Small core diameter ultra-high numerical aperture cone optical fiber optical tweezers and manufacturing method thereof

A technology of numerical aperture and optical fiber optical tweezers, applied in the field of optical fiber, can solve problems such as difficulty in maintaining the consistency of optical and mechanical properties, and insufficient structural strength, and achieve the effects of ensuring standardization and consistency, simple structure, and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

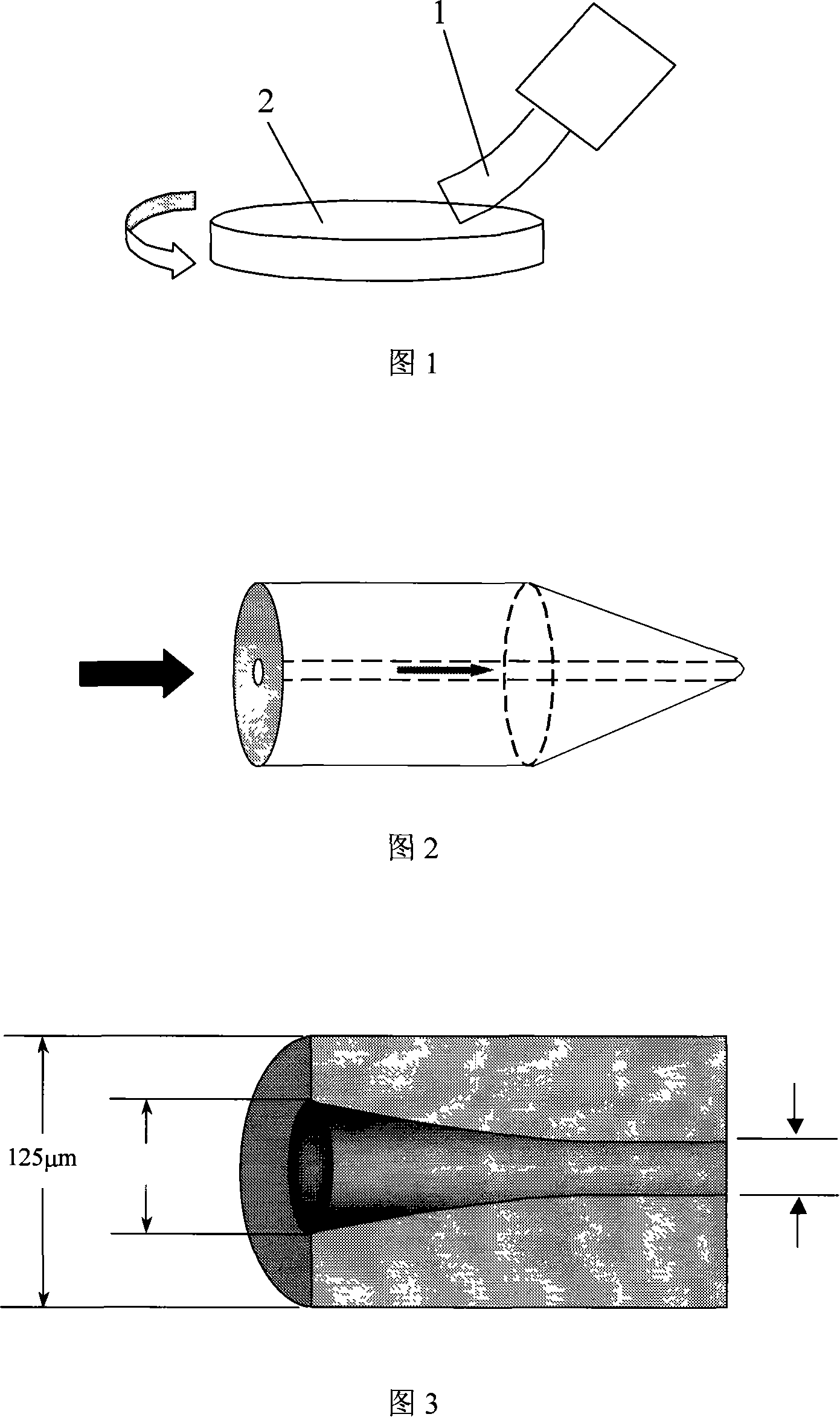

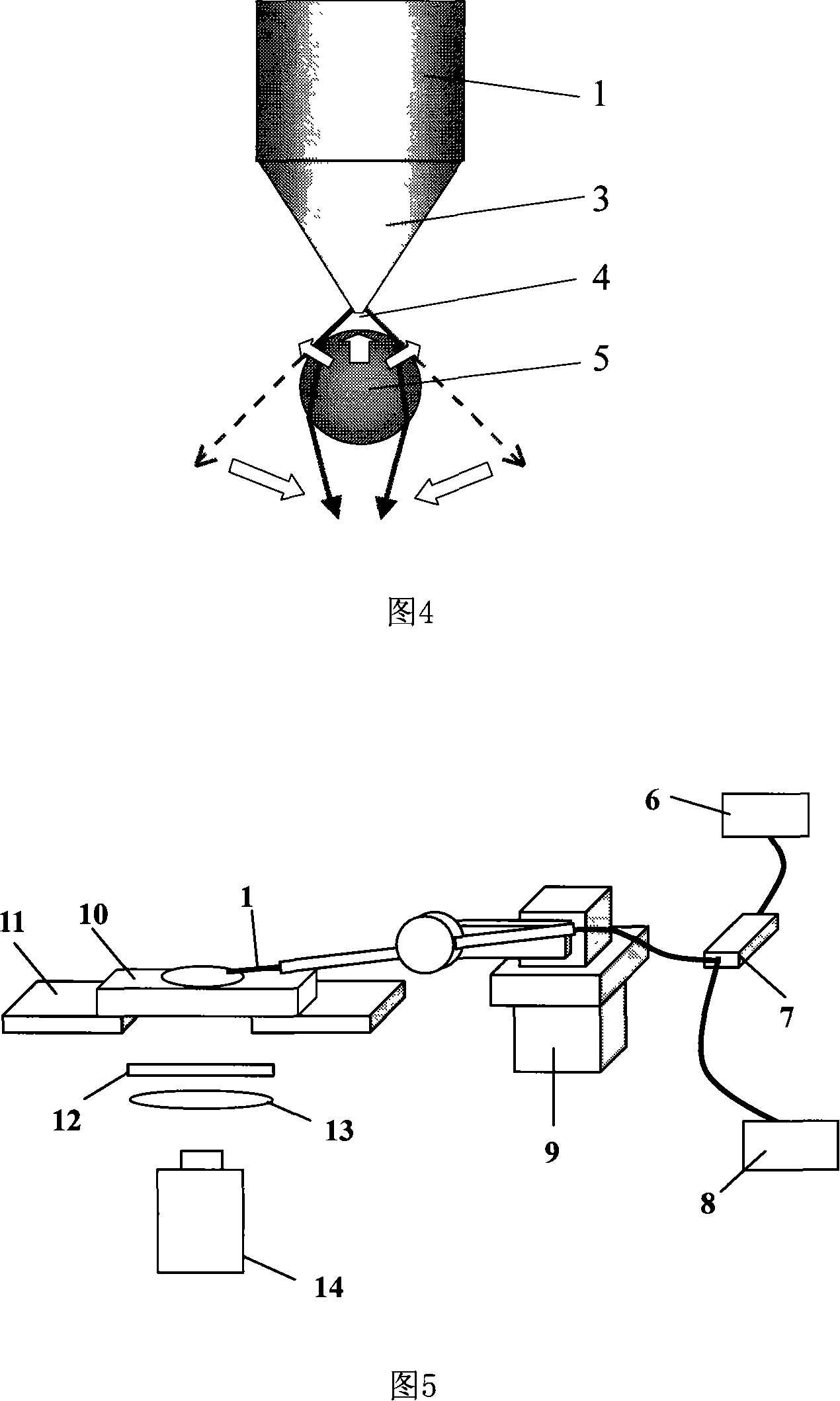

[0040] Embodiment: Use small core diameter ultrahigh numerical aperture cone fiber optical tweezers to realize the transportation of tiny objects.

[0041] The preparation method of the small core diameter super high numerical aperture cone optical fiber optical tweezers of this embodiment is as follows:

[0042]1. Preparation or selection of optical fiber: The numerical aperture of ordinary standard single-mode silica optical fiber for optical fiber communication is generally about 0.11, and the maximum divergence angle corresponding to the optical fiber exit light field in air is about 6.32°, and in water, it is about 4.74°. Therefore, the gradient force potential well of the formed divergent light field is relatively shallow, which is not enough to overcome the gravity of the particles. When the present invention is making optical fiber optical tweezers, on the one hand, an optical fiber with small core diameter and ultra-high numerical aperture will be prepared or selected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com