Laser product with bar code and manufacturing process thereof

A bar code and product technology, applied to record carriers, instruments, computer parts, etc. used in machines, can solve the problems of poor printing effect, economic loss of printing enterprises, overprinting waste and other problems, achieve simple aluminum plating process, reduce production costs, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

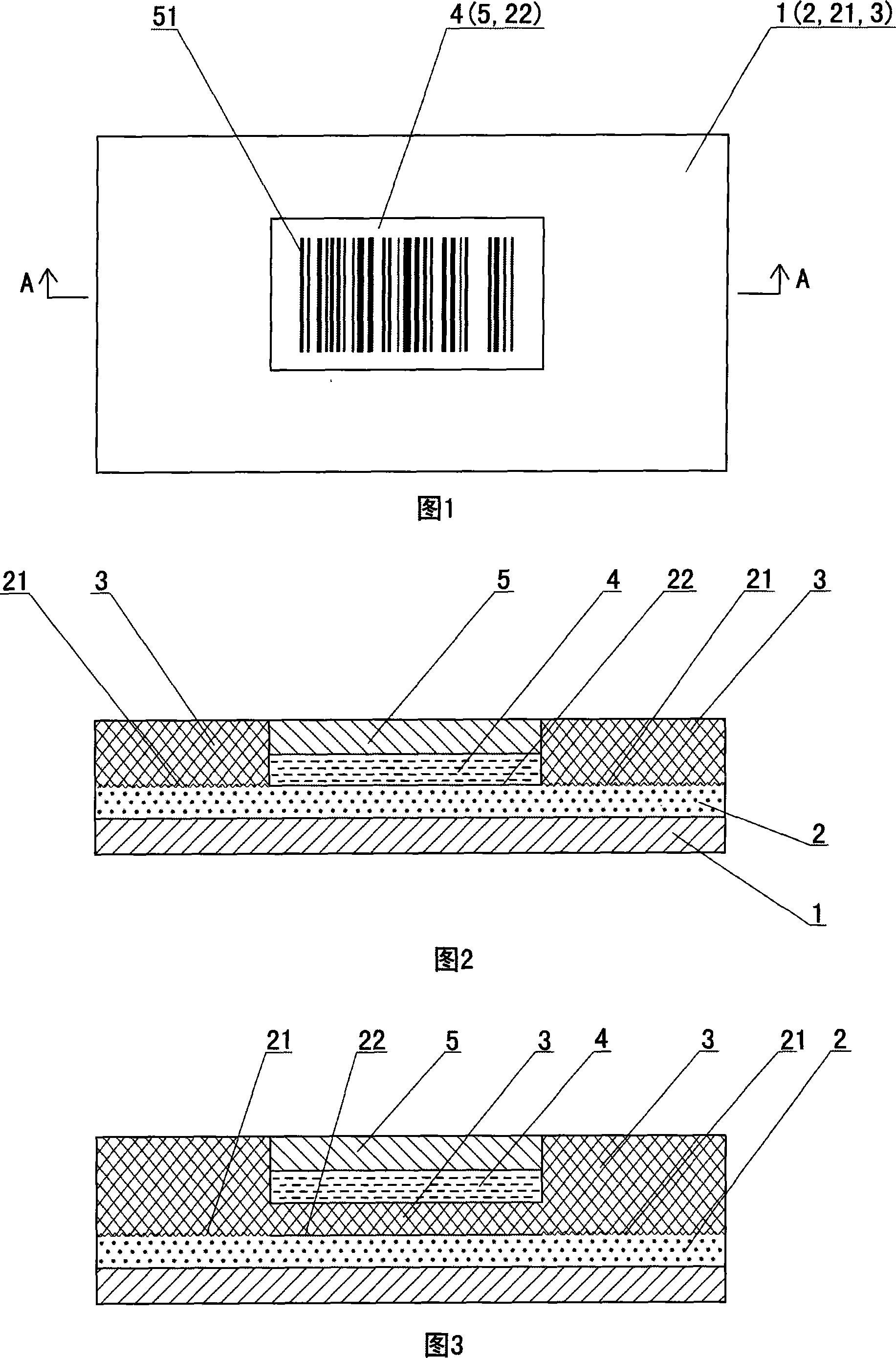

[0028] As shown in Fig. 1 and Fig. 2, the laser product with barcode in the present preferred embodiment comprises base material 1, and one surface of base material 1 is provided with release layer 2, and the upper surface of release layer 2 is made of The micro-concave-convex surface part 21 and the smooth surface part 22 are formed, and the aluminum-plated layer 3 is provided on the micro-concave-convex surface part 21, and an ink layer 4 is provided on the smooth surface part 22, and a barcode layer 5 is provided on the ink layer 4.

[0029] Since the upper surface of the release layer 2 is composed of a fine concave-convex surface part 21 and a smooth surface part 22, the fine concave-convex surface part 21 of the release layer 2 is provided with an aluminum coating 3, and the fine concave-convex surface can conduct incident light. Strong reflection, so the release layer 2 has a fine concave-convex surface portion 21 that can produce a laser effect; since the smooth surface...

Embodiment 2

[0040] Embodiment 2 is basically the same as Embodiment 1, the difference between the two is:

[0041] As shown in FIG. 3 , in Embodiment 2, an aluminum-plated layer 3 is also provided between the smooth surface portion 22 of the release layer 2 and the ink layer 4 of the laser product with the barcode.

[0042] Since the release layer 2 has a fine concave-convex surface part 21 and a smooth surface part 22, it is provided with an aluminum coating 3, that is, the entire release layer 2 is provided with an aluminum coating 3, and the release layer 2 has a fine concave-convex surface part. Laser effect can be produced on 21, there is no laser effect on the smooth surface part 22 of release layer 2 but only aluminum coating layer 3, like this, barcode layer 5 is printed on the aluminum coating layer 3 on the smooth surface part 22 of release layer 2, The contrast between the barcode 51 of the barcode layer 5 and the ink layer 4 as the background color is large, so the printing qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com