Combined type fuel tank with three tanks

A combined, fuel tank technology, applied in the layout combined with the fuel supply of the internal combustion engine, the electronic control of the exhaust gas treatment device, the exhaust gas treatment, etc., can solve the problem of no patent application, etc., to solve the installation and layout problems, and facilitate maintenance. , the effect of beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

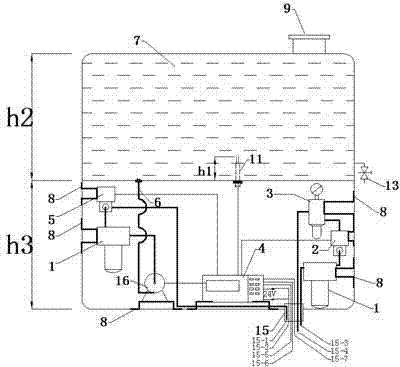

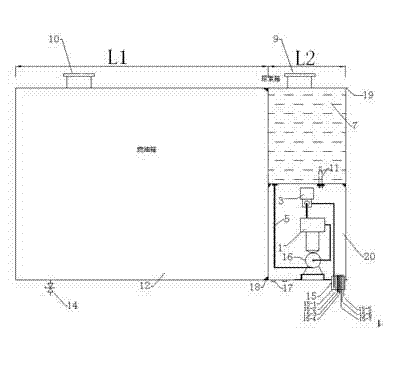

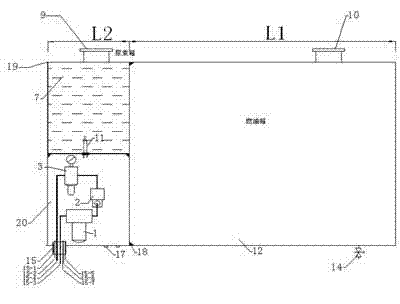

Embodiment 1

[0030] The selected material is SUS304 or SUS441 stainless steel plate, its thickness is 1.2mm, the volume capacity relation L1 / L2=5 of fuel tank body 12 and reductant tank body 7; It is made of holes, rolled plates, and welded. After being installed on the car, it can be seen that the fuel tank 12 is arranged on the car at the farthest distance from the engine, while the urea reducing agent box 7 and the electrical control box 20 are arranged on the car. The position is the closest to the engine, and the combined fuel tank is fixed on the vehicle frame with a bracket; the urea reducing agent tank cover 9 and the fuel tank cover 10 are facing the outside of the compartment; wherein, the fuel tank body 12 and the urea reducing agent tank body 7 Complete the 30min pressure seal test under the constant pressure of 0.08Mpa; the ratio of the height h1 of the urea reducing agent liquid level sensor 11 to the height h2 of the reducing agent tank 7 is h1 / h2=1 / 5; the urea reducing agent...

Embodiment 2

[0032] The selected material is SUS304 or SUS441 stainless steel plate, its thickness is 1.4mm, the volume capacity relationship L1 / L2=10 between fuel tank body 12 and reductant tank body 7; Holes, rolled plates, and welding are made into fuel tank 12, urea reducing agent box 7 and electrical control box 20 respectively. After the combined fuel tank is installed on the vehicle, the fuel tank 12 is arranged on the vehicle. It is the farthest from the engine, and the position on the vehicle where the urea reducing agent box 7 and the electrical control box 20 are arranged is the closest to the engine. The combined fuel tank is fixed on the vehicle frame with a bracket; the urea reducing agent box The cover 9 and the fuel tank cover 10 are facing the outside of the compartment; at the same time, the full scale fuel and urea reducing agent are filled, the consumption rate of the urea reducing agent is 1 / 20~1 / 25 of the fuel, and the amount of the two liquids can be maintained almost...

Embodiment 3

[0034] The selected material is SUS304 or SUS441 stainless steel plate, its thickness is 1.4mm, the volume capacity relation L1 / L2=15 of fuel tank body 12 and reductant tank body 7; Holes, rolled plates, and welding are made into fuel tank 12, urea reducing agent box 7 and electrical control box 20 respectively. After the combined fuel tank is installed on the vehicle, the fuel tank 12 is arranged on the vehicle. It is the farthest from the engine, and the position on the vehicle where the urea reducing agent box 7 and the electrical control box 20 are arranged is the closest to the engine. The combined fuel tank is fixed on the vehicle frame with a bracket; the urea reducing agent box The cover 9 and the fuel tank cover 10 face the outside of the compartment; among them, the fuel tank 12 and the urea reducing agent tank 7 have completed a 30-min pressurization and sealing test at a constant pressure of 0.08Mpa; the height h1 of the urea reducing agent liquid level sensor 11 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com