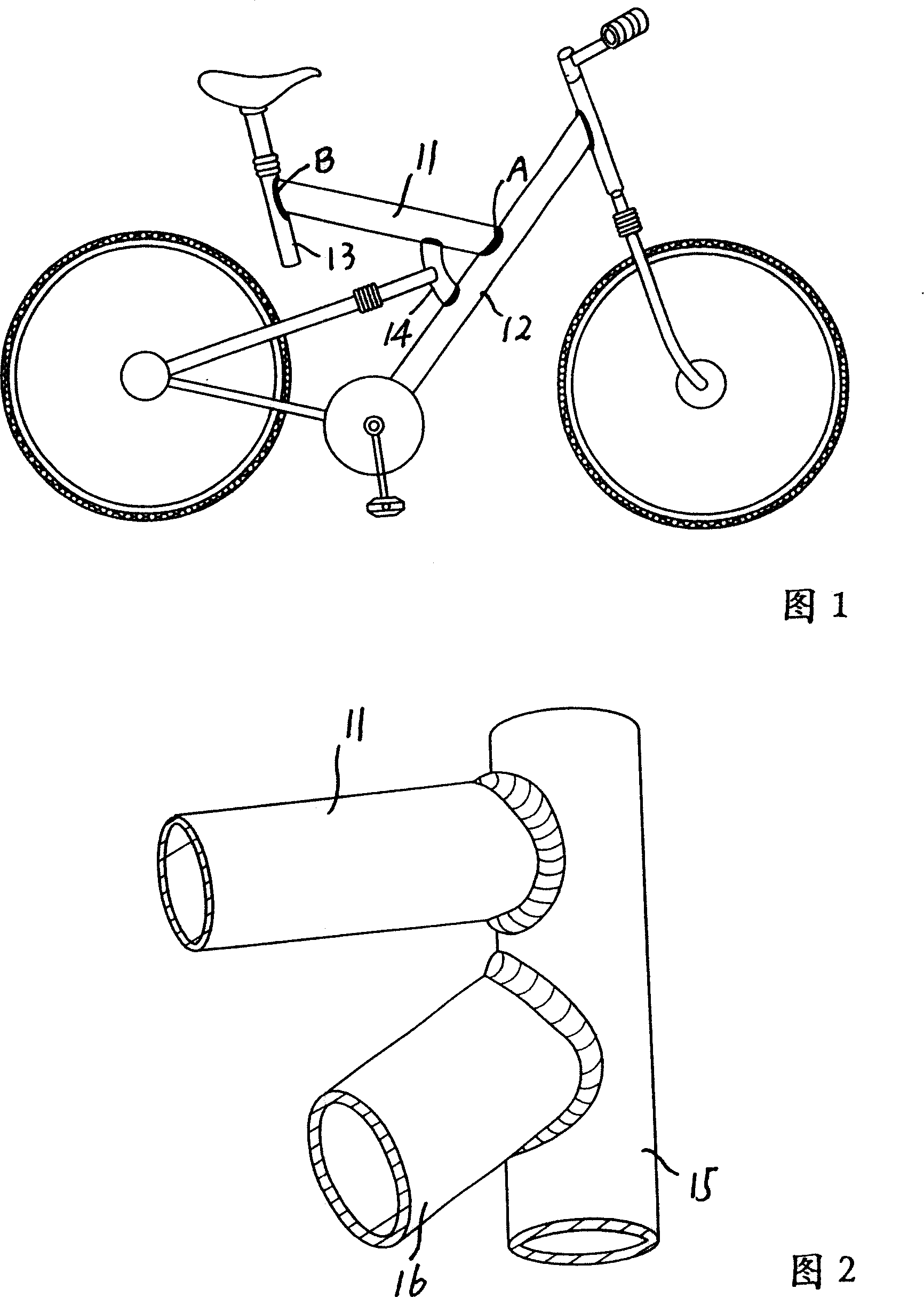

Sleeve type bicycle frame

A bicycle and sleeve-type technology, which is applied in the field of vehicle components, can solve the problems of restricting folding bicycles, reducing strength, and affecting the strength of welded parts of the frame.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

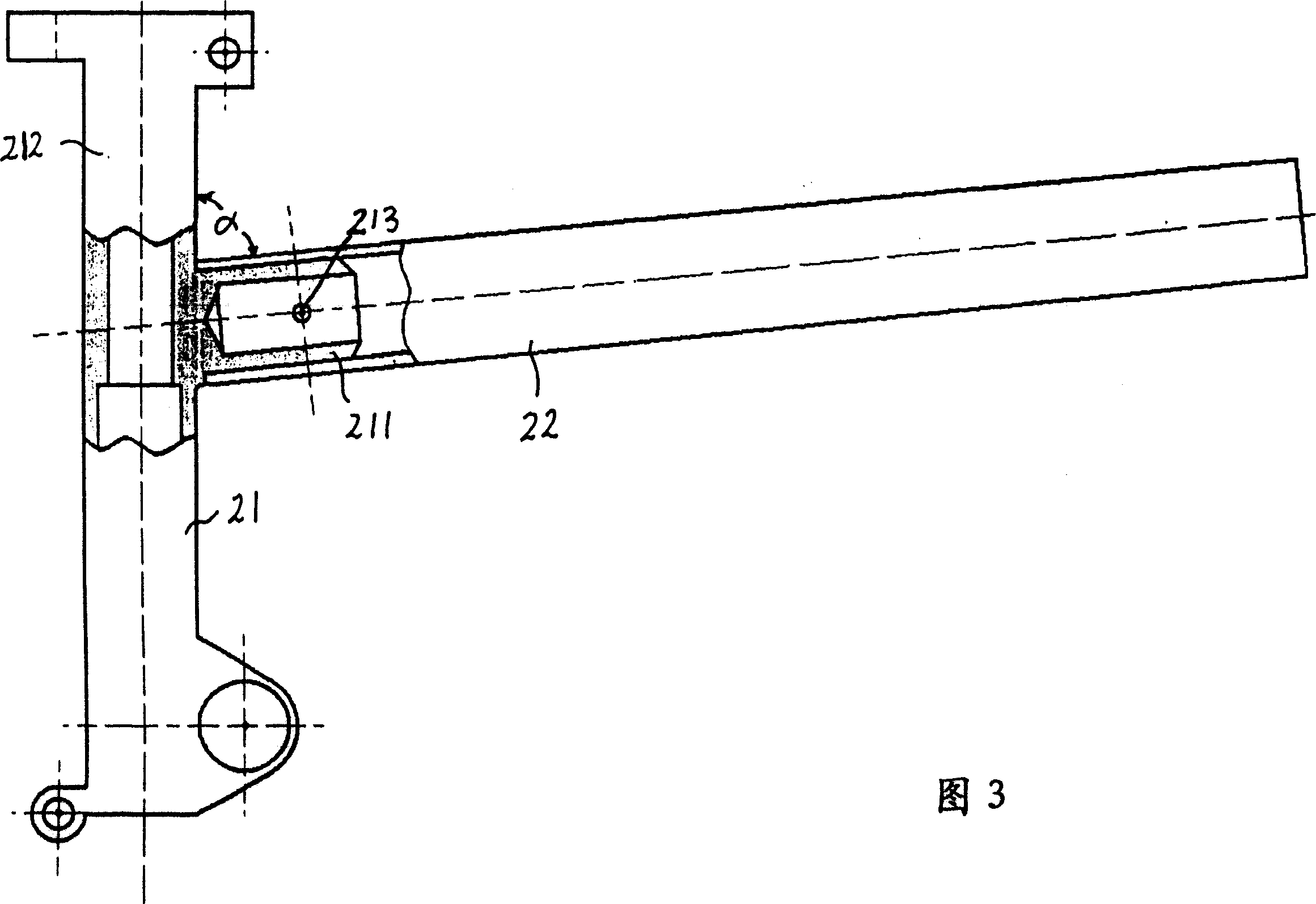

Embodiment 1

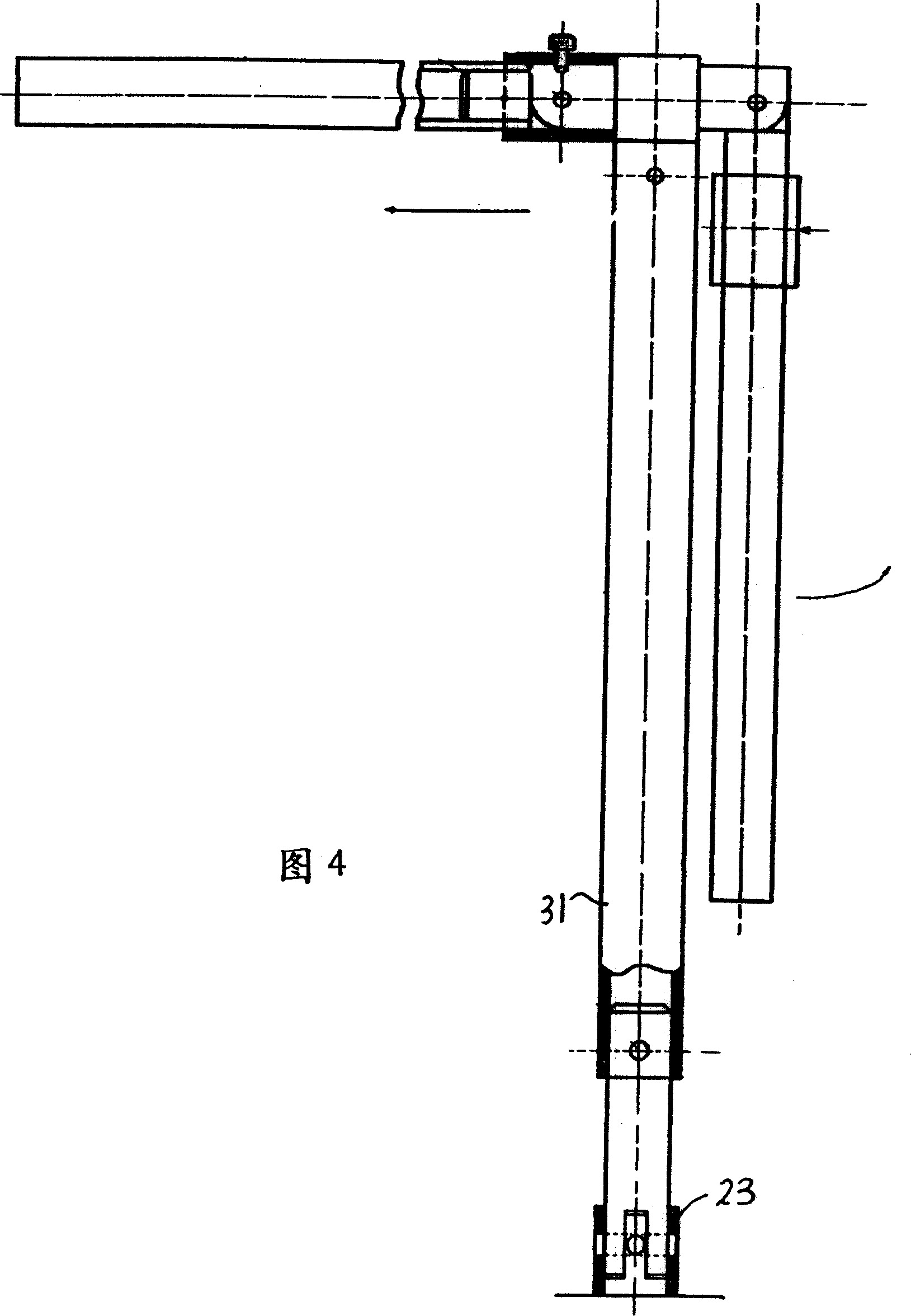

[0025] The sleeve type connection structure is specifically shown in Figure 3. Among the two connected bars of the sleeve type connection structure, one is a "male" bar 21, which is a vertical bar, and the other is a "female" bar. " bar 22, this root is a horizontal bar (this horizontal bar can be regarded as horizontal setting in this figure). The "male" bar 21 has a tenon 211 extending out of the bar body. The tenon 211 and the bar body 212 are integrally formed. The tenon 211 of the "male" bar is perpendicular to the bar body 212. The other "female" bar 22 It is a sleeve-type structure. The shape of the "female" bar matches the shape of the tenon 211 of the "male" bar and is inserted into the tenon 211. For example, if the tenon 211 is cylindrical, then " The female "bar 22 is also cylindrical, but the inner diameter of the "female" bar 22 is slightly larger than the outer diameter of the tenon 211, so that the tenon 211 of the "male" bar 21 and the sleeve of the "female" b...

Embodiment 2

[0027] The structure of this embodiment can also refer to shown in Fig. 3, same, one is " male " bar 21, and this root bar is vertical bar, and another is " female " bar 22, and this root is horizontal bar, and " male " The bar 21 has a tenon 211 extending out of the bar body, and the tenon 211 and the bar body 212 are integrally formed, but the angle α between the tenon 211 of the "male" bar and the bar body 212 in the vertical upward direction is less than 90 degrees . "Female" bar 22 is still a sleeve-type structure, and what is different from the previous embodiment is that "female" bar 22 has a certain angle with the horizontal line, which is a horizontal slash. The shape of the "female" bar 22 matches the shape of the tenon 211 of the "male" bar and is inserted into the tenon 211. For example, if the tenon 211 is cylindrical, the "female" bar 22 is also Cylindrical type, but the inner diameter of "female" bar 22 will be slightly larger than the outer diameter of tenon 2...

Embodiment 3

[0030] Similarly, referring to Fig. 3 and shown in Fig. 5, the vehicle frame can be provided with two or more "male" bars 21, 23, and at least one "female" bar 22, and in Fig. 3, another " Public " bar 23 is not illustrated, and Fig. 5 then shows another " public " bar 23 schematically, and the vehicle frame of this moment is then made of two " public " bars 21,23 and a " female " bar 22 . Each "male" bar (taking the "male" bar 21 as an example) has a tenon 211 extending out of the bar body, the tenon 211 and the bar body 212 are integrally formed, and the "female" bar 22 is a sleeve Type structure, the shape of the "female" bar 22 is adapted to the shape of the tenons of the two "male" bars, and its two ends are nested in the tenons of the two "male" bars.

[0031] Of course, the tenon 211 of the "male" bar 21 and the bar body 212 can also be vertical, or the angle between the tenon 211 of the "male" bar and the vertical direction of the bar body 212 is greater than 90 degree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com