Crankshaft dynamic balance design method

A design method and crankshaft technology, applied in calculation, special data processing applications, instruments, etc., can solve problems such as large funds, low dynamic balance calculation accuracy, and long design and development time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

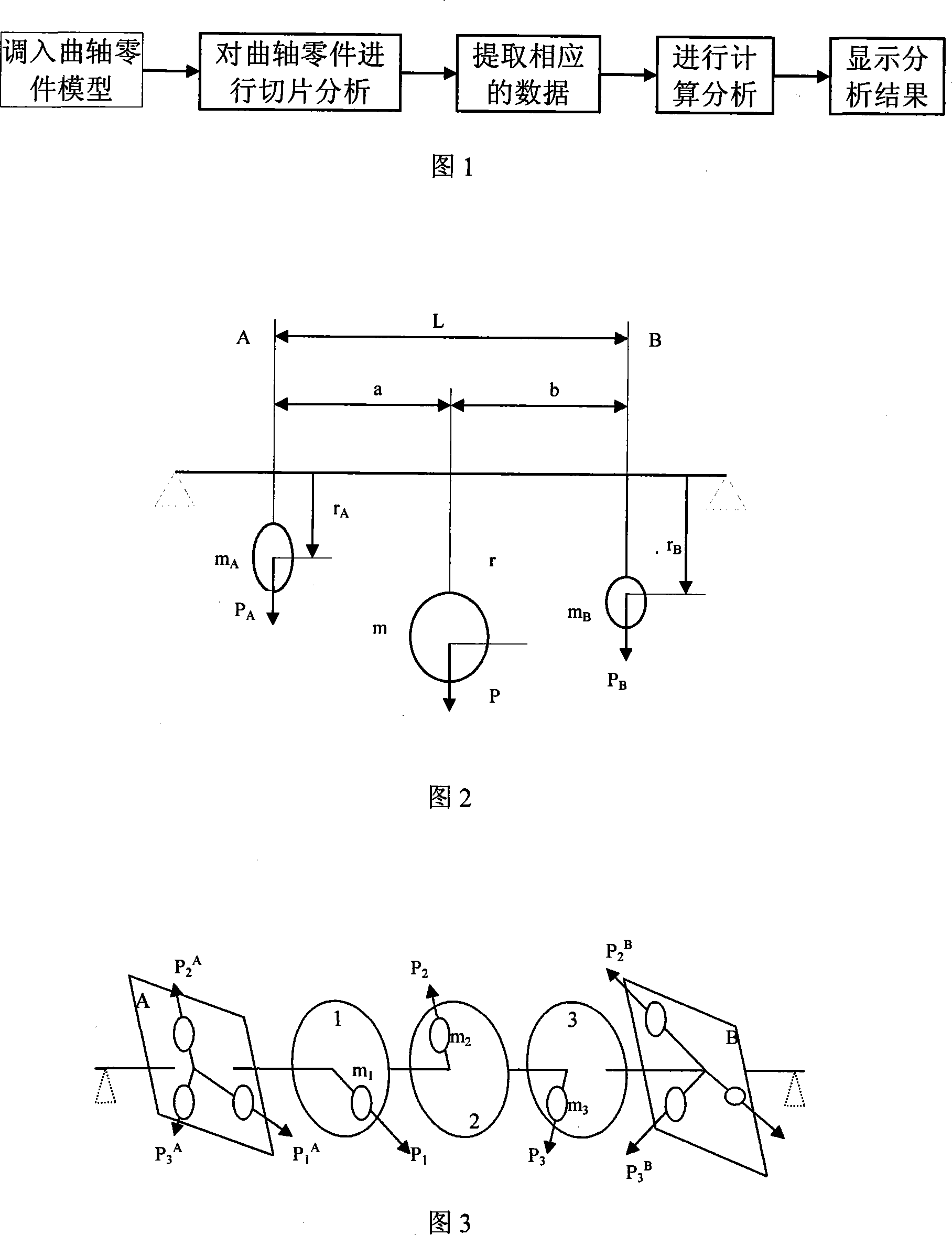

[0039]A design method for crankshaft dynamic balance. The model of the crankshaft part is sliced and analyzed, that is, the model of the crankshaft part is segmented axially for a limited number of times. Finally, compare the obtained corresponding data with the preset data, and finally judge whether the dynamic balance of the obtained crankshaft part model is within the range of production requirements.

[0040] The corresponding data includes quality and radial direction.

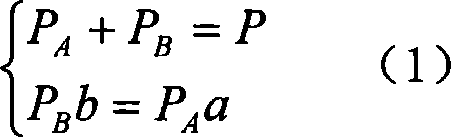

[0041] The slice analysis step is based on the principle of rigid rotor dynamic balance analysis to set two balance correction surfaces and reference datum planes. The analysis steps are as follows:

[0042] A. First, select two balance correction surfaces as the reference for dynamic balance calculation. After one balance correction surface, select another balance correction surface by rotating or moving parts;

[0043] B. The user then selects an end face of the crankshaft part as the reference datum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com