Backlight drive having isolated form power factor correcting structure and control circuit thereof

A backlight drive and control circuit technology, applied to static indicators, instruments, etc., can solve the problems of increasing the number of optical coupling components and threats to user safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

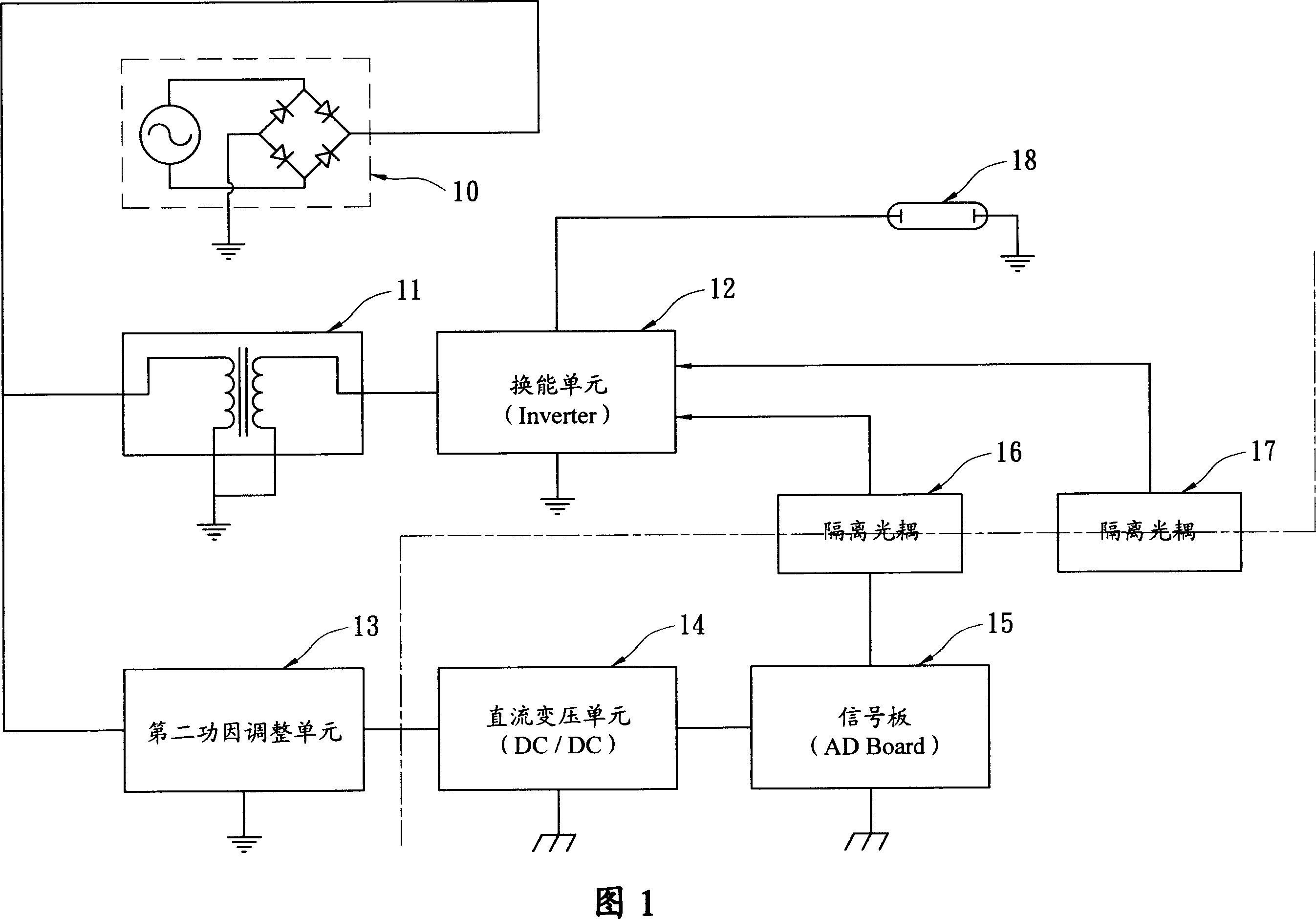

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

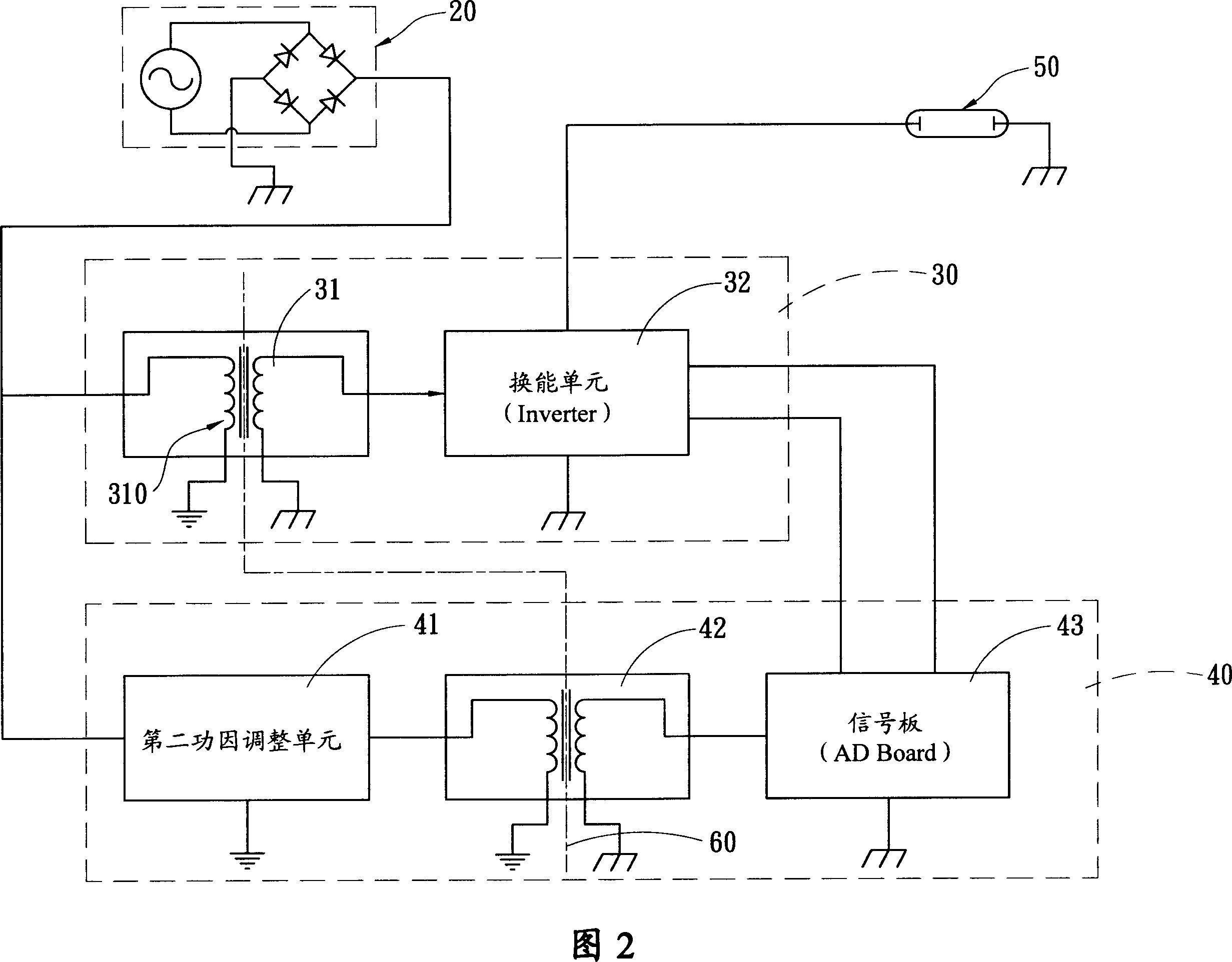

[0012] The circuit architecture of the preferred embodiment of the present invention, as shown in FIG. 2, includes:

[0013] Power Stage 20 (Power Stage) is used to provide power, which converts the city power (AC power) into the DC power required by the device. The power specifications of the city power are different according to the power specifications of each country (for example, AC-110V or AC-220V). Generally speaking, the so-called power stage 20 can be equipped with an electromagnetic interference filter unit (EMI) and a bridge rectifier composed of diodes, which are used to filter and rectify the alternating current and output a full / half wave DC power supply (the electromagnetic interference filter unit (EMI) among them needs to be determined according to the specifications of the power system in various countries);

[0014] The driver stage (Driver Stage) 30 has a first power factor adjustment unit 31 for adjusting the power factor of the power supply and outputting a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com