High power compact thermostatic device without liquid cooling

A constant temperature device, compact technology, applied in refrigerators, refrigeration and liquefaction, temperature control using electric methods, etc., can solve the problems of large volume of constant temperature devices, high production costs, hidden dangers of liquid leakage, etc., and achieve easy industrialized mass production , compact structure, fast cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

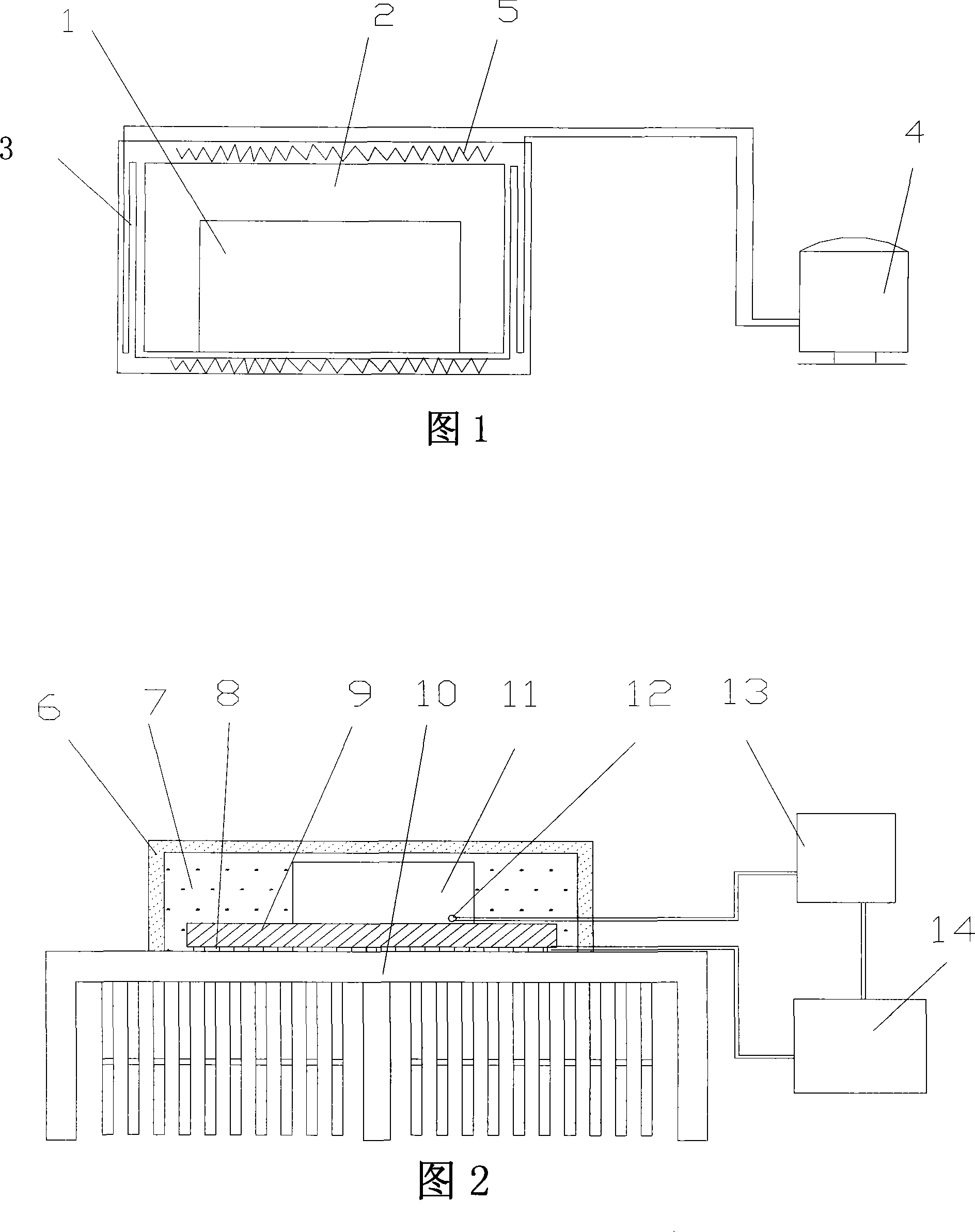

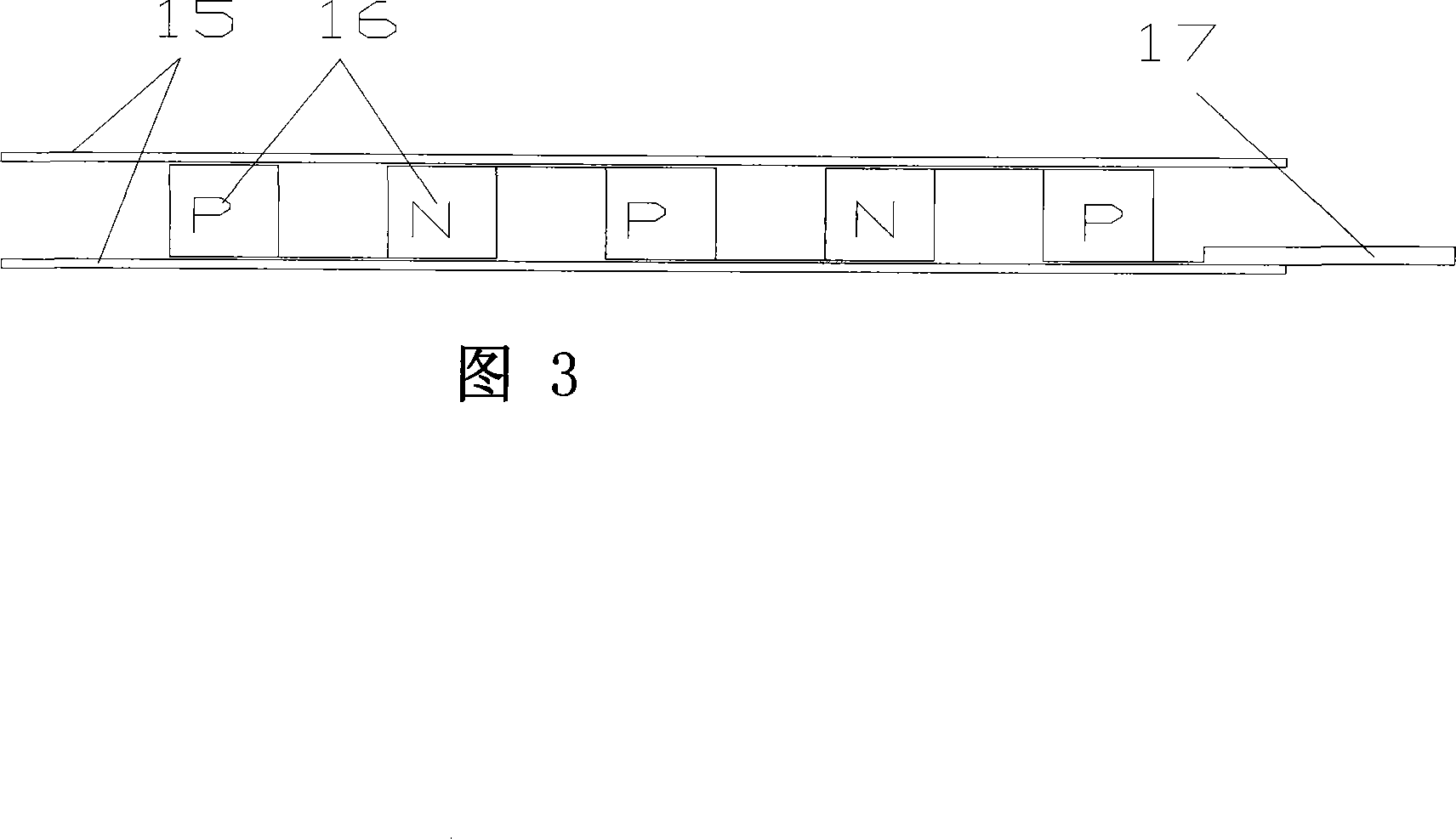

[0018] The specific embodiment of the high-power non-liquid-cooled compact constant temperature device referred to in the present invention is described as follows in conjunction with Fig. 2 and Fig. 3:

[0019] When the maximum laser output power of the diode laser 11 is 30W, about 40W of heat will be released at the same time. If the ambient temperature is 55°C, and the working temperature of the diode laser is lowered to 25°C within 10 minutes, a cooling capacity of about 20W, the thermal insulation box 6 dissipates about 10W, and requires a total cooling of about 70W. According to this cooling capacity, we select 3 (tiled) semiconductor thermoelectric devices 8 with a maximum cooling capacity of 120W, and a radiator 10 with a thermal resistance of less than 0.05K / W (note: when the ambient temperature reaches 55°C and the radiator heat When the resistance is less than 0.05K / W, the actual cooling capacity of each semiconductor thermoelectric device is 25W), the insulation bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com