Multifunctional tester for shape memory alloy wire material

A technology of memory alloy wire and tester, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., to achieve the effects of small size, high measurement accuracy and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

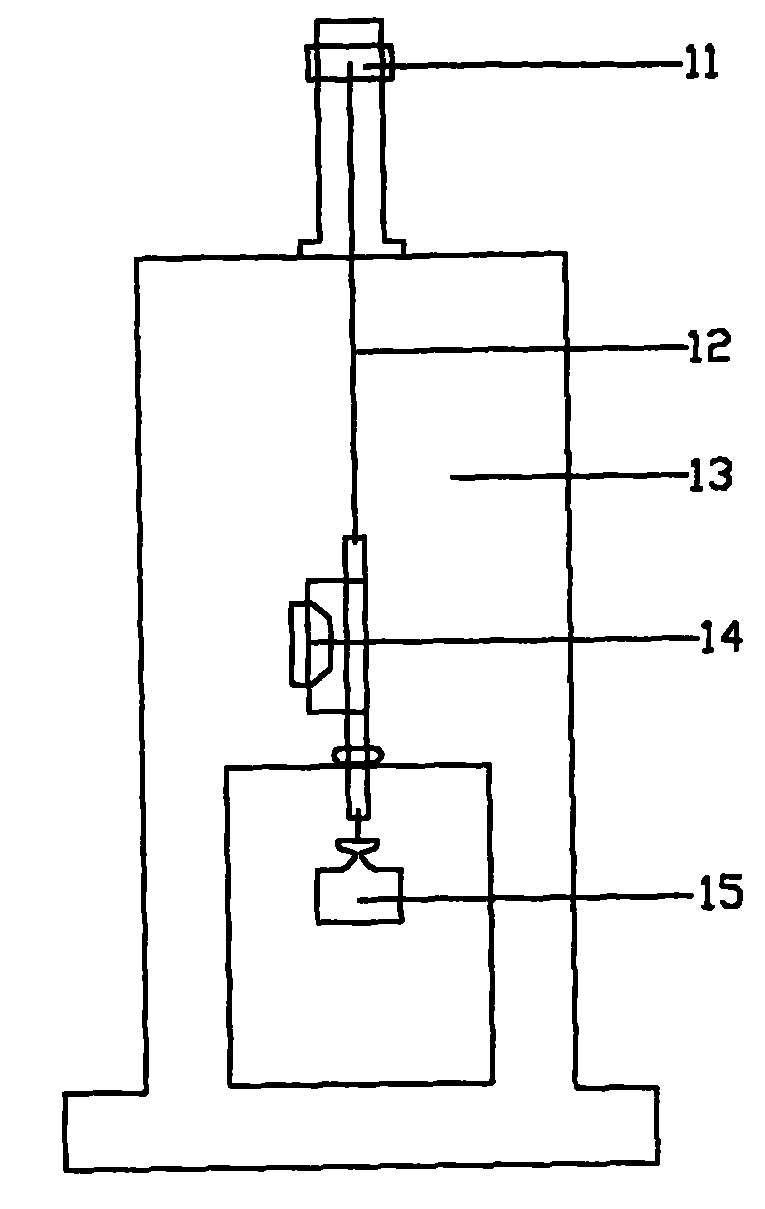

[0031] Test memory alloy fatigue decay under the measurement recovery rate and constant load of embodiment 1

[0032] As shown in Figure 1, it is a schematic diagram of measuring recovery rate and test memory fatigue attenuation performance under constant load for one embodiment of the multifunctional tester for shape memory alloy wire of the present invention; wherein: 11 is a movable upper sleeve; 12 is a shape memory alloy wire; 13 is the main frame; 14 is a displacement sensor; 15 is a weight. The effect of movable upper cover 11 is that it can be transferred up and down, and it is fixed on the main frame when it is transferred to an appropriate position, so that shape memory alloy wires of different lengths can be measured. The upper end of the shape memory alloy wire 12 is fixed on the movable upper sleeve 11, the lower end of the shape memory alloy wire 12 is connected with the weight 15 through a code chip, and the displacement sensor 14 includes a linear incremental o...

Embodiment 2

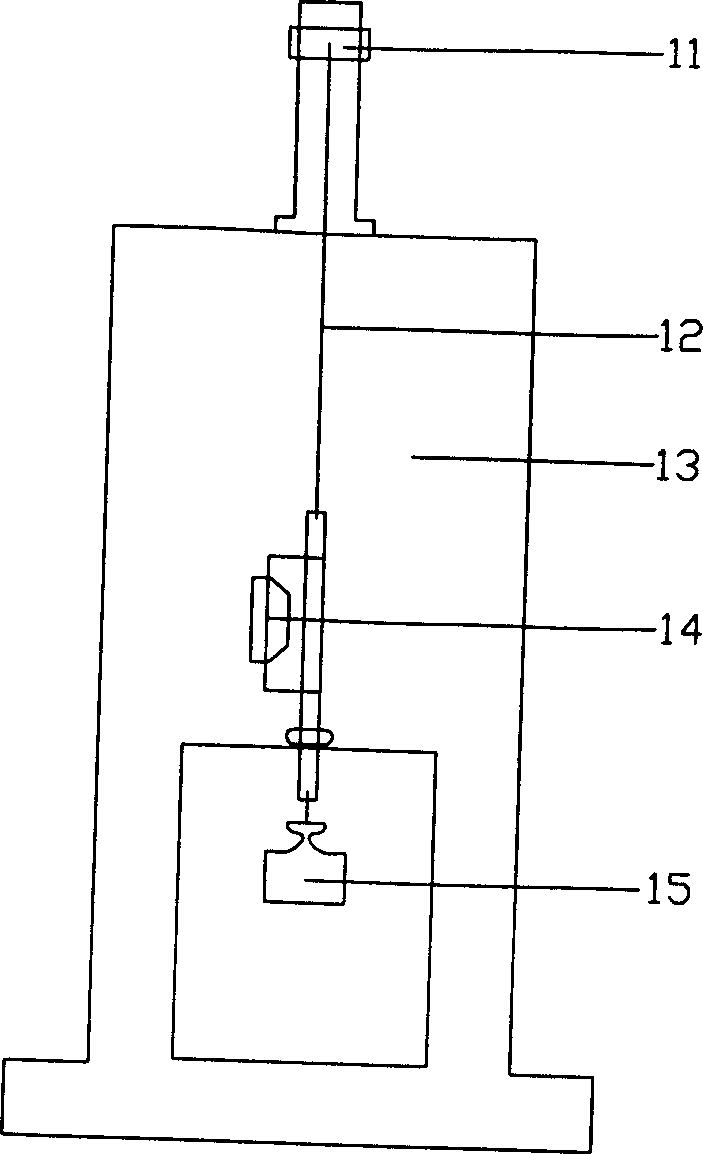

[0037] Embodiment 2 measures restoring force

[0038] As shown in Figure 2, it is a schematic diagram of measuring the restoring force of the second embodiment of the multifunctional tester for the shape memory alloy wire of the present invention; wherein: 21 is a movable upper sleeve; 22 is a shape memory alloy wire; 23 is the main frame ; 24 is a force sensor. The effect of movable upper cover 21 is to transfer up and down, and it is fixed on the main frame when transferred to a suitable position, so that shape memory alloy wires of different lengths can be measured. The upper end of the shape memory alloy wire 22 is fixed on the movable upper sleeve 21 , and the lower end is connected with the force sensor 24 . The signal output end of the force sensor 24 is connected with an external circuit, and the external circuit is not marked in the figure.

[0039] The specific test steps are as follows:

[0040] (1) Measure the length L1 of the shape-memory alloy wire 22 in a fre...

Embodiment 3

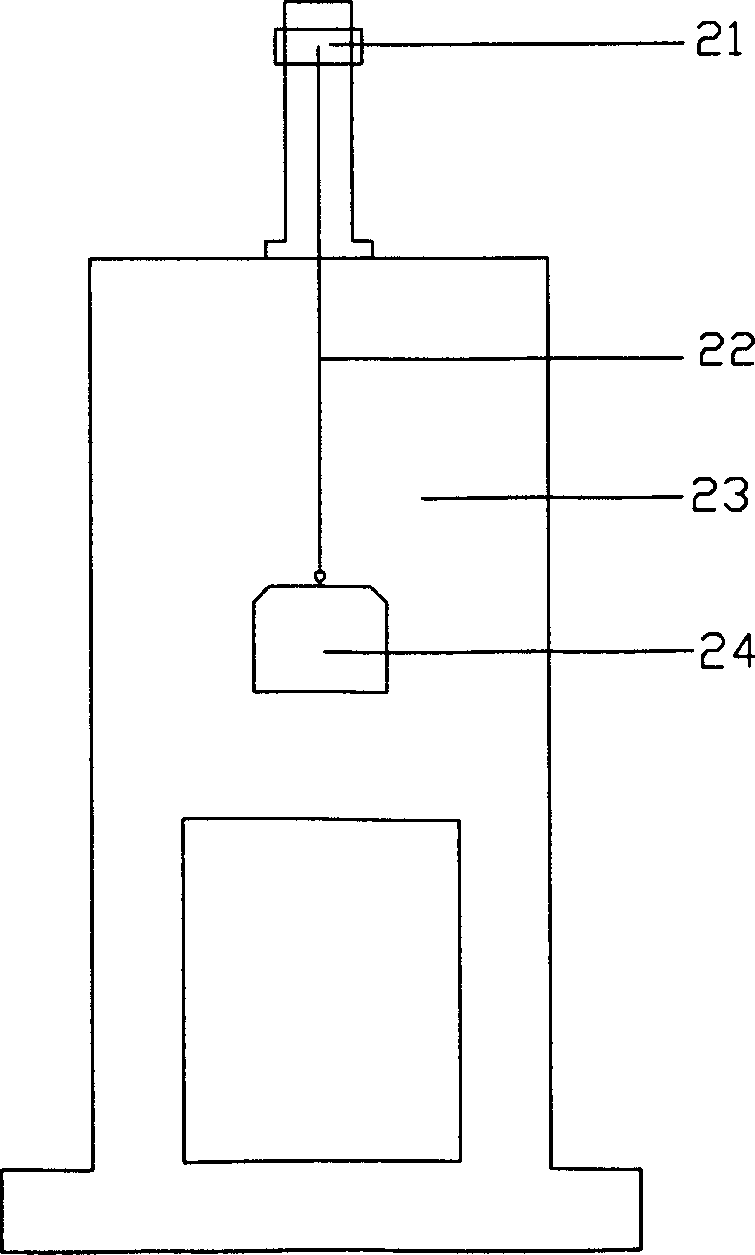

[0043] Example 3 Testing the driving performance of the shape memory alloy coupling body system

[0044] As shown in Figure 3, the schematic diagram of the third embodiment of the multifunctional tester for shape memory alloy wire of the present invention to test the driving performance of the shape memory alloy coupling body system, wherein: 31 is a movable upper sleeve; 32 is a shape memory alloy wire Material; 33 is the main frame; 34 is a displacement sensor; 35 is a spring; 36 is a force sensor. The effect of movable upper cover 31 is to transfer up and down, and it is fixed on the main frame when transferred to a suitable position, so that shape memory alloy wires of different lengths can be measured. The upper end of the shape memory alloy wire 32 is fixed on the adjustable upper sleeve 31 , the lower end of the memory alloy wire 32 is connected with the upper end of the spring 35 through the chip of the displacement sensor, and the lower end of the spring 35 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com