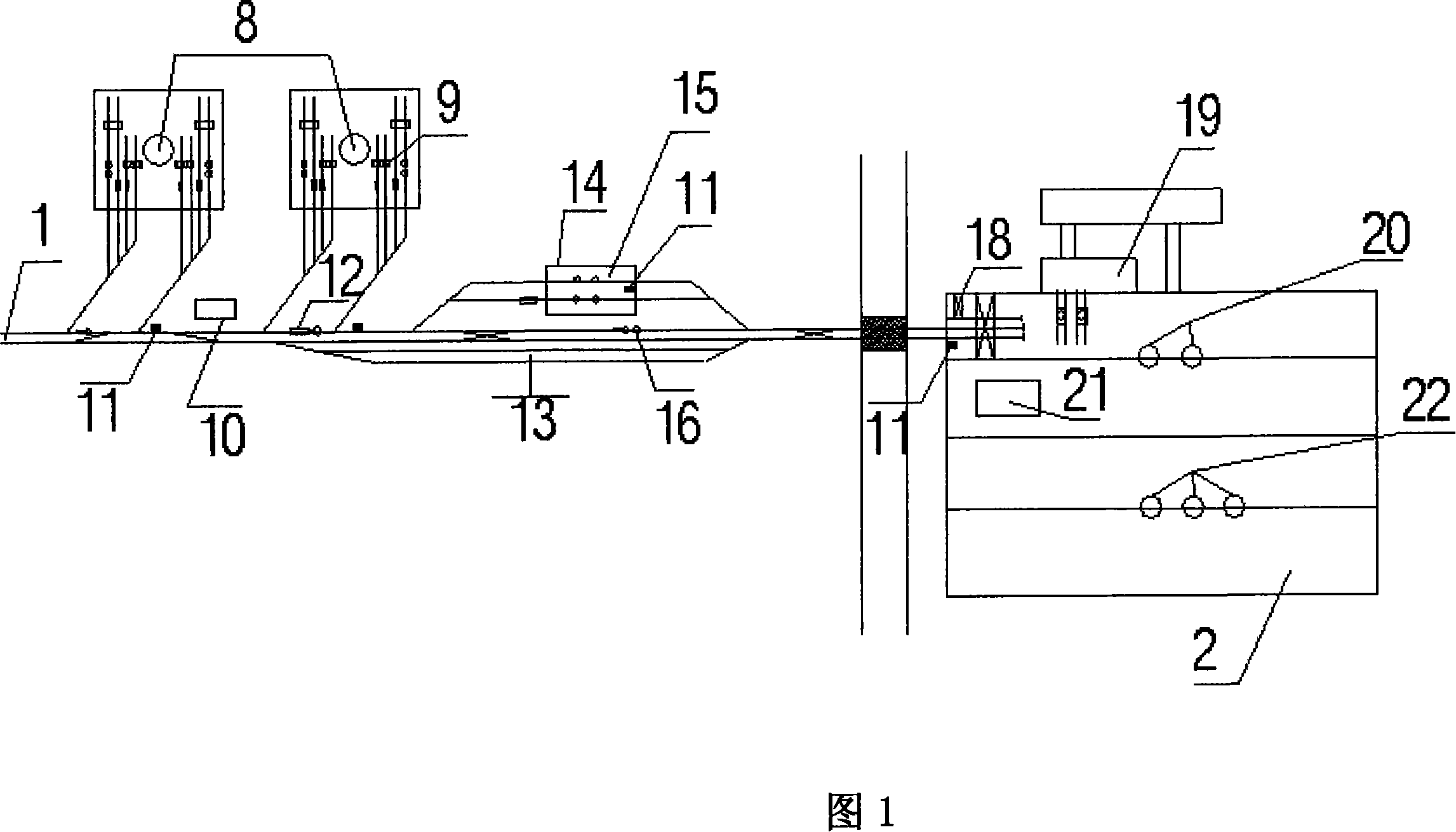

[0031] As shown in Figure 1,

[0032] 1. The molten iron transportation line 1 enters the steelmaking workshop 2 in parallel and straight lines

[0033] After analyzing the way of molten iron transportation line 1 entering steelmaking workshop 2, the way of molten iron transportation line 1 vertically entering steelmaking workshop 2 requires locomotive picking and hanging operations, which is not conducive to steelmaking production organization and transportation, and the transportation operation is unsafe, so It is determined that the short interface technology must adopt the method that the molten iron transportation line 1 enters the steelmaking workshop 2 in a parallel and straight line.

[0034] 2. The blast furnace 8 is arranged next to the steelmaking workshop 2

[0035] The short interface technology requires that the molten iron transportation line is straight and short, so as to ensure the safe and reliable operation of the molten iron tank, accelerate the turnover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com