Cooler

A cooling machine and cooled technology, which is applied in the direction of processing discharged materials, furnaces, direct contact heat exchangers, etc., can solve the problems of troublesome installation and maintenance, high cost of coolers, complex structure, etc., and achieve easy installation and maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

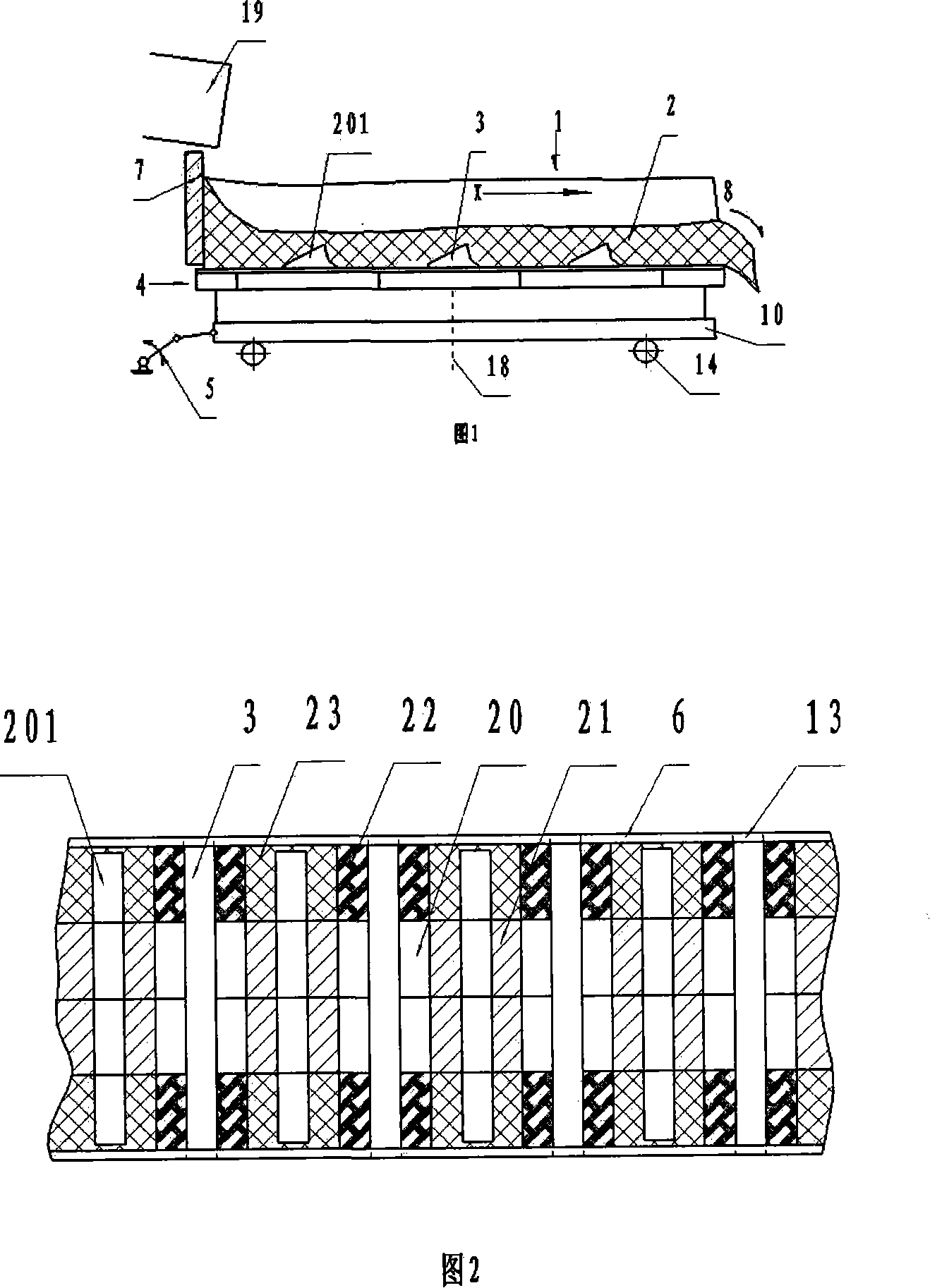

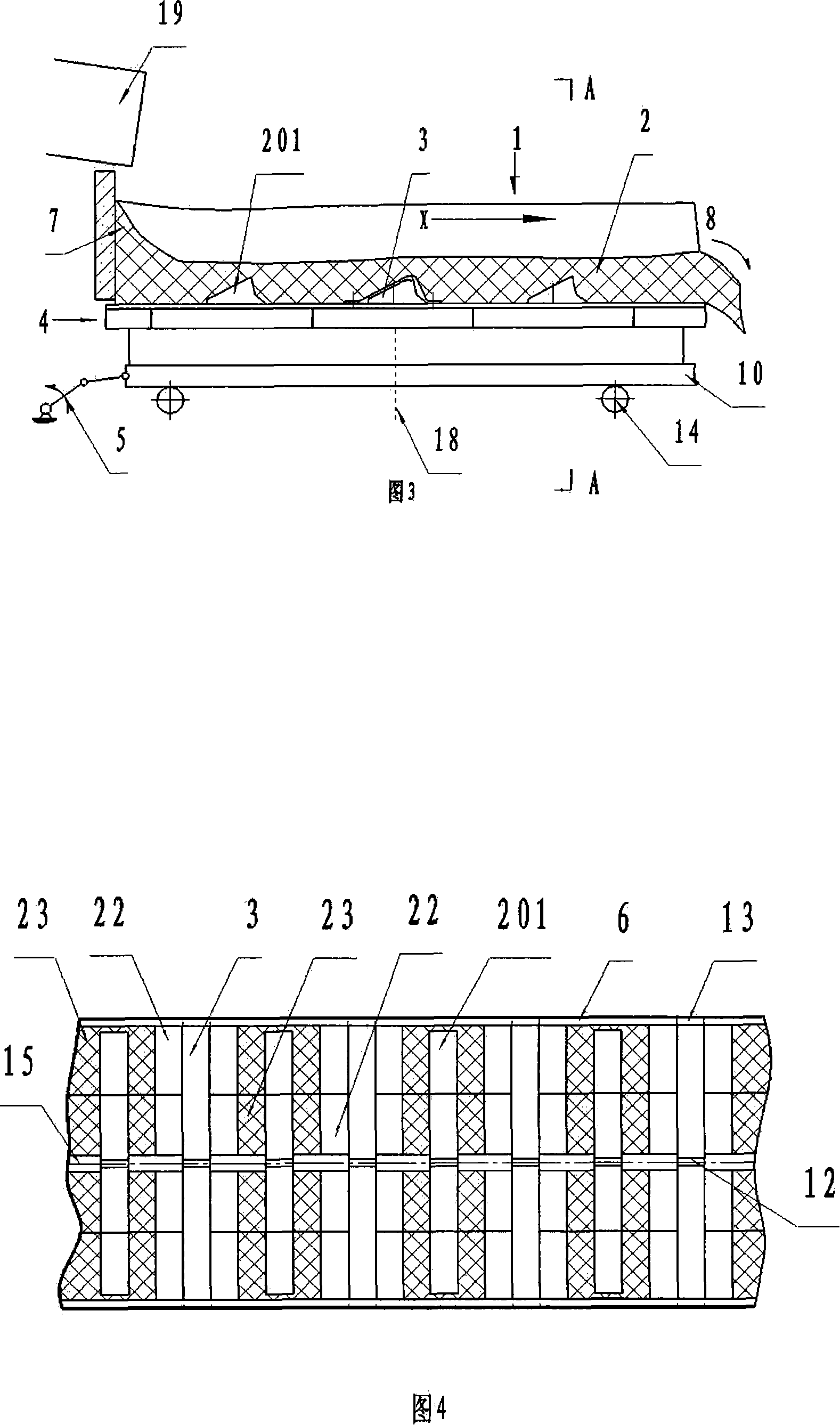

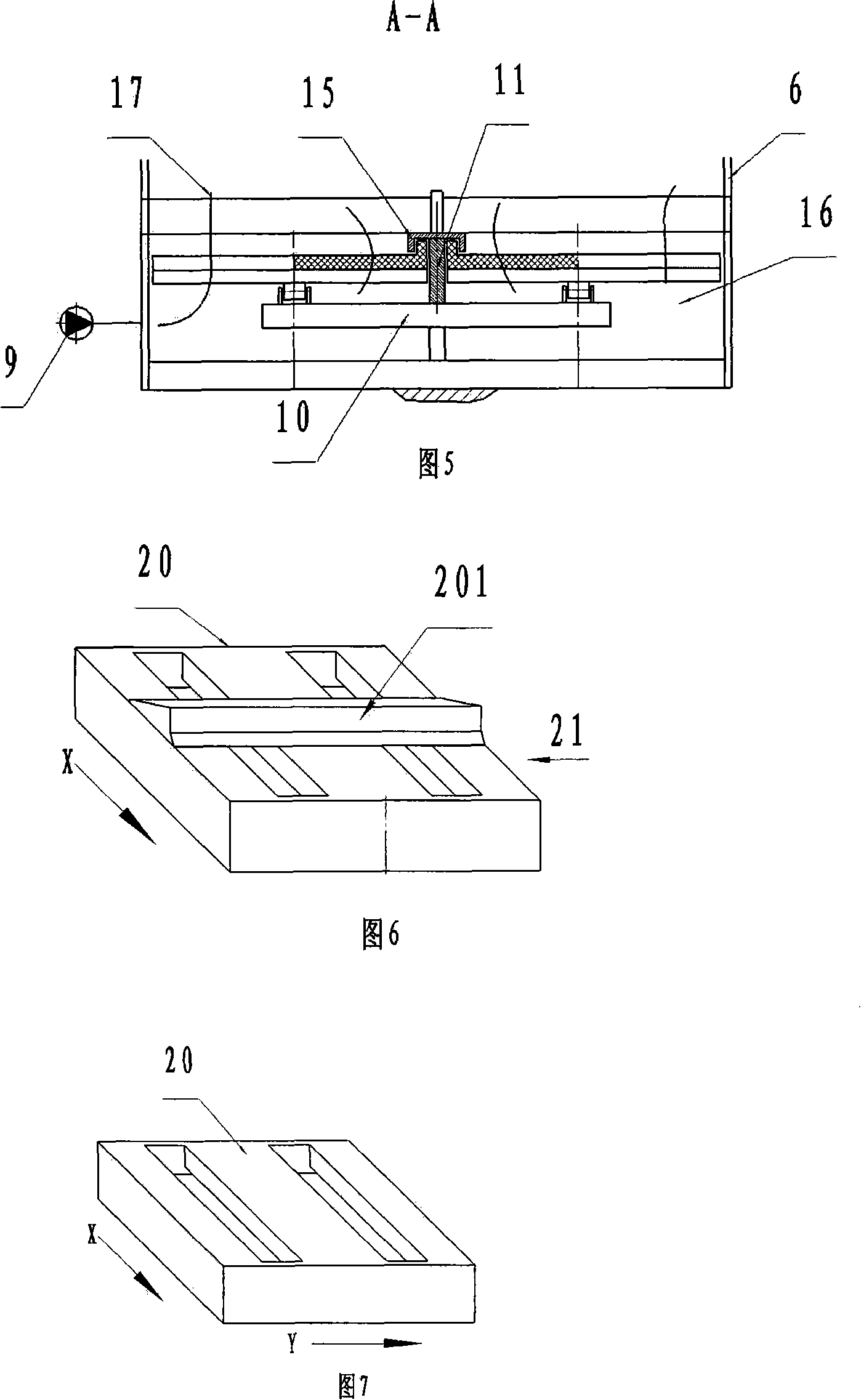

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

[0030] See Fig. 1, the cooler 1 in Fig. 1 is made up of feed end 7, discharge end 8, grate bed 4, traditional grate plate 20 (see Fig. 2 and 4), driving device 5, side wall 6 (see Fig. 2, 4 and 16), the wind chamber 16 (seeing Fig. 5) that provides cold wind 17 by wind source 9 is made up of, and the material 2 that is cooled is arranged on the grate bed 4, and material 2 can be the high-temperature material discharged from industrial kiln 19, and material 2 It can be granular or powdery, or a mixture of the two. In Fig. 1, what constitute the grate bed 4 are the convex-edged grate plate 21 and the traditional grate plate 20 arranged in sequence, as shown in Fig. 2, wherein the convex-edged grate plate 21 and the side wall 6 are in contact with the convex-edged grate plate 23 The traditional grate plate 20 is in contact with the side wall 6 as the traditional side gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com