Sealing structure using gasket

A sealing structure and gasket technology, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of uneven deformation of the cover body, insufficient surface pressure of the gasket, and achieve high reliability, easy installation, and easy installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

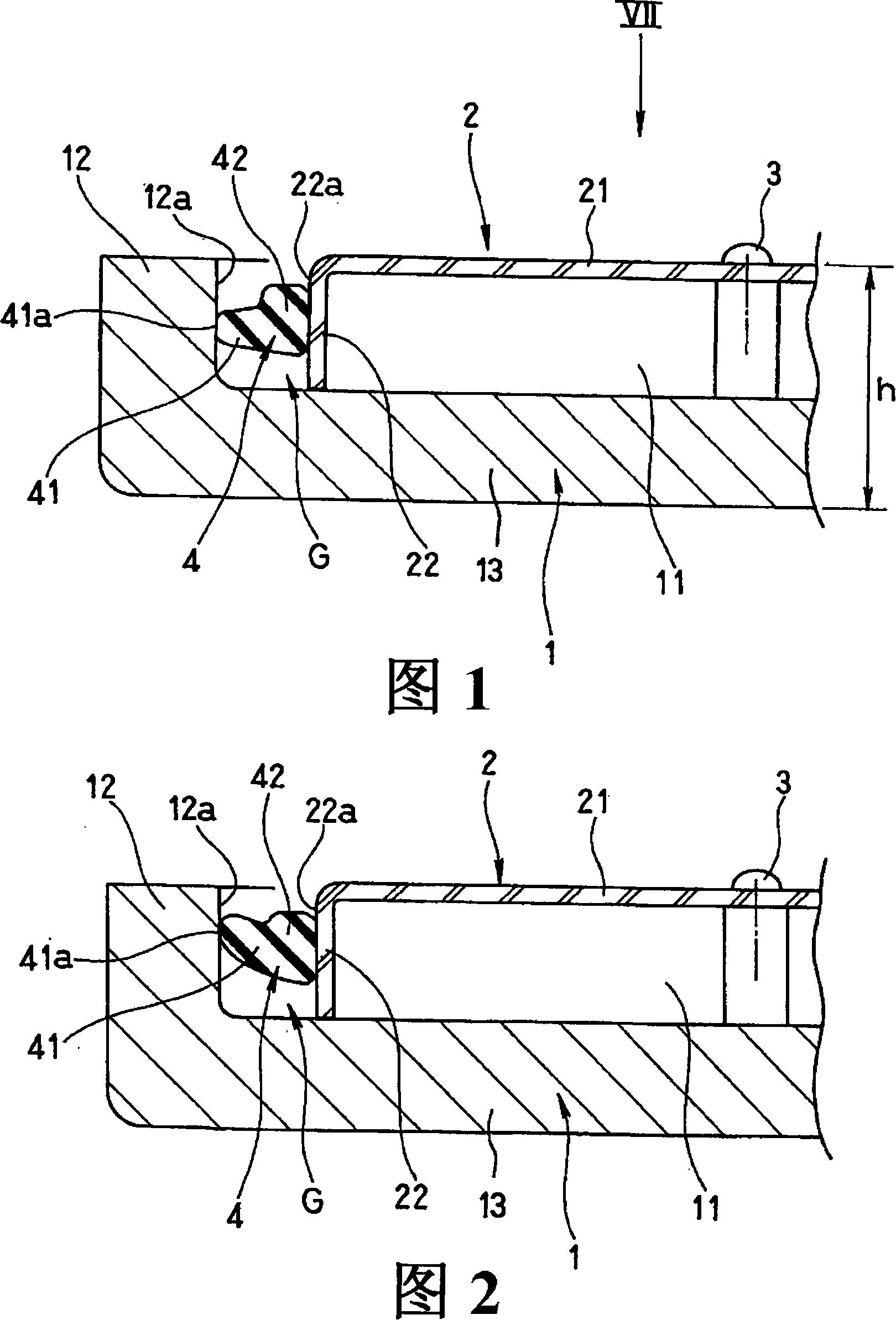

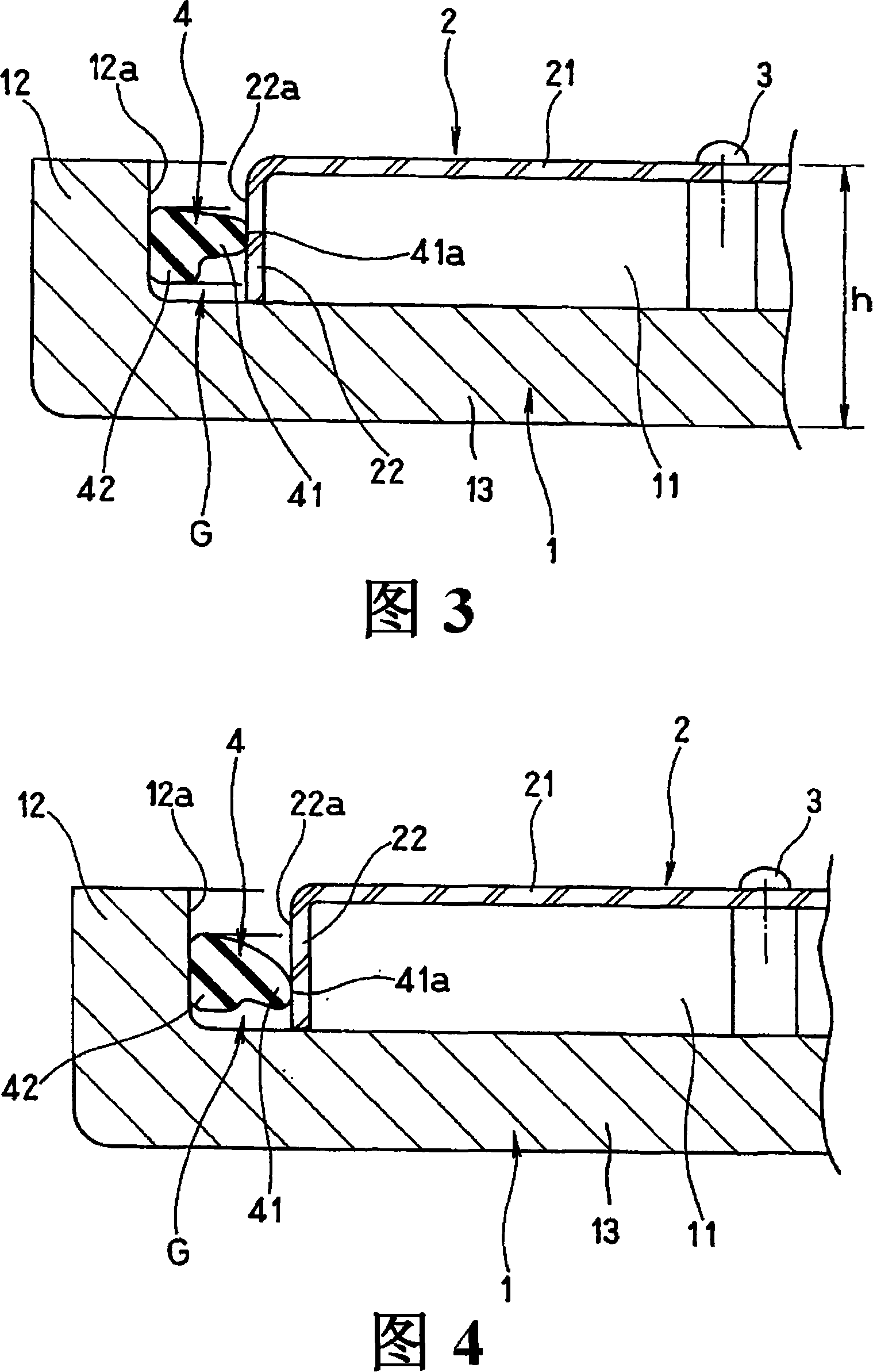

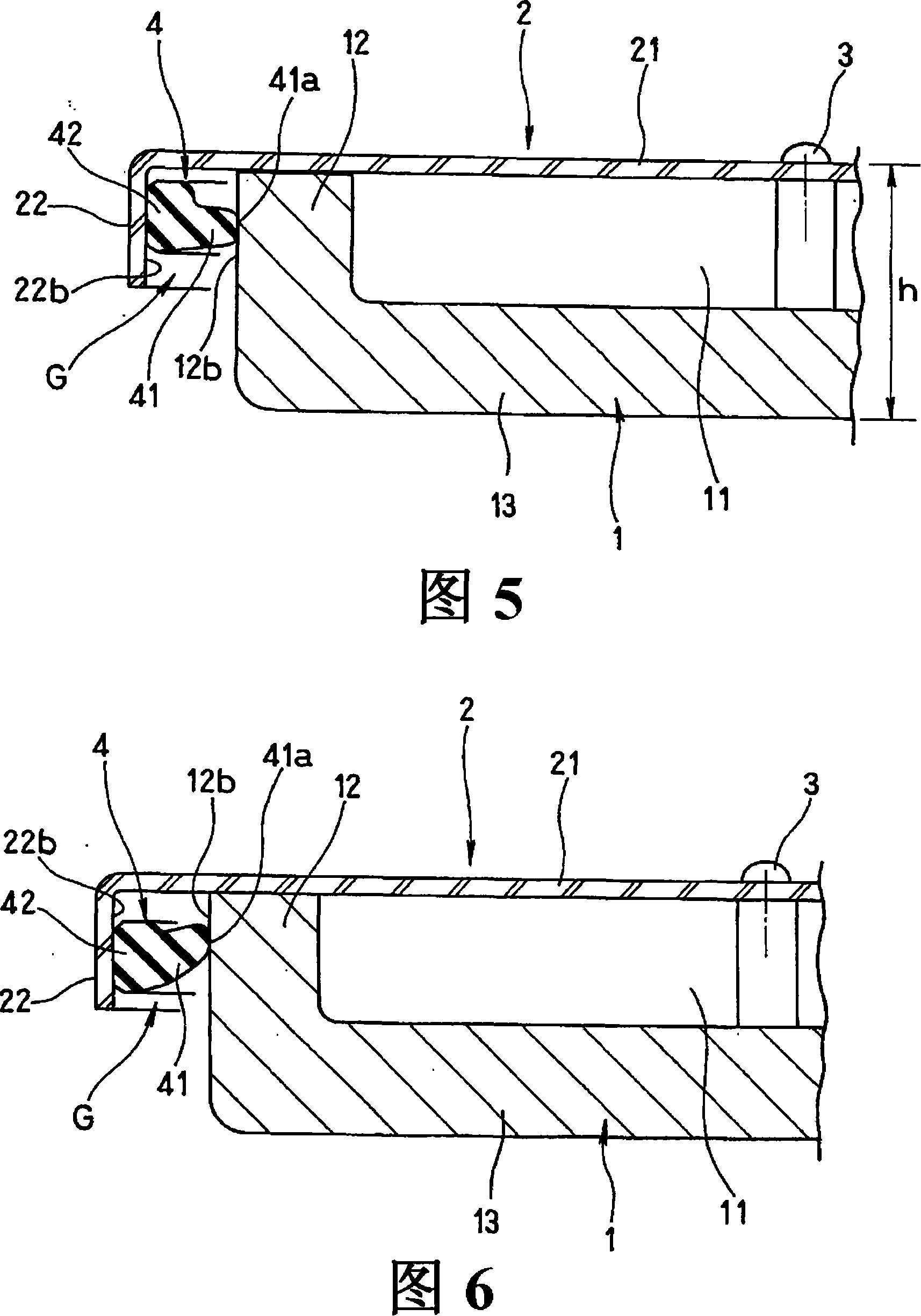

[0088] Fig. 1 is a partial cross-sectional view showing the first embodiment of the gasket sealing structure according to the present invention; The base of the accommodation portion 11 that can accommodate the unillustrated magnetic disk, magnetic head and its driving device; symbol 2 represents the cover that seals the above-mentioned accommodation portion 11 to the base 1 by a plurality of screw parts 3, and the base 1 and the cover 2 constitutes the housing of the HDD.

[0089] The cover body 2 can be made of a metal plate such as stainless steel or aluminum by stamping, and is composed of an upper plate portion 21 and a side plate portion 22 formed by bending substantially vertically along its outer periphery. And, the cover body 2 is embedded in the receiving portion of the base 1, that is, the side plate portion 22 of the cover body 2 is located on the inner peripheral side of the side plate portion 12 of the base 1, and the outer surface 22a of the side plate portion 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com