Filtering electrical sensor

A technology for filtering inductors and windings, applied in the field of inductors, can solve the problems of increased manufacturing cost and high difficulty of winding frames, and achieves the effects of improving the degree of freedom, saving wiring space, and improving the value of differential mode inductance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

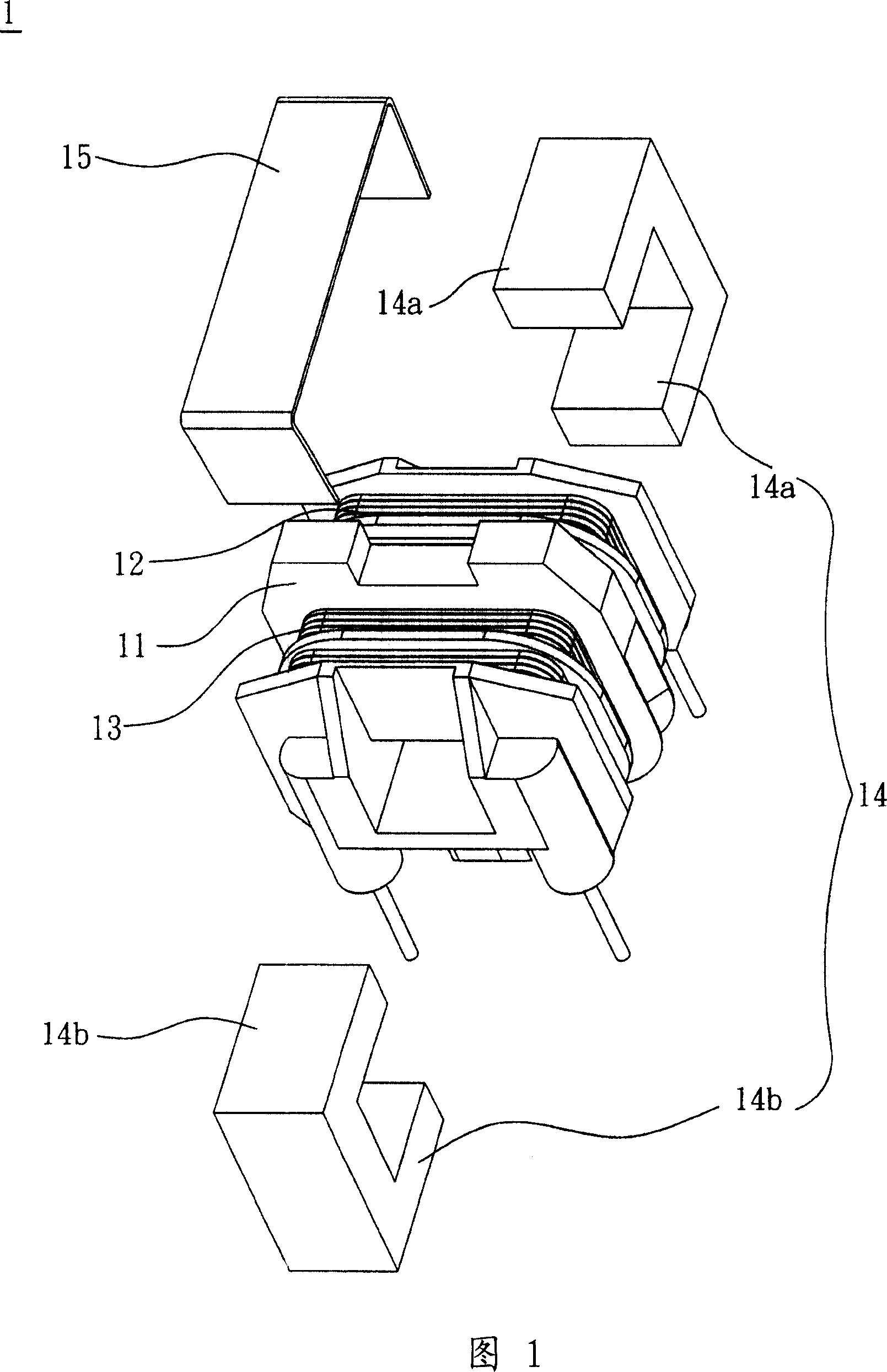

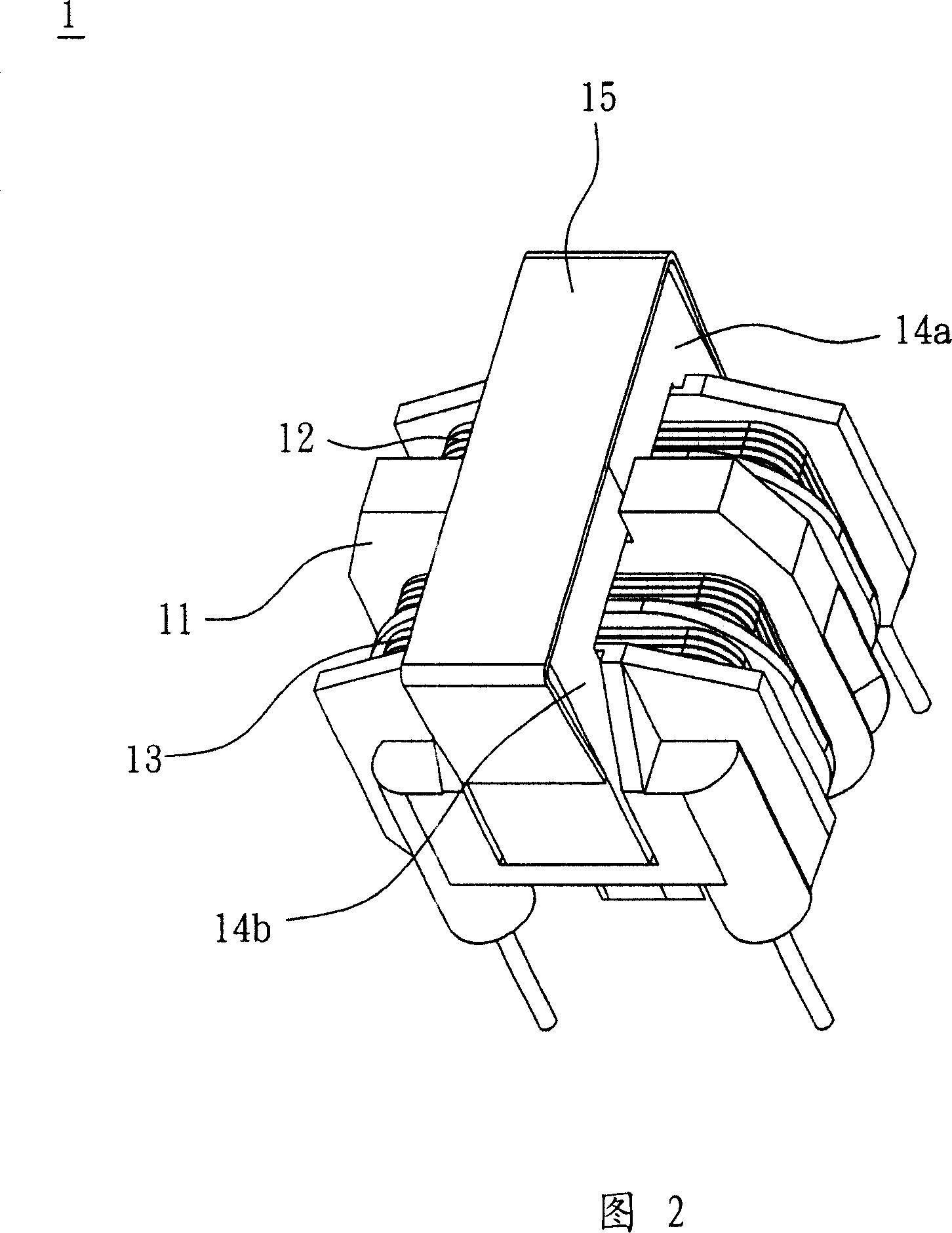

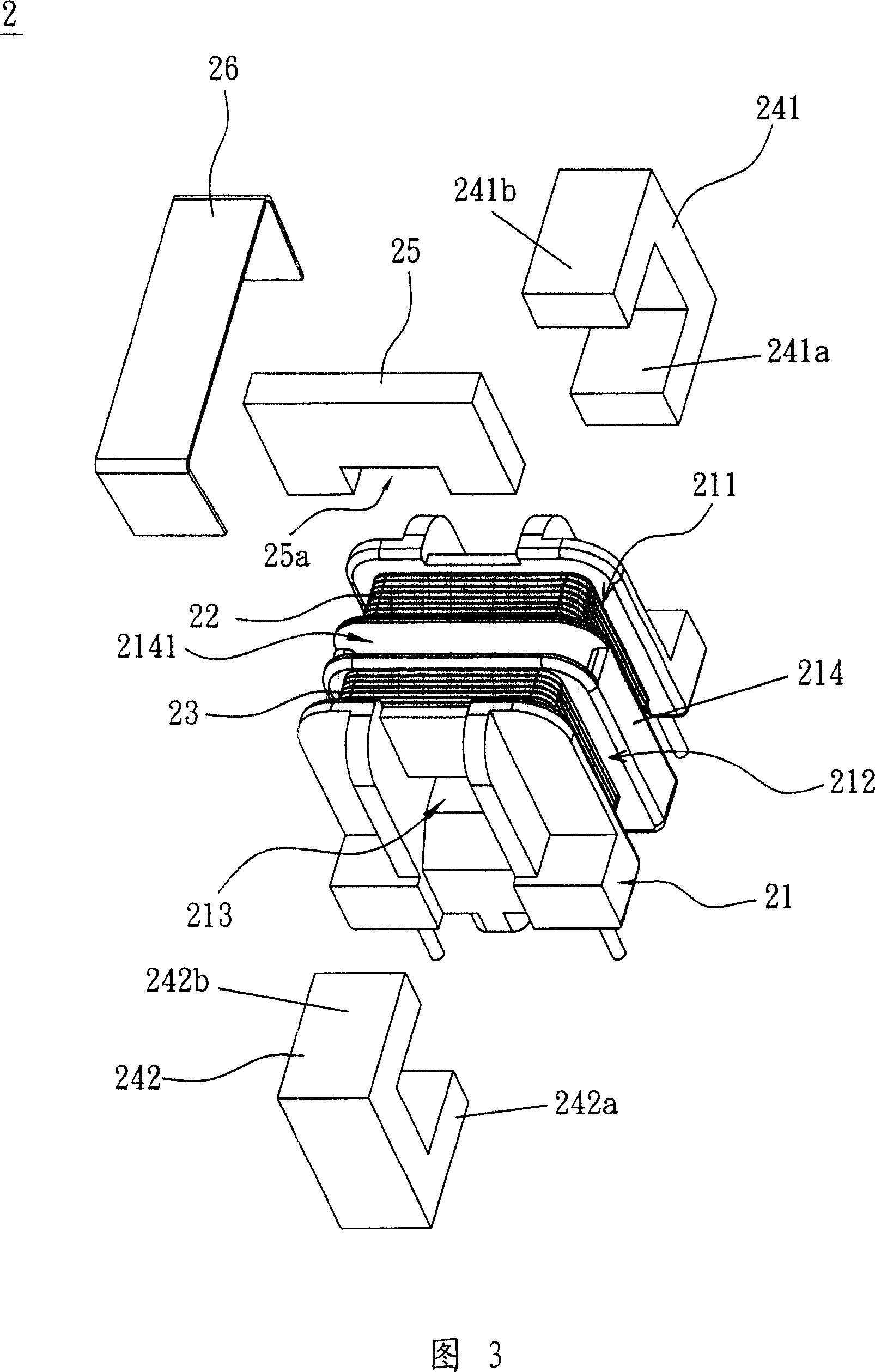

[0031] A filter inductor according to a preferred embodiment of the present invention will be described below with reference to related drawings, wherein the same elements will be described with the same reference symbols.

[0032] 3 and 4, according to a preferred embodiment of the present invention, a filter inductor 2 includes a bobbin 21, a first winding 22, a second winding 23, a core group 24 and a Magnetic conductor 25.

[0033] In this embodiment, the bobbin 21 has a first winding area 211 , a second winding area 212 and an isolation portion 214 . The isolation portion 214 is located between the first winding area 211 and the second winding area 212 and has a slot 2141 therein. The bobbin 21 also has a through hole 213 passing through the isolation portion 214 , the first winding area 211 and the second winding area 212 . The material of the bobbin frame 21 in this embodiment is not limited, but in practice, non-magnetic material is preferred, such as but not limited...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com