Setting device, component mounting system, program and calculating method

A technology for setting devices and installing components, applied in computing, electrical components, electrical components, etc., can solve the problem of longer component installation time, and achieve the effect of shortening the installation time and reducing the amount of movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

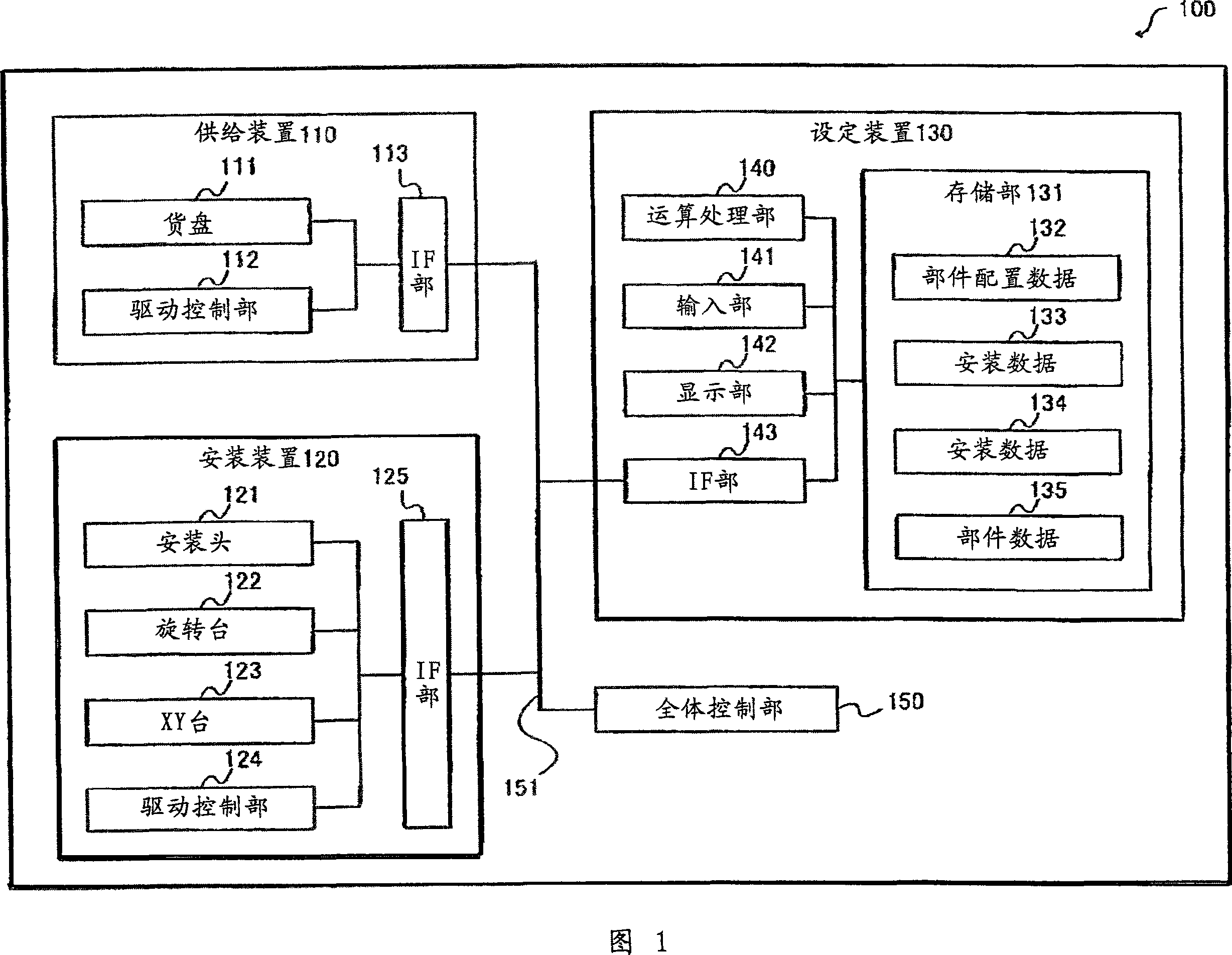

[0025] Fig. 1 is a schematic diagram of a component mounting system 100 according to a first embodiment of the present invention.

[0026] As shown in the figure, the component mounting system 100 has a supply device 110 , a mounting device 120 , a setting device 130 , and an overall control unit 150 , and these are connected to each other via a bus 151 .

[0027] The supply device 110 has a pallet 111 , a drive control unit 112 , and an IF unit 113 .

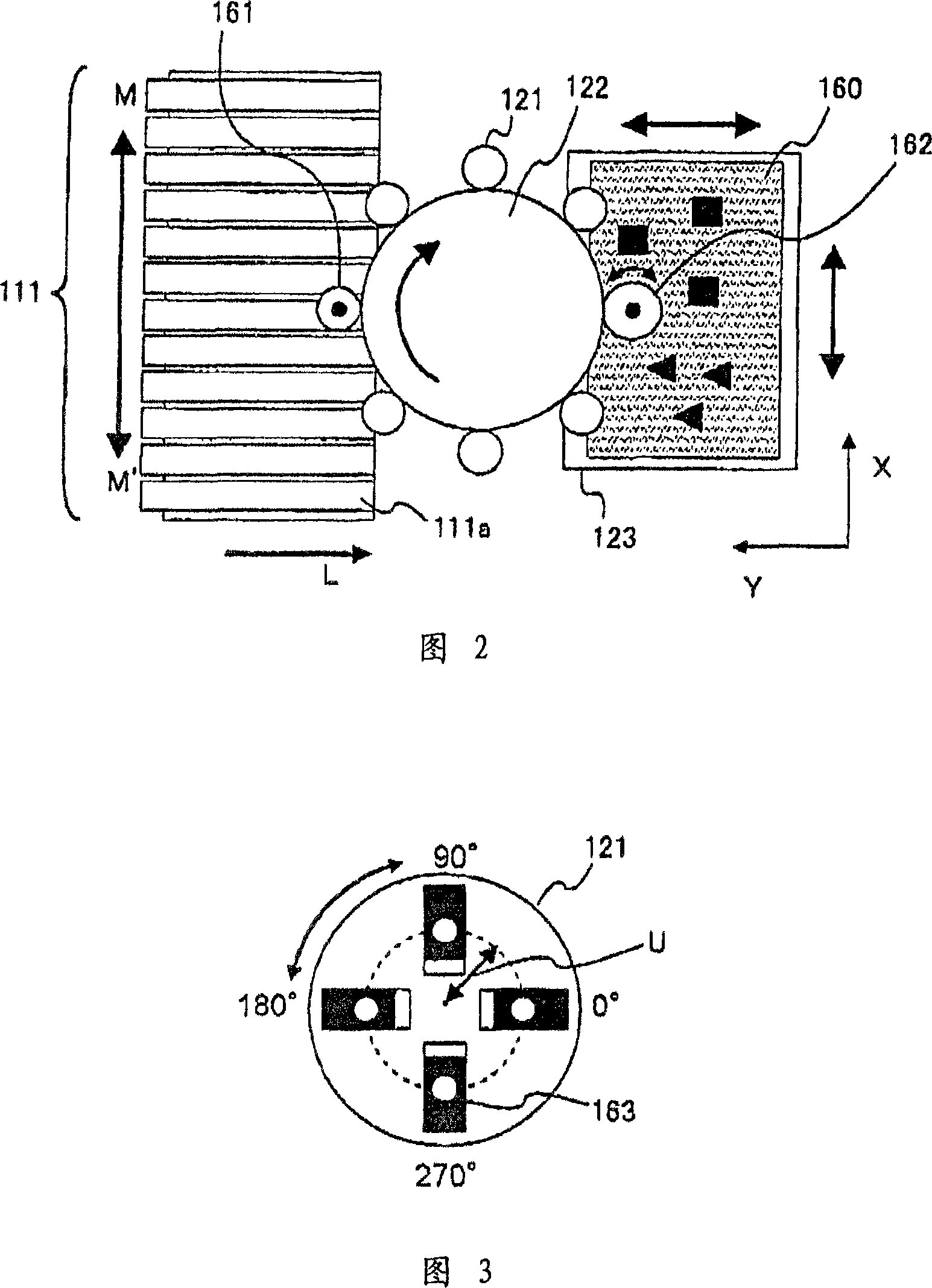

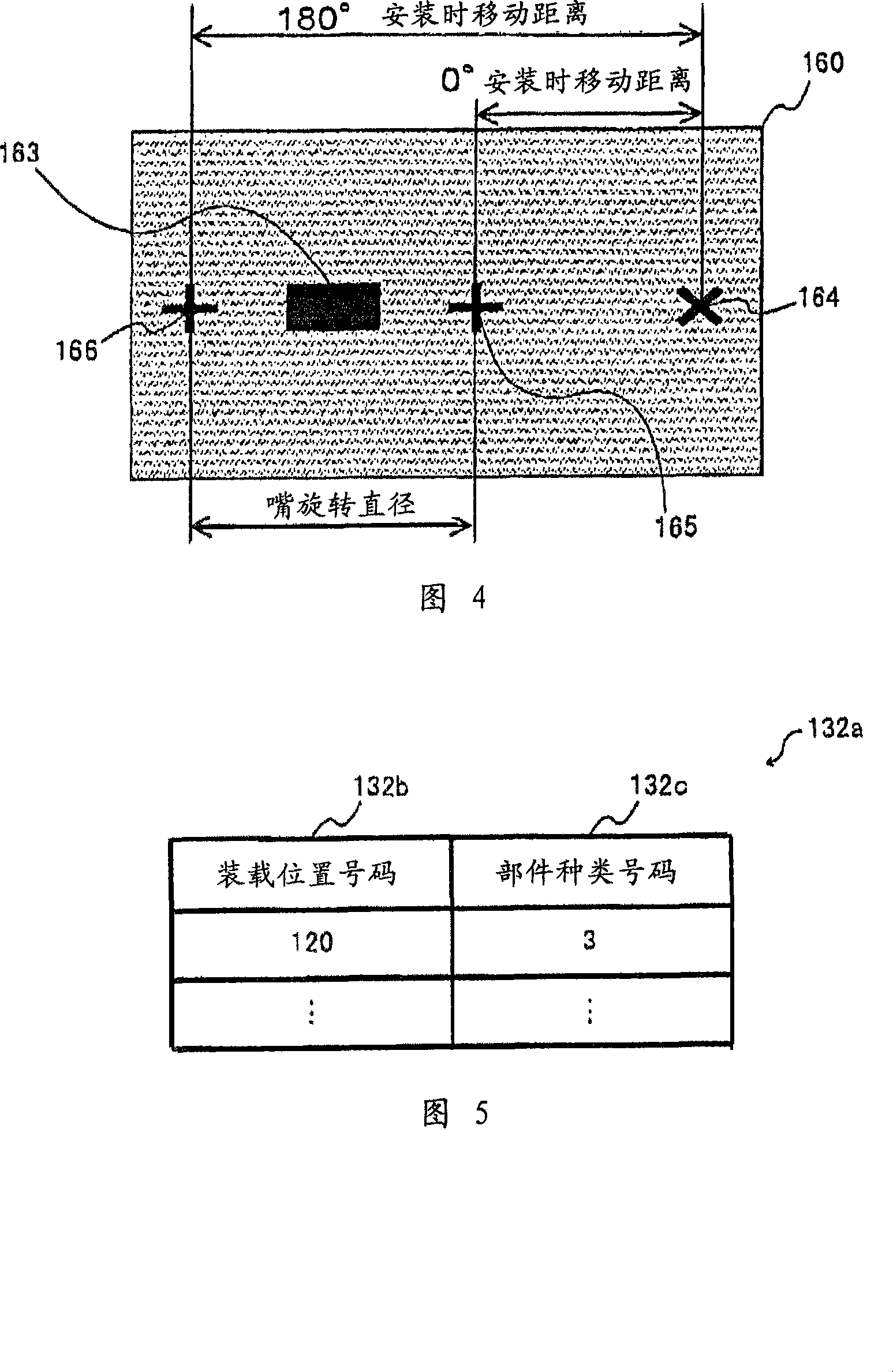

[0028] Pallet 111, as shown in FIG. 2 (top view of pallet 111, mounting head 121, rotary table 122, and XY table 123), holds components to be mounted on base plate 160 on a feeder belt, and a plurality of configurations are transported to after use. The tape feeder 111a is attached to the position where the mounting head 121 is sucked.

[0029] In addition, one kind of parts is respectively held in the same posture on one tape feeder 111a by placing the pallet 111 in a direction (M direction or M' direction) perpendicular to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com