Method of manufacturing an engraved plate

A laser engraving machine, mastering technology, used in manufacturing tools, printing plates, printing plate preparation, etc., can solve the problem of not providing accurate control of engraving depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

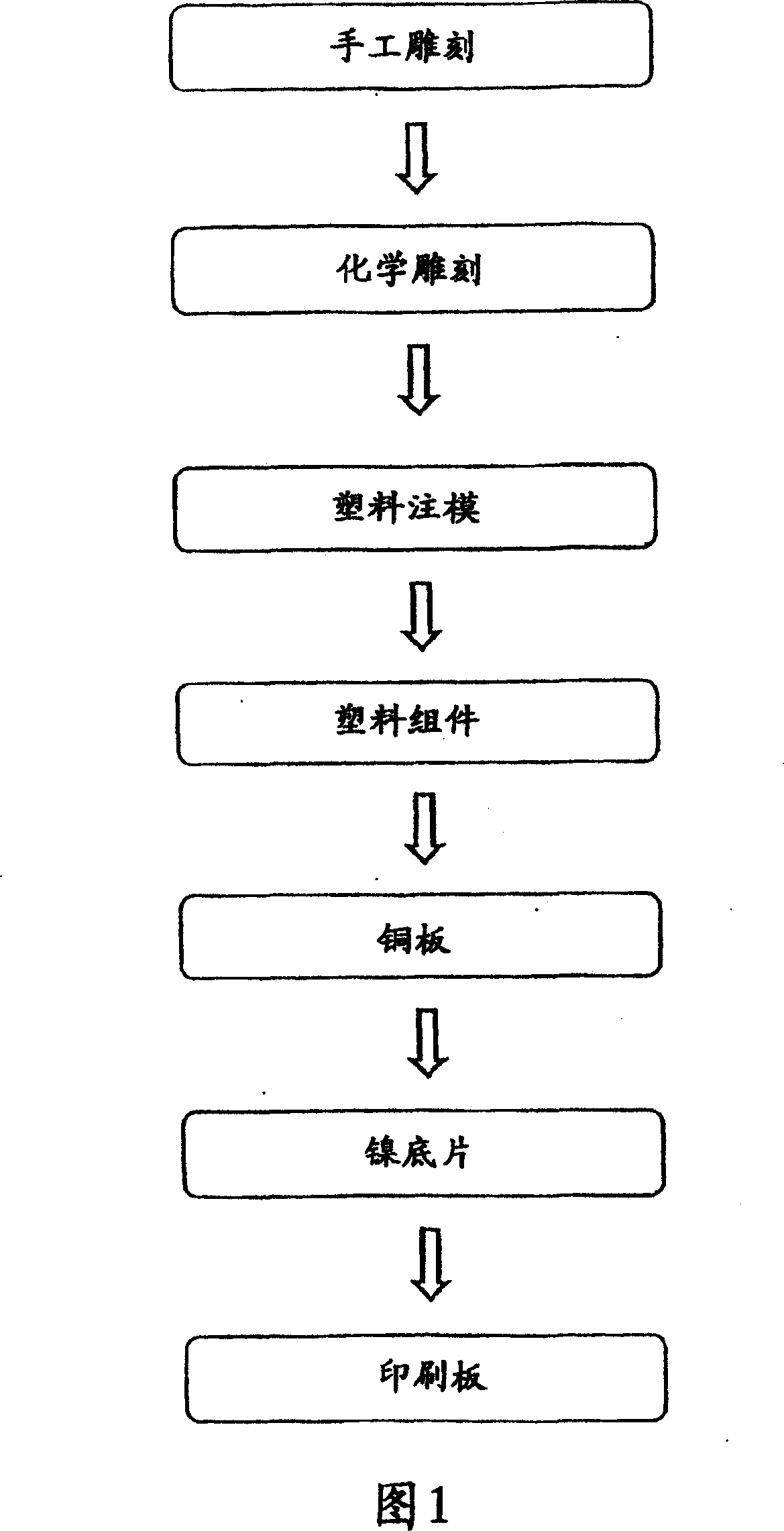

[0040] Figure 1 schematically shows the state of the technical process traditionally used by a security printing factory for the manufacture of gravure printing plates.

[0041] The first step is to hand carve an image with depth, such as a portrait, in a steel or copper mold. This step required months of labor by a skilled sculptor.

[0042] The second step is to create a copy of this hand-engraved mold and add other lines to the mold by chemical etching. These lines may be computer-generated secret patterns that are printed during the gravure process.

[0043] The third step is to form a plastic imprint of the mold. It will be possible to make as many impressions as the security document printed on each page.

[0044] The fourth step is to cut these stamps into shape.

[0045] The fifth step is to place the cut stamps into rows and columns and then weld them together to create a multi-image plastic assembly.

[0046] The sixth step is to silver the multi-image plastic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com