Underground catalytic gasification process of coal

A technology of catalysts and catalyst particles, applied in coal gasification, underground mining, construction, etc., can solve the problems that technical means cannot be applied to underground coal gasification, and achieve the effect of catalytic gasification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

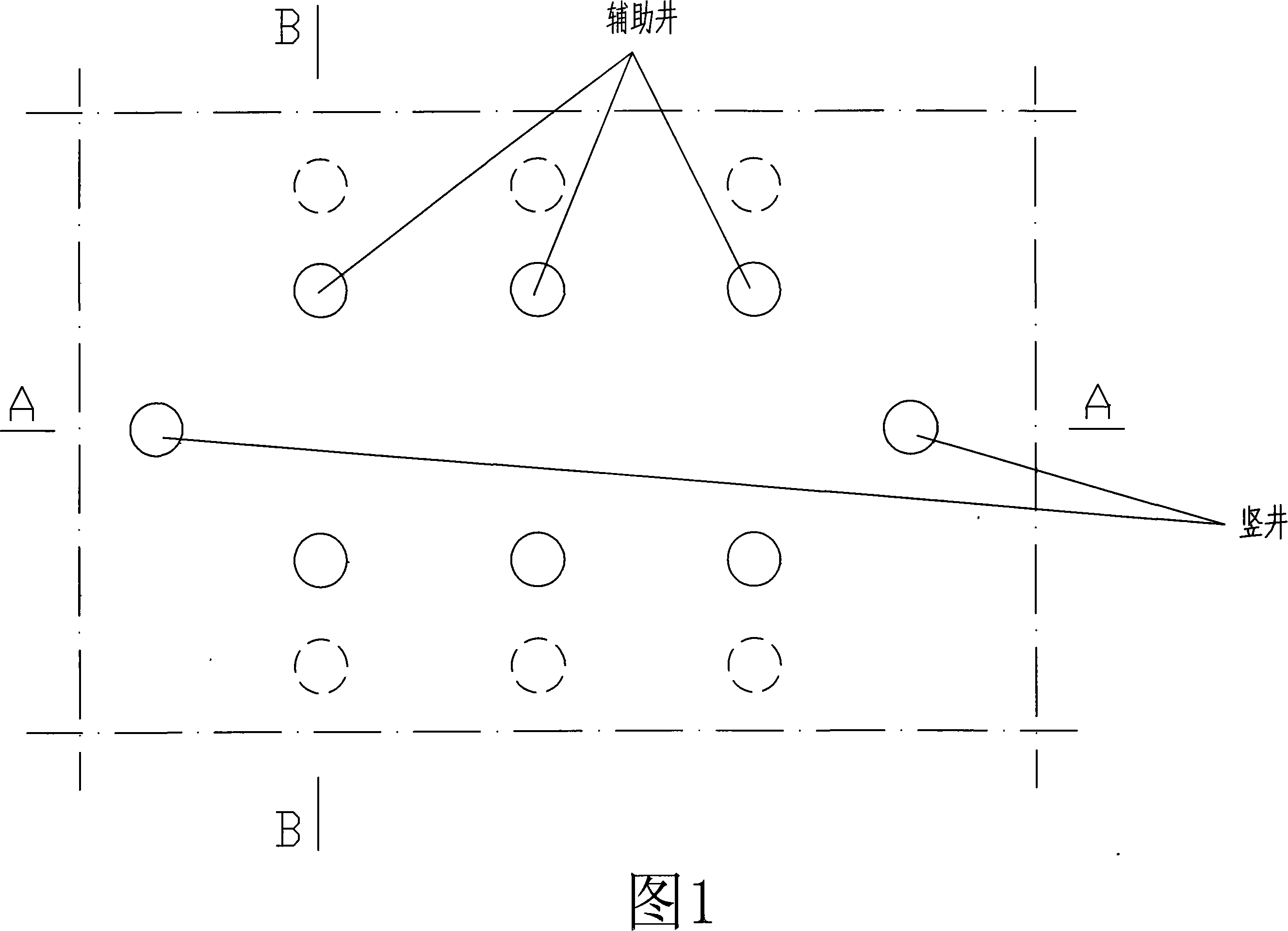

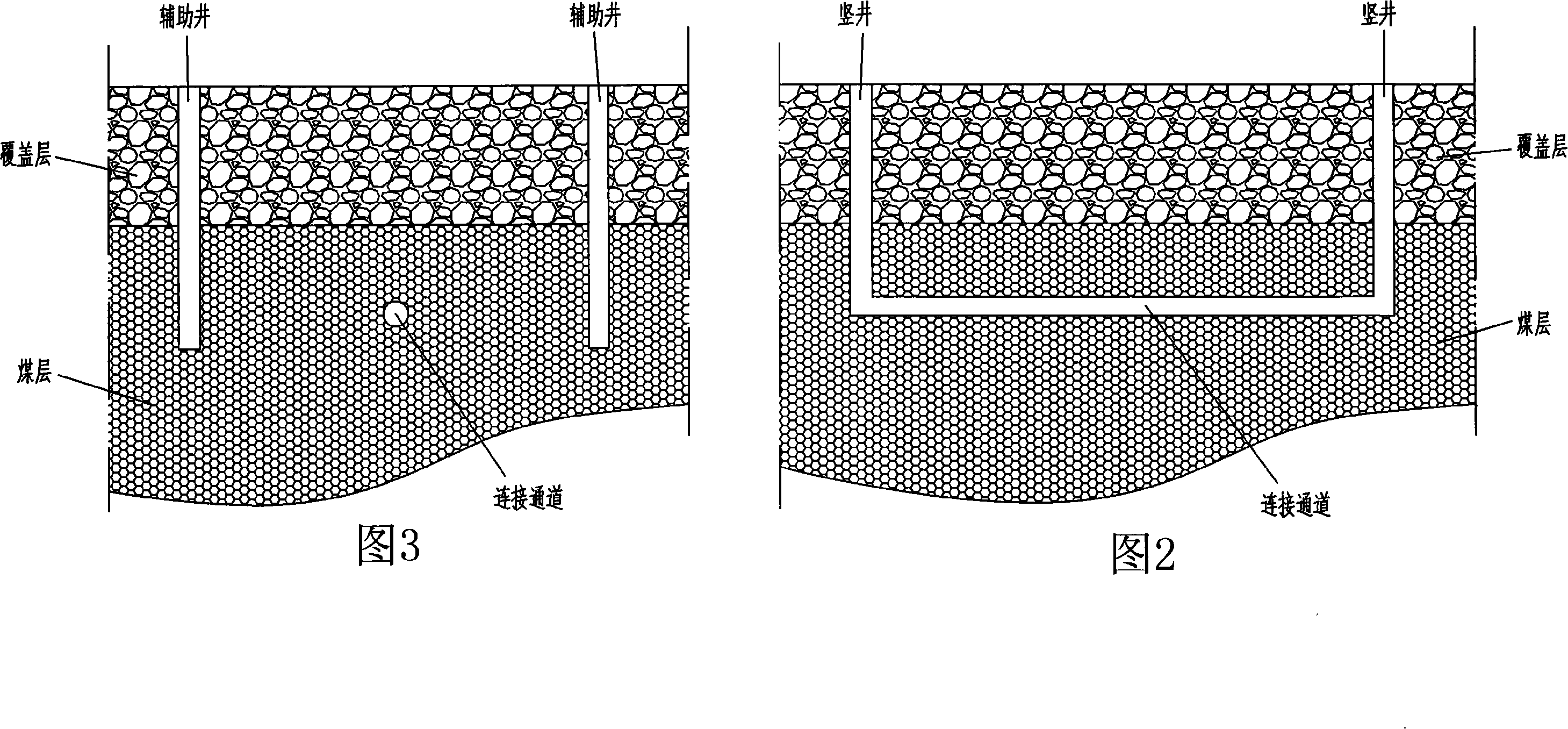

[0022] As shown in accompanying drawings 1-3, when the underground catalytic gasification process of a kind of coal of the present invention is carried out, firstly, No. 1 and No. 2 shafts are drilled at intervals on the ground, and the shafts are drilled to the bottom of the underground coal seam, and then Open the two vertical shafts No. 1 and No. 2 along the coal seam to form a connecting channel connecting the two vertical shafts; then drill a number of auxiliary wells along the extending direction of the connecting channel on both sides of the connecting channel, and the auxiliary wells are also drilled from the ground to the coal seam; Inject high-pressure water or high-pressure gas into No. 1 and No. 2 shafts under open conditions, and add pre-prepared catalyst particles to high-pressure water or high-pressure gas. Since there is a pressure difference between the connecting channel and the auxiliary wells on both sides, the injection The high-pressure water or high-press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com